Rope fastener injecting method

A rope buckle and rope technology, which is applied in the field of rope buckle injection molding, can solve problems such as lowering selling points, affecting product appearance quality, and rope head falling out, so as to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

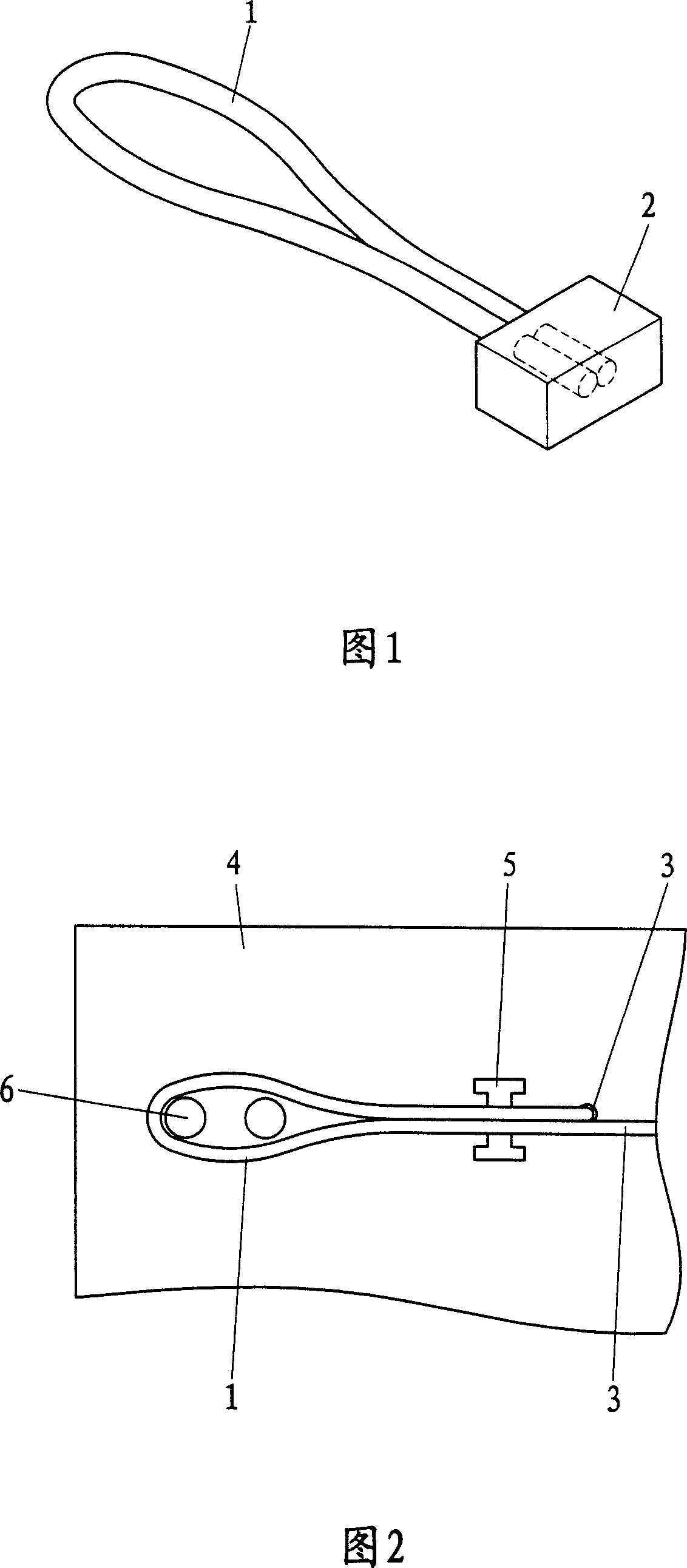

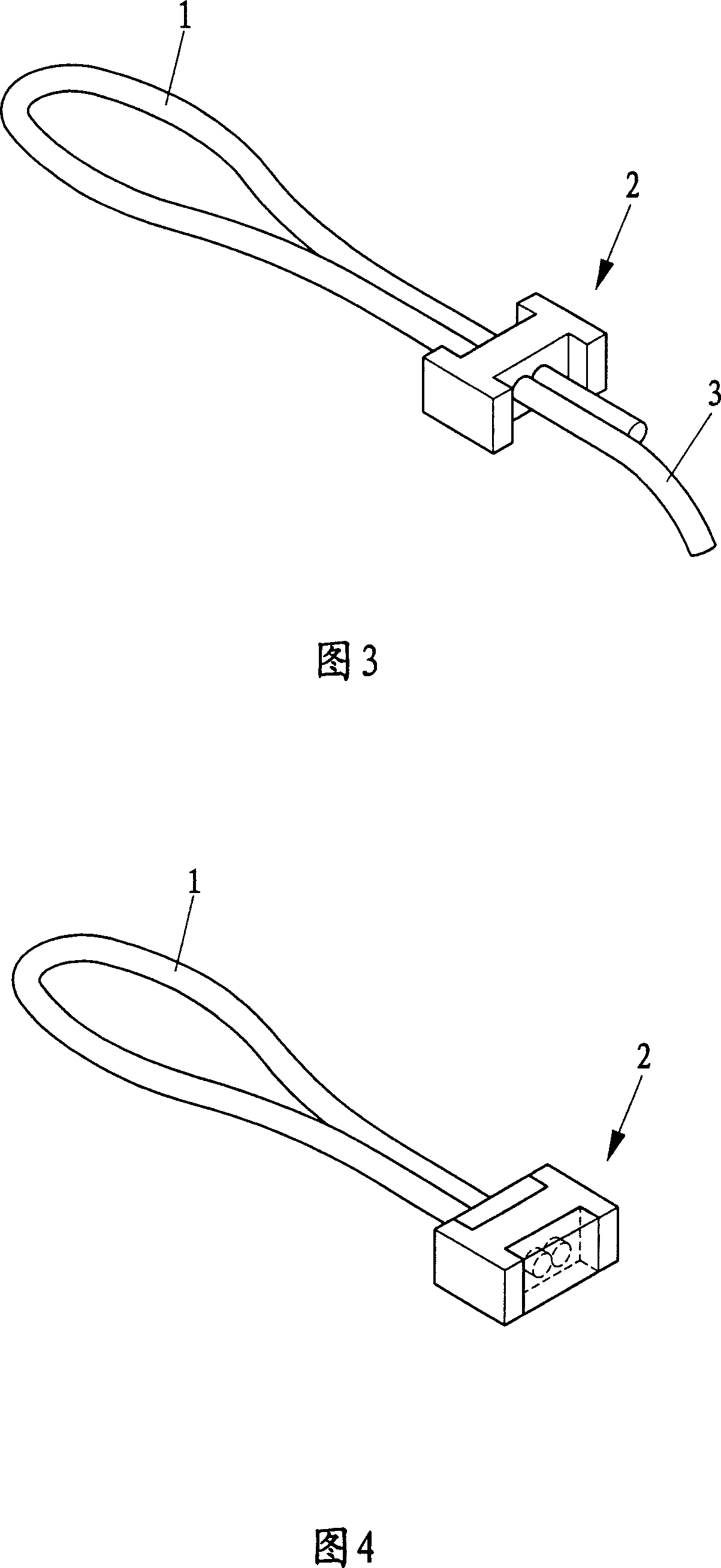

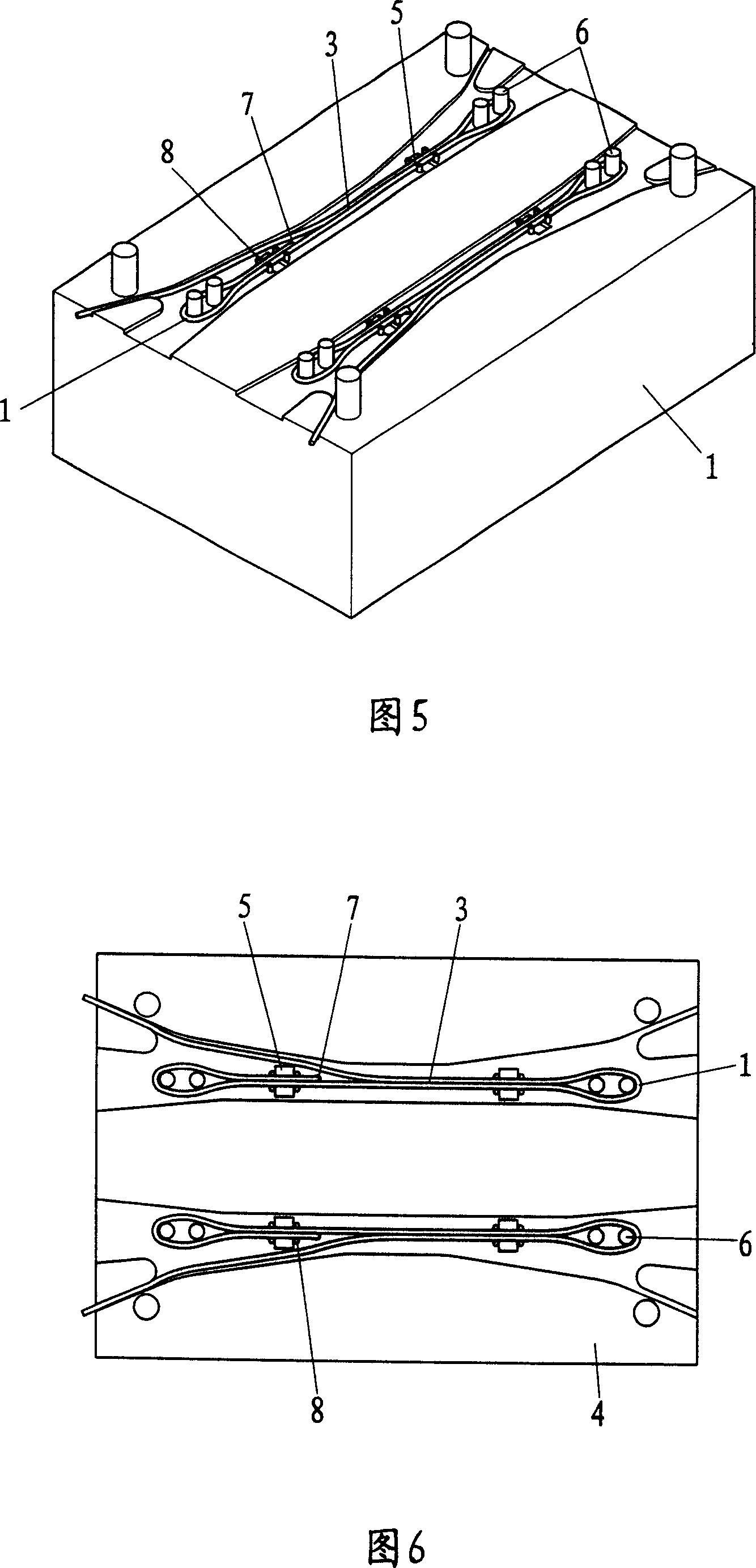

[0022] As shown in Figure 2, the injection molding method of the rope buckle of the present invention is as follows: one end of the rope 3 is fixed in the cavity 5 of the fixed mold 4, and then the rope 3 is crossed over the cavity 5 and looped around the cavity. On the positioning post 6 on the other side of the cavity 5 to form a rope cover 1, the positioning post 6 plays a fast, stable and accurate fixing role, and then the other end of the rope 3 bypassing the positioning post 6 crosses the cavity again in reverse 5, and tighten the other end of the rope 3 with a tensioning mechanism, so as to keep the whole rope 3 in a tensioned state, after that, inject the buckle head 2 with injection molding technology, and place the rope part across the cavity 5 Wrap it in the buckle head 2, and finally, take the injection-molded semi-finished product (as shown in Figure 3) out of the mold, and cut off the rope exposing the rear end of the buckle head 2 to become a finished rope buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com