Shaft cool electric machine

A technology of motor shaft and motor casing, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of unsatisfactory heat dissipation effect, affecting motor heat dissipation, and difficulty in dissipating motor heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

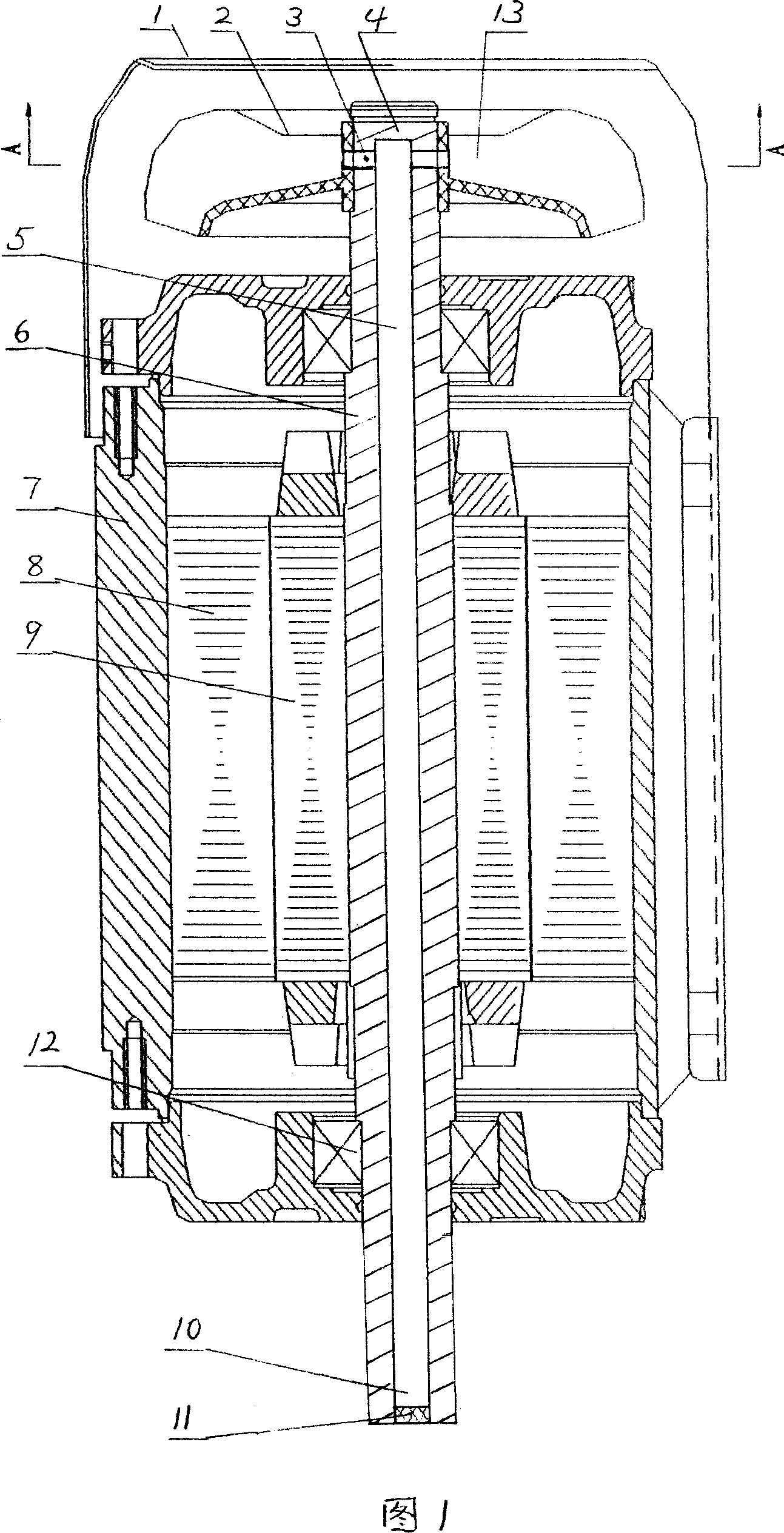

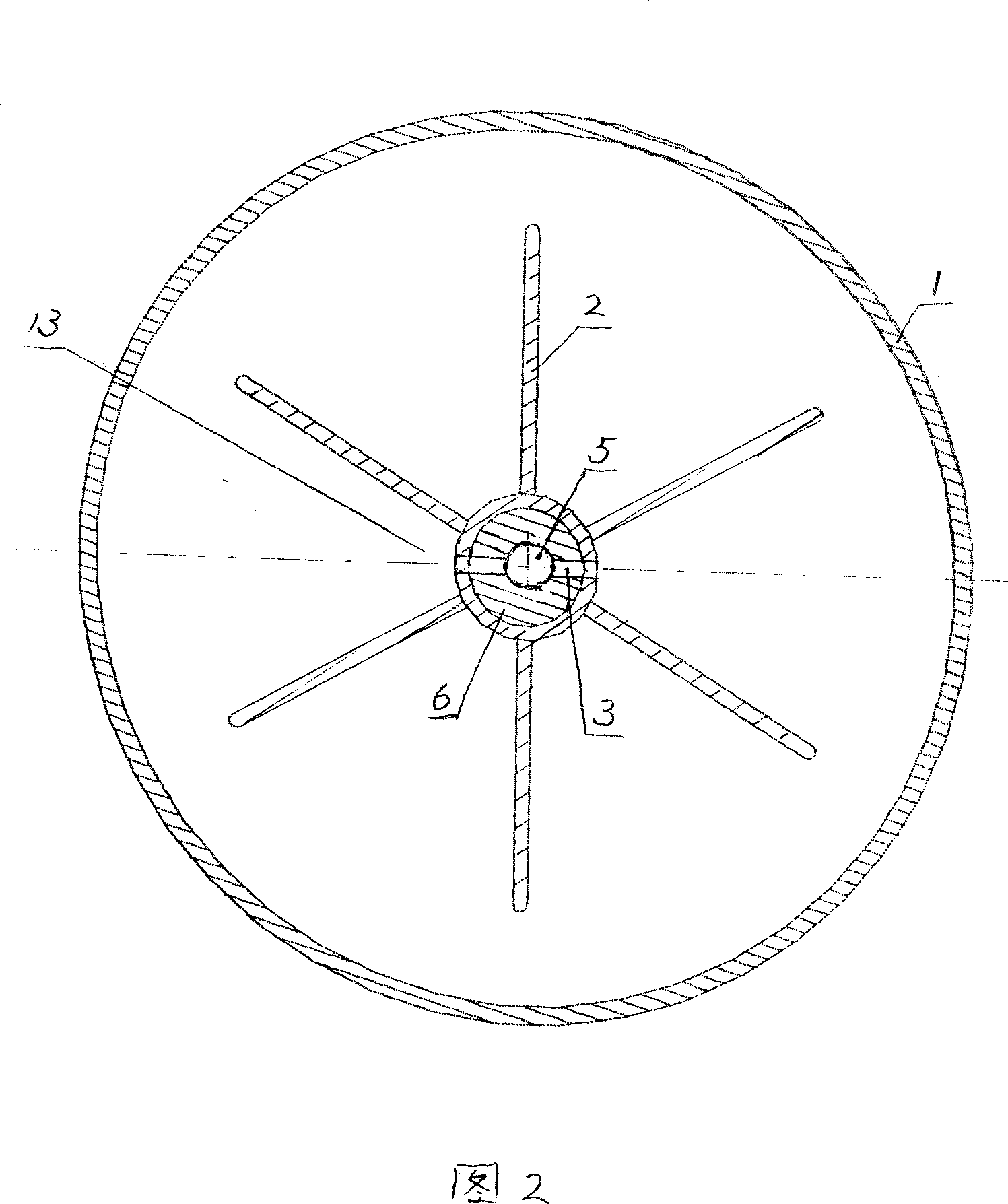

[0009] As shown in the figure, the shaft-cooled motor includes: a motor casing 7, a spindle 8, a rotor 9, a bearing 12, a fan blade 2, a hollow motor shaft 6, a wind cover 1, and a filter screen 11.

[0010] A hollow part 5 is provided inside the motor shaft to form a hollow motor shaft 6. The hollow part 5 at one end of the motor shaft 6 at one end of the fan blade 2 is sealed to become a sealed end 4, and the hollow part at the other end of the motor shaft 6 is a hollow end 10. The fixed place with the motor shaft 6 is provided with one or more through holes 3. In this embodiment, there are two through holes 3. The through holes 3 communicate with the hollow part 5 of the motor shaft 6 and the air guide space 13 of the fan blade 2. The air guide space 13 is located between the fan blades 2, the hollow part 5 is used to pass through the through hole 3 and the hollow end 10; the hollow end 10 of the motor shaft 6 is provided with a filter screen 11; the sealing end 4 of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com