Inner die forming anti-fogery method

A technology of in-mold forming and mold forming, which is applied in the direction of coating, etc., can solve the problems of high printing cost, not vivid enough colors and patterns, and poor aesthetic feeling, and achieve the effect of preventing counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to fully understand the present invention, it is explained as follows according to the accompanying drawings:

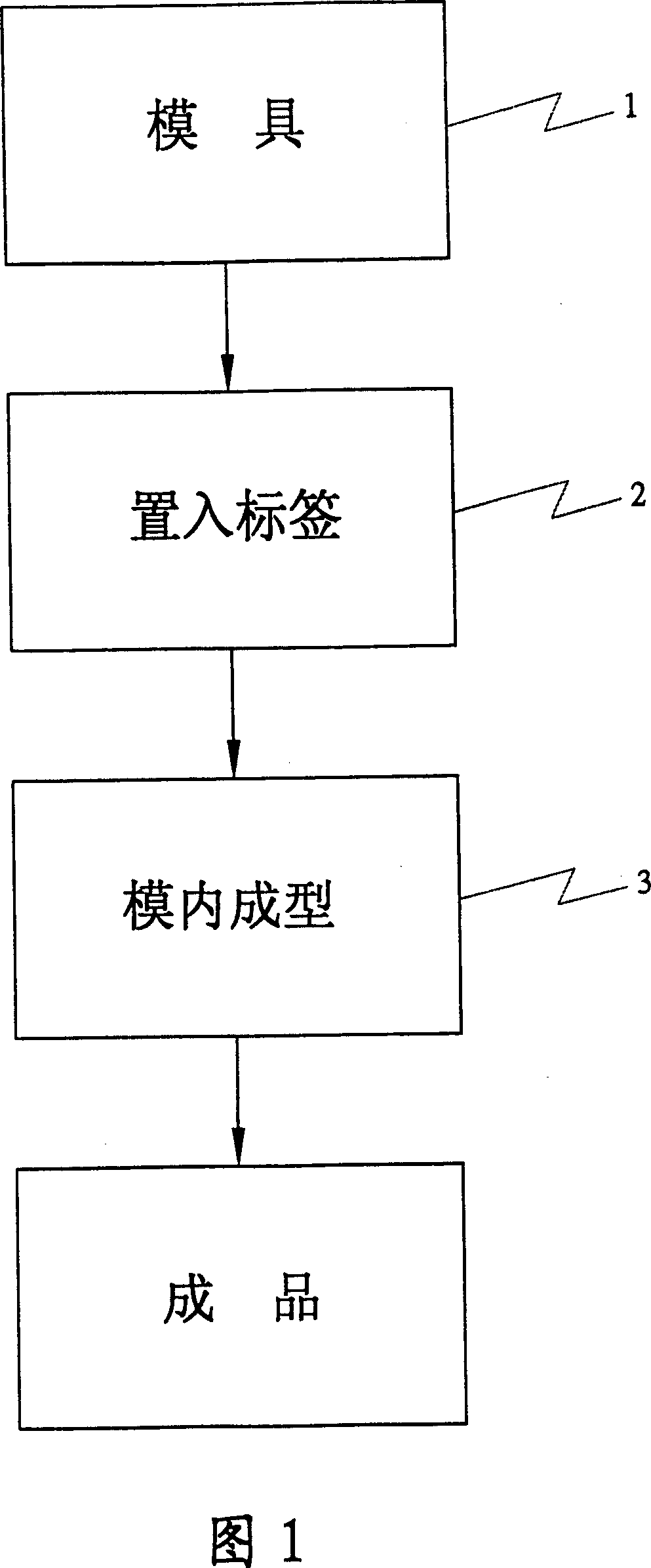

[0026] As shown in Figures 1 to 4, it is the in-mold forming anti-counterfeiting method of the present invention, and the present invention includes:

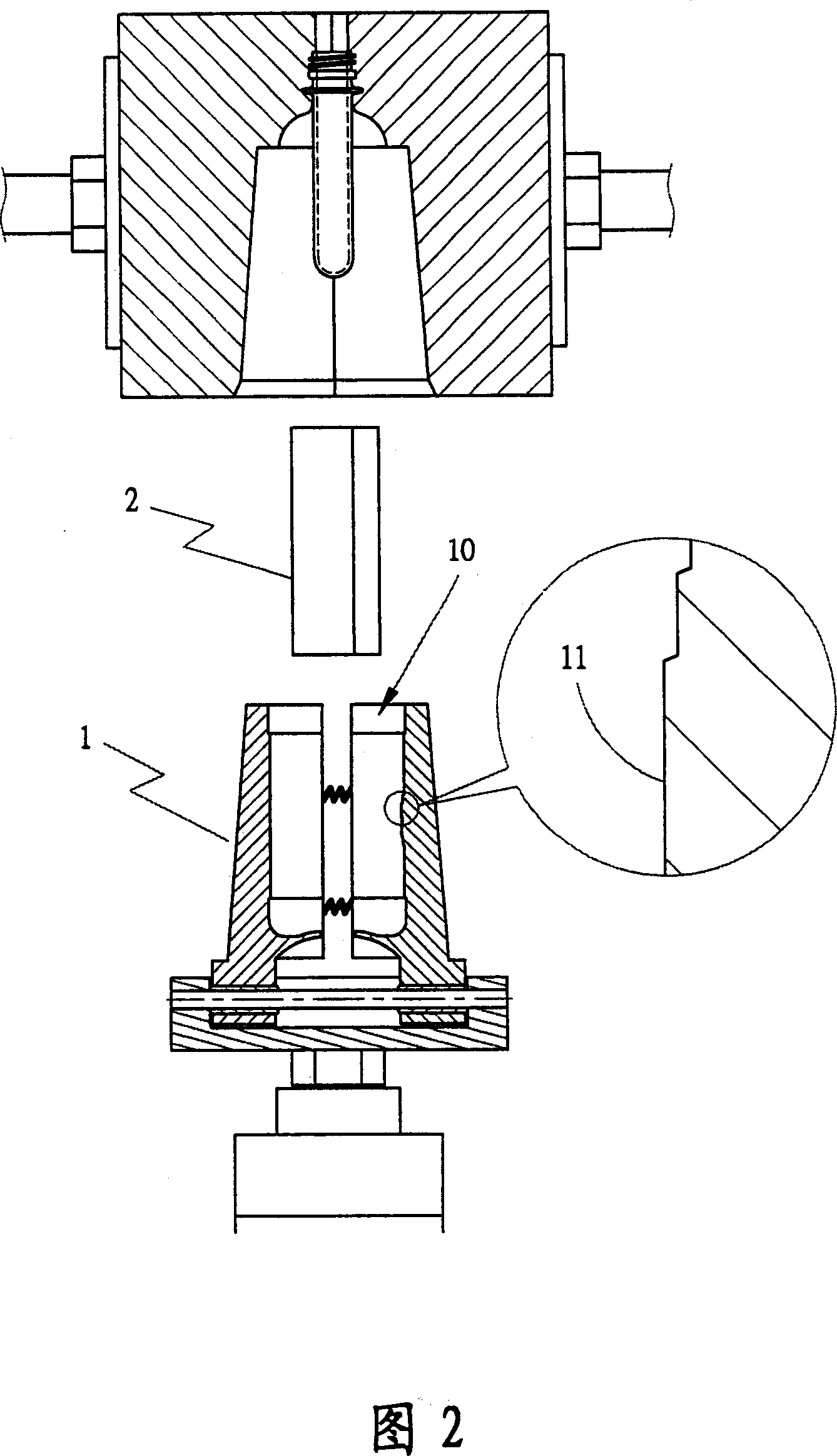

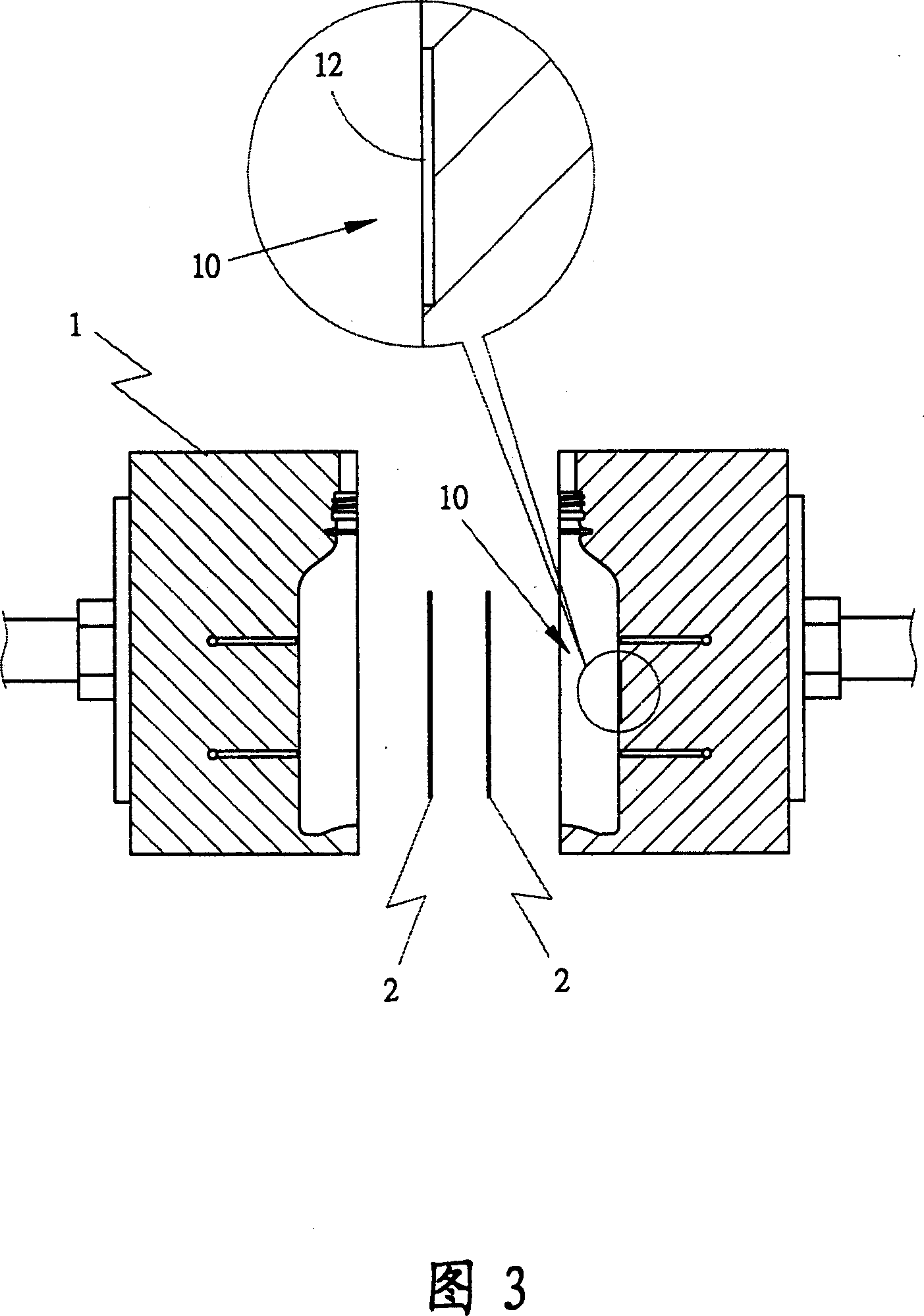

[0027] Mold 1, mold 1 molding mold cavity 10 and pre-set with single (or multiple) convex portion 11 (as shown in Figure 2), or concave portion 12 (as shown in Figure 3), or be concave-convex portion 13 (as shown in Figure 3) simultaneously 4), are all applicable embodiments of the present invention, the above-mentioned convex portion 11 or concave portion 12, or concave-convex portion 13 can be designed as any figure, or text, or totem, and when the label is in-molded, the above-mentioned figure , or text, or totem appears on the label of the molded product.

[0028] Inserting the label 2, inserting the label 2 is to put the label 2 with special elasticity or toughness into the mold, when the label 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com