Improving structure of rotor

A technology to improve the structure and rotor, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems such as the inability to effectively display the heat dissipation effect, the reduction of the fluid velocity, and the obstruction of the outward flow of the fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

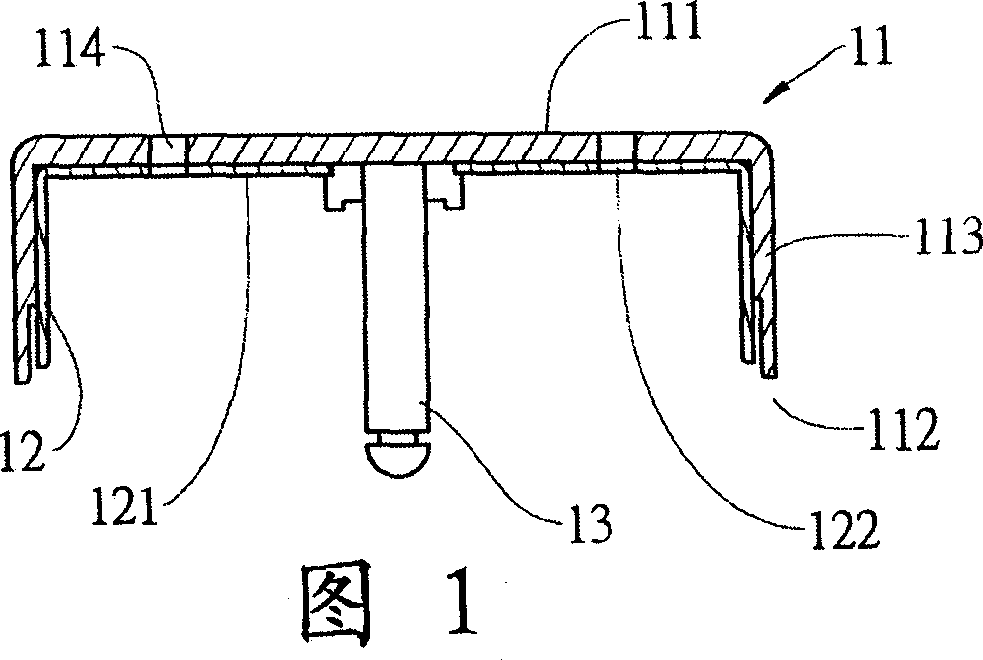

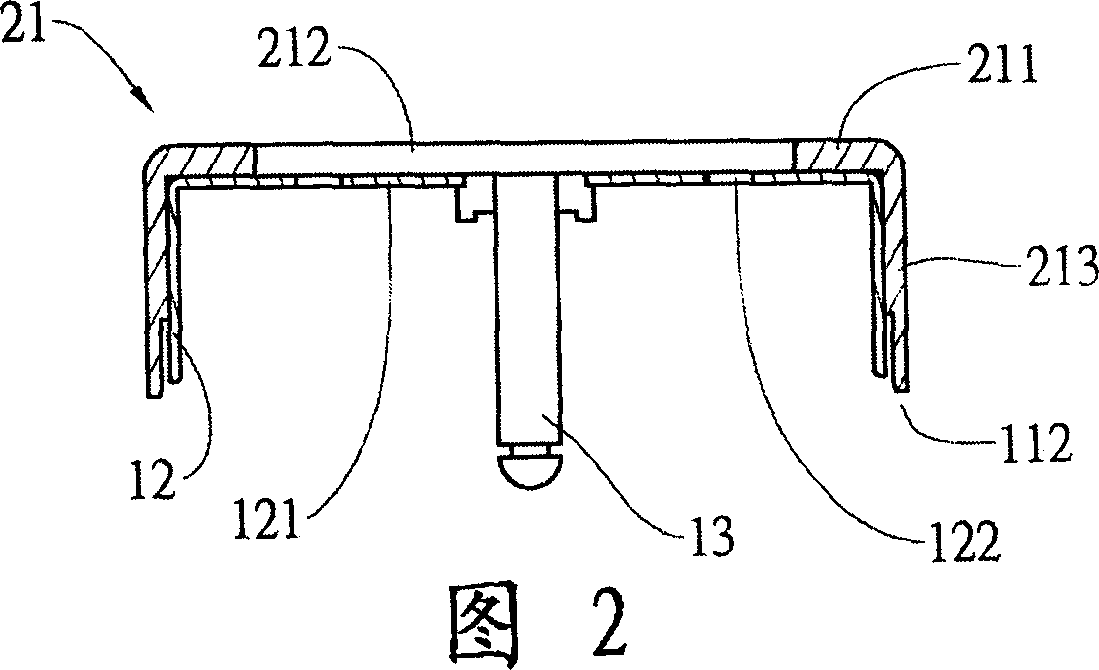

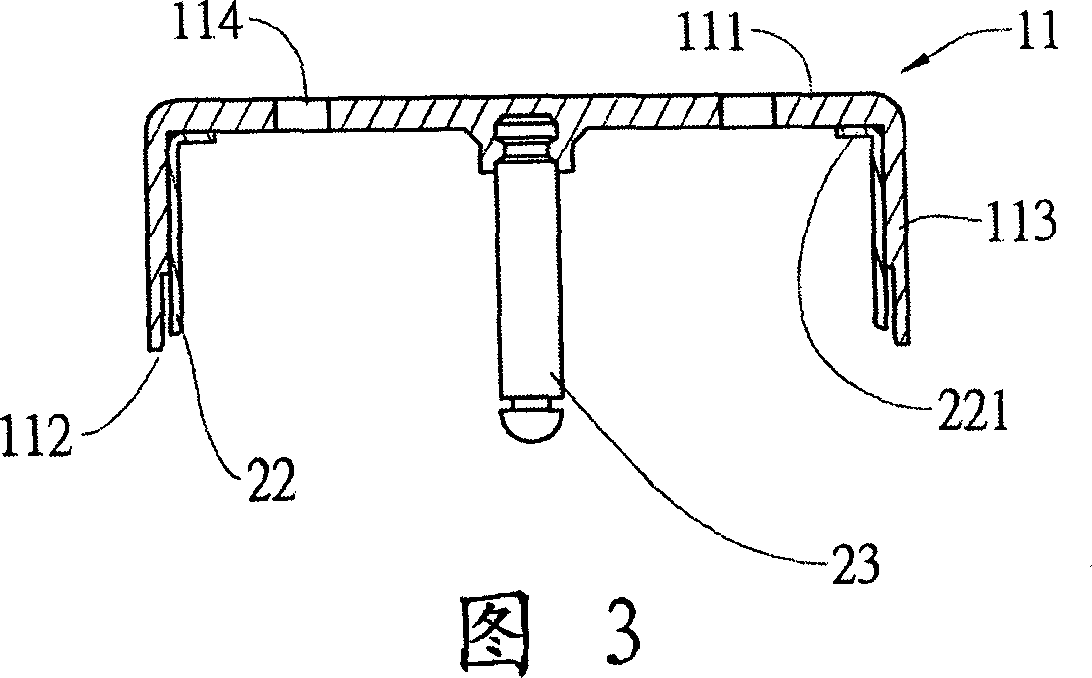

[0021] The present invention provides an improved structure of a rotor. The accompanying drawings are preferred embodiments of the present invention. Please refer to FIG. 4 and FIG. 5, which are the first preferred embodiment of the present invention. A housing 32, wherein the hub 31 has a closed end 311, an open end 312 and a side wall 313 connected between the closed end 311 and the open end 312, and the outer surface of the closed end 311 is provided with at least a second A through hole 314, the inner surface of the closed end 311 is provided with at least a second through hole 315, and a flow channel 316 is communicated between the first through hole 314 and the second through hole 315, and the inner wall of the flow channel 316 is inclined, and in this preferred embodiment, the first through hole 314, the second through hole 315 and the passage 316 are radially arranged and the inner wall of the passage 316 is inclined toward the outside of the hub 31, but the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com