Simple pendulum variable-pitch beam-balanced pump

A beam pumping unit and single pendulum technology, which is applied in mechanical equipment, non-electrical variable control, and production of fluids, etc., can solve the problem of not being in the best energy-saving state of the pumping unit, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

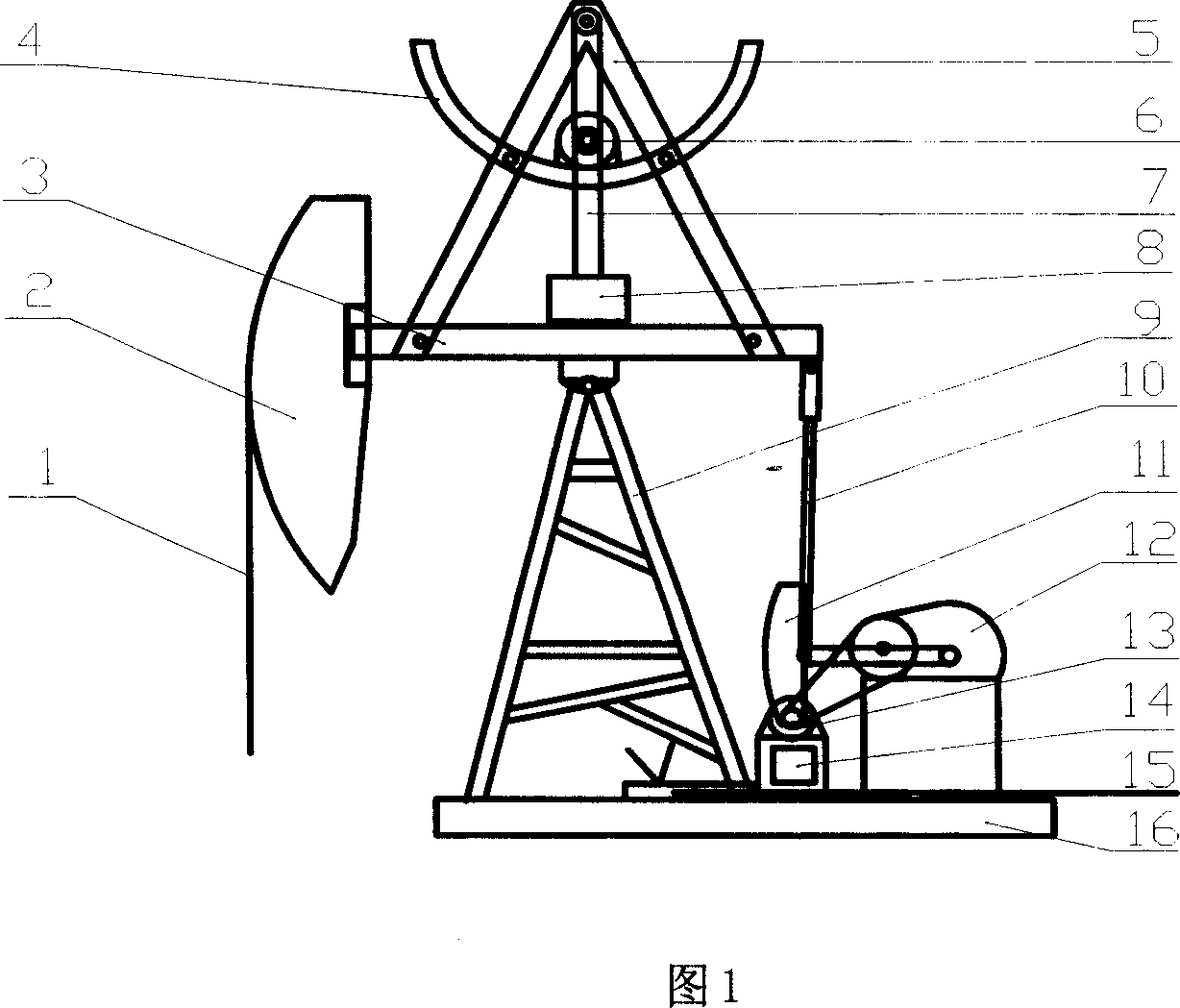

[0008] As shown in Fig. 1, the present invention comprises rope hanger 1, donkey head 2, beam 3, rack guide rail 4, single pendulum support 5, motor 6, swing bar 7, balance weight 8, support 9, connecting rod 10, Crank 11, speed reducer 12, motor 13, controller 14, braking device 15, base 16.

[0009] The present invention is obtained by transforming the conventional post-mounted beam pumping unit. A single pendulum device is added to the upper end of the beam. The motor 6 can reciprocate along the rack guide rail 4 to drive the balance weight 8 to swing back and forth.

[0010] During the downstroke, the balance weight 8 swings to the right end (facing the drawing) gradually, so that an extra load can be applied to the motor 13, thereby preventing the donkey head 2 from doing work on the motor 13. When the suspension point of donkey head 2 is at the bottom dead center, the balance weight 8 swings to the far right, so that the moment produced by the balance weight 8 is the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com