High-frequency pole-free lamp

An electrodeless lamp, high-frequency technology, applied in discharge lamps, gas discharge lamp parts, lighting devices, etc., can solve problems such as damage, embrittlement of magnetic cores and coils, low efficiency, etc., achieve magnetic field stability, and improve heat dissipation efficiency. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

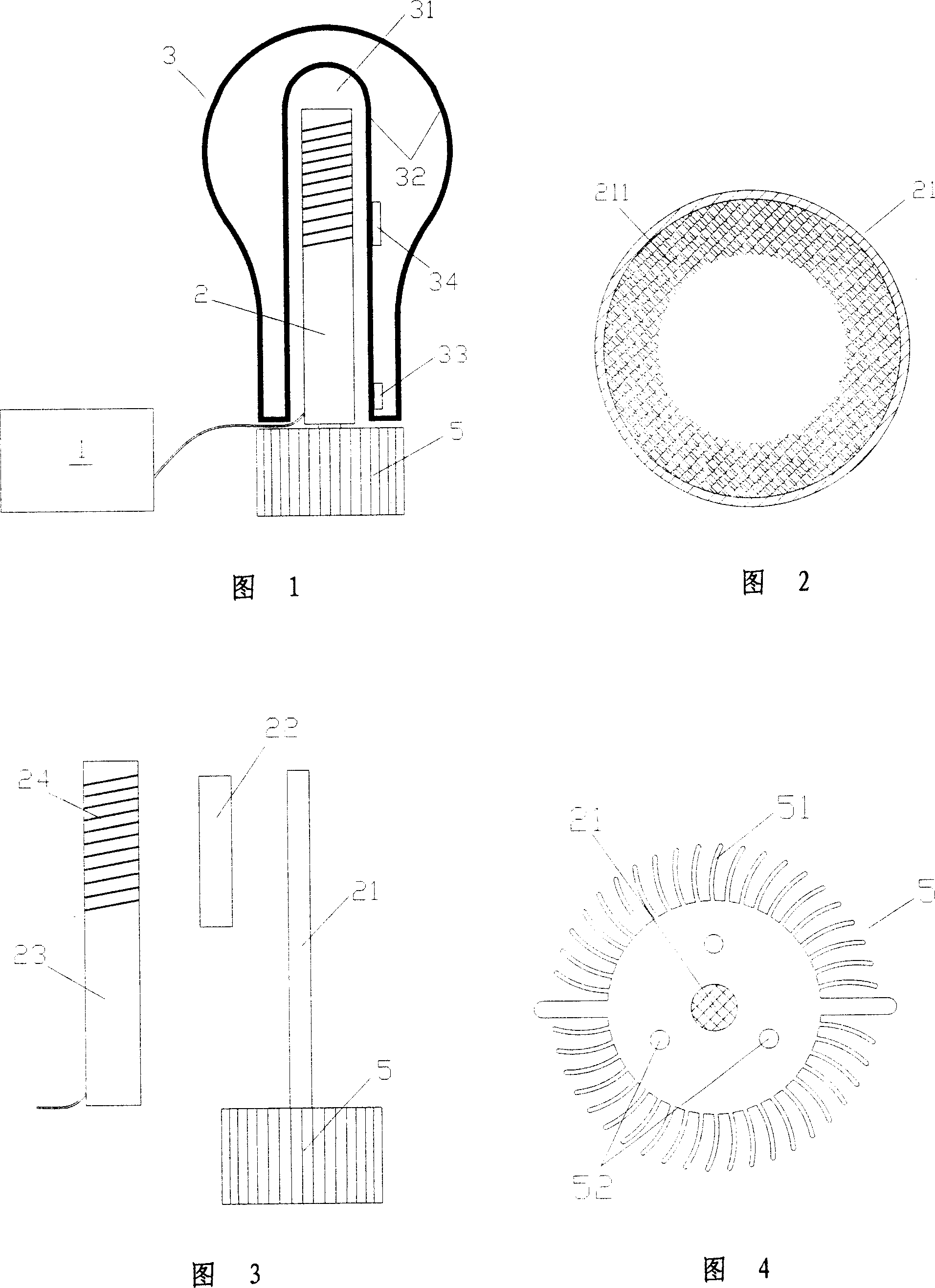

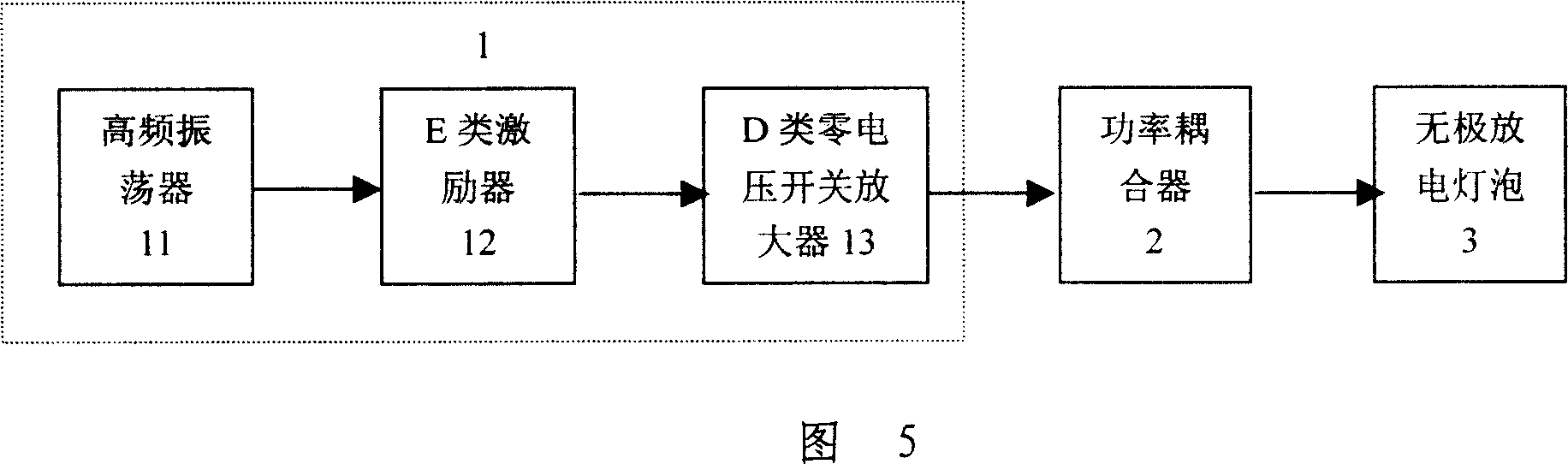

[0015] As shown in FIG. 1 , the high-frequency electrodeless lamp of the present invention includes: a high-frequency electron source 1 , a power coupler 2 , an electrodeless discharge bulb 3 and a cooling block 5 . The electrodeless discharge bulb 3 airtightly seals a discharge cavity whose inner wall is coated with rare earth three primary color phosphors 32, and the closed discharge cavity is filled with amalgam low-pressure mixed gas, and is equipped with a main amalgam 33 and an auxiliary amalgam 34 etc.; the center of the bottom of the electrodeless discharge bulb 3 is recessed inwardly to form a cylindrical recess 31, and the power coupler 2 is placed in the cylindrical recess 31. As shown in Figure 3, the power coupler 2 includes an insulating sleeve 23 made of high temperature resistant insulating material, an induction coil 24 wound outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com