Inspection machine

A technology for a detector and a detection container, which is applied in the field of detectors, can solve problems such as time-consuming and labor-intensive modification work, and achieve the effect of simplifying the structure cost and reliable cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

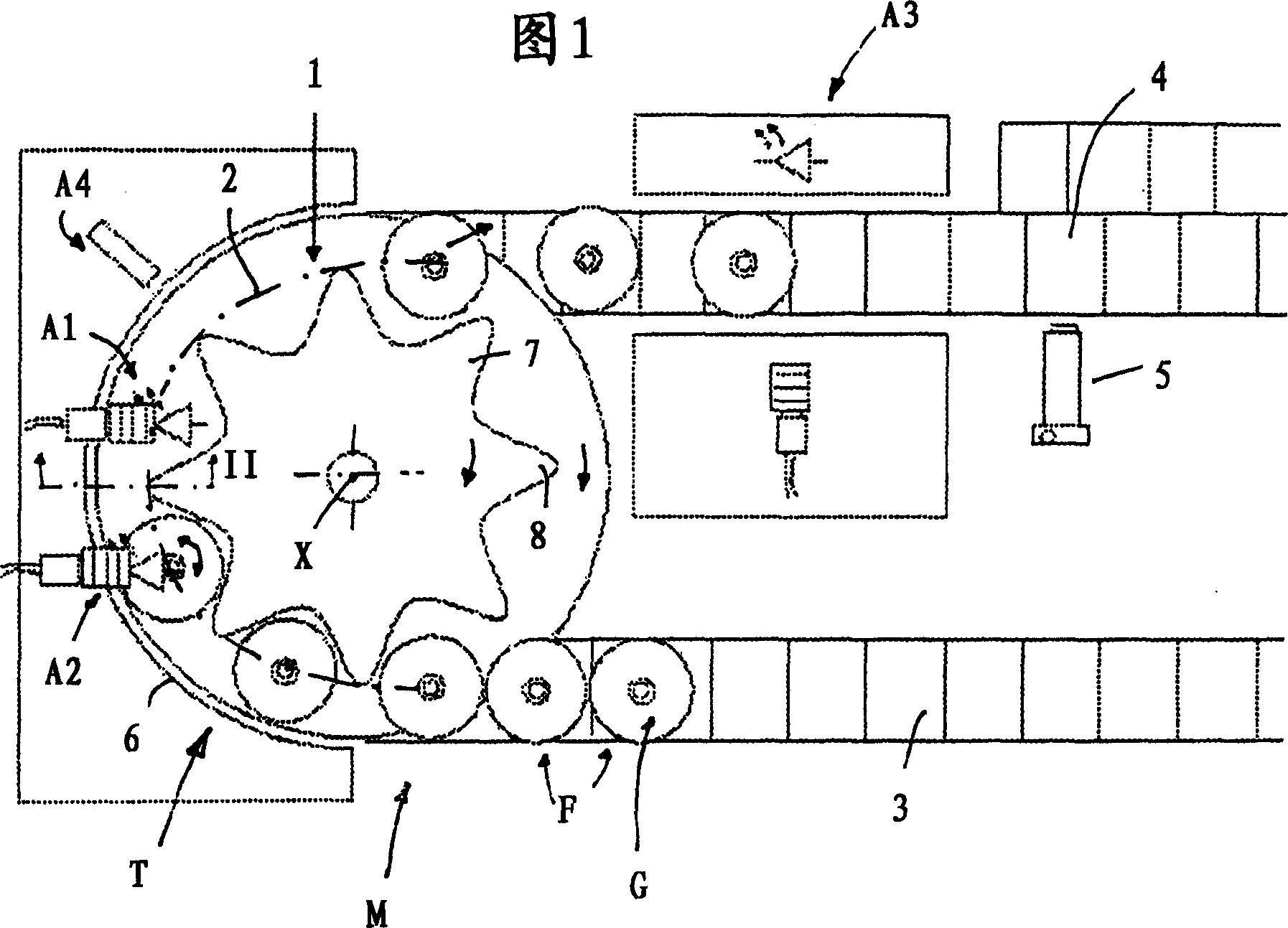

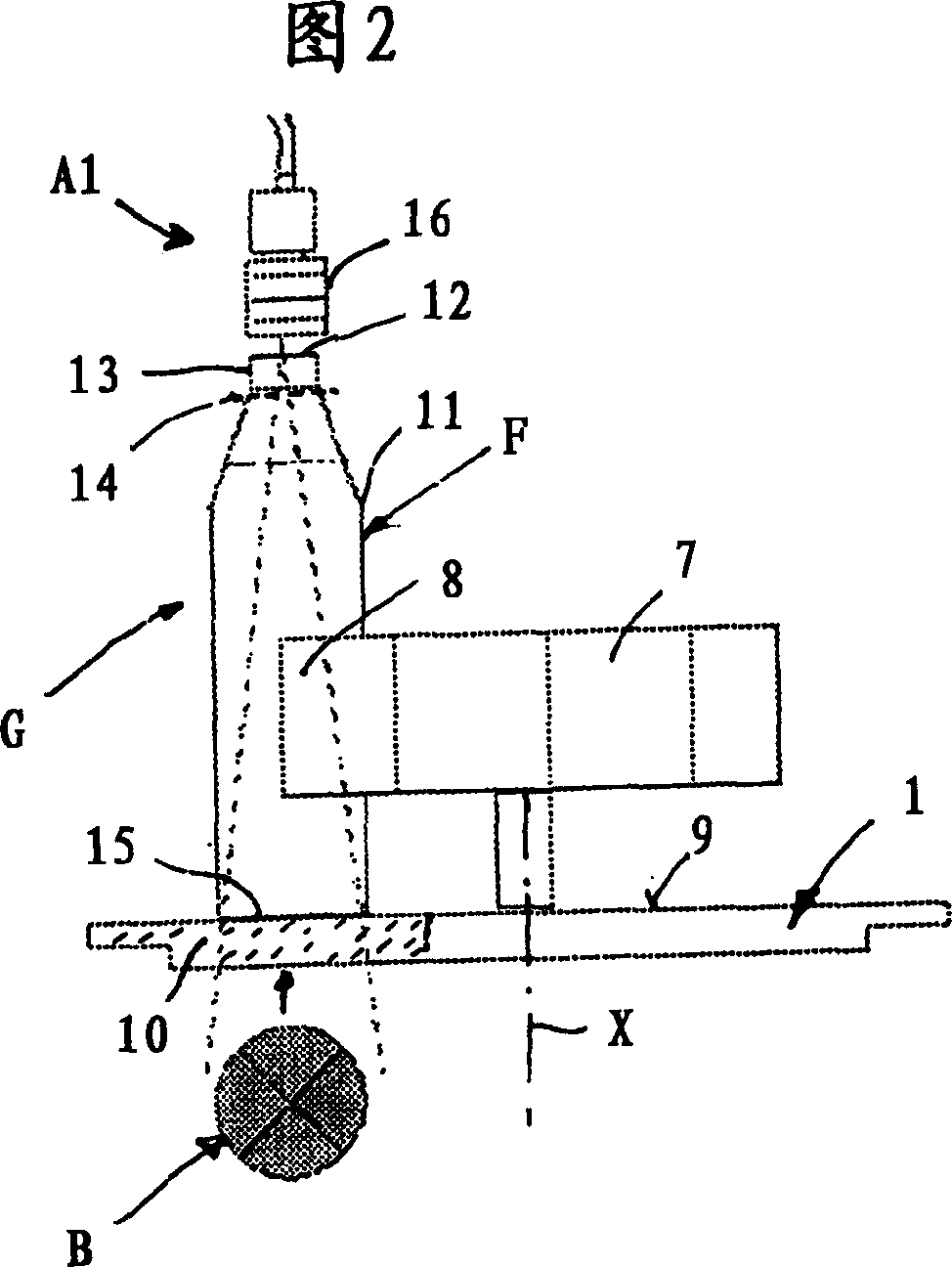

[0027] A detector M, shown in schematic top view in FIG. 1 , is used to inspect containers G, in particular bottles F, for example made of glass or plastic (PET), for damage and / or soiling. The detector comprises a transport device T by means of which the containers G are transported and detected continuously or intermittently on a semicircle spanning approximately 180°. In a simple embodiment of the detector M (not shown), the transport means T consists only of a substantially circular disc 1 drivable in rotation about the axis X, on the upper surface 9 of the disc ( FIG. 2 ). Containers G spaced apart from one another are transported vertically along an arcuate path 2 next to at least one inspection device A1 , A2 , A4 placed above the disc and inspected. The discs 1 carry the containers and are spaced from each other by gravity and friction. The containers are delivered by means of an input device 3, for example one after the other, onto the disc 1, and from the disc throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com