Vehicle body structure of vehicle

A body and vehicle technology, applied in the direction of upper structure, vehicle parts, upper structure sub-assembly, etc., can solve problems such as body deformation, achieve the effect of improving torsional rigidity and strengthening the side wall of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

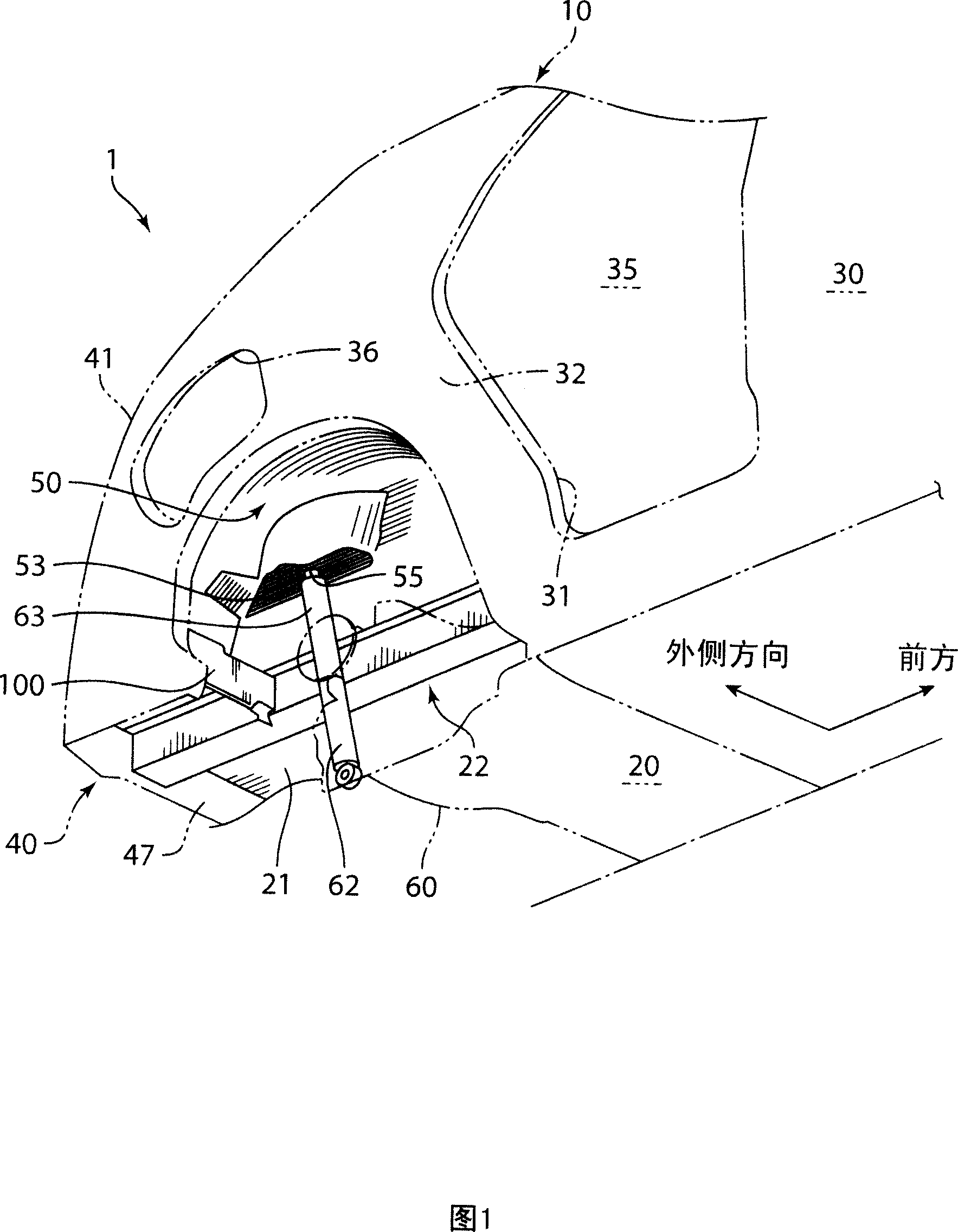

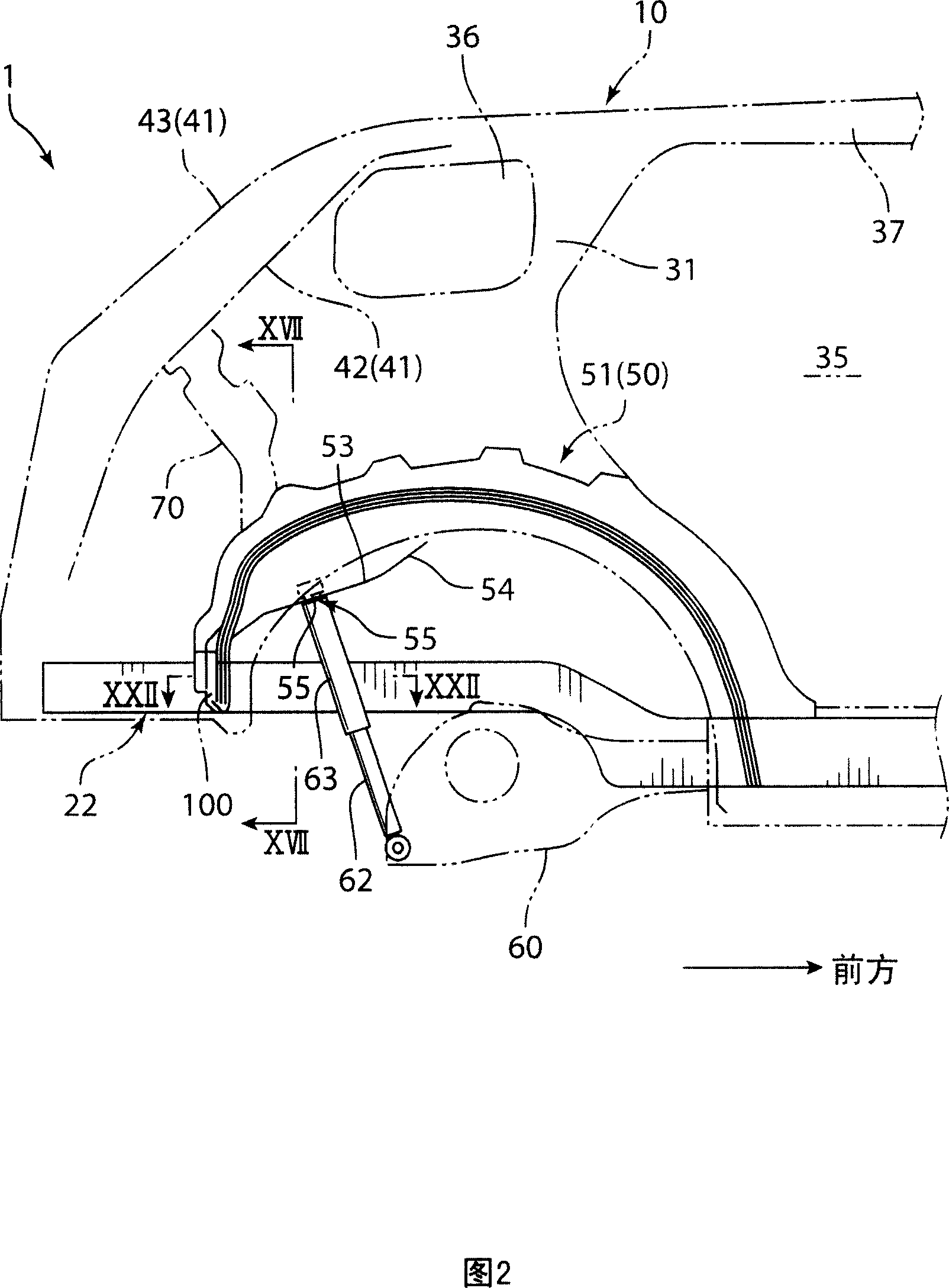

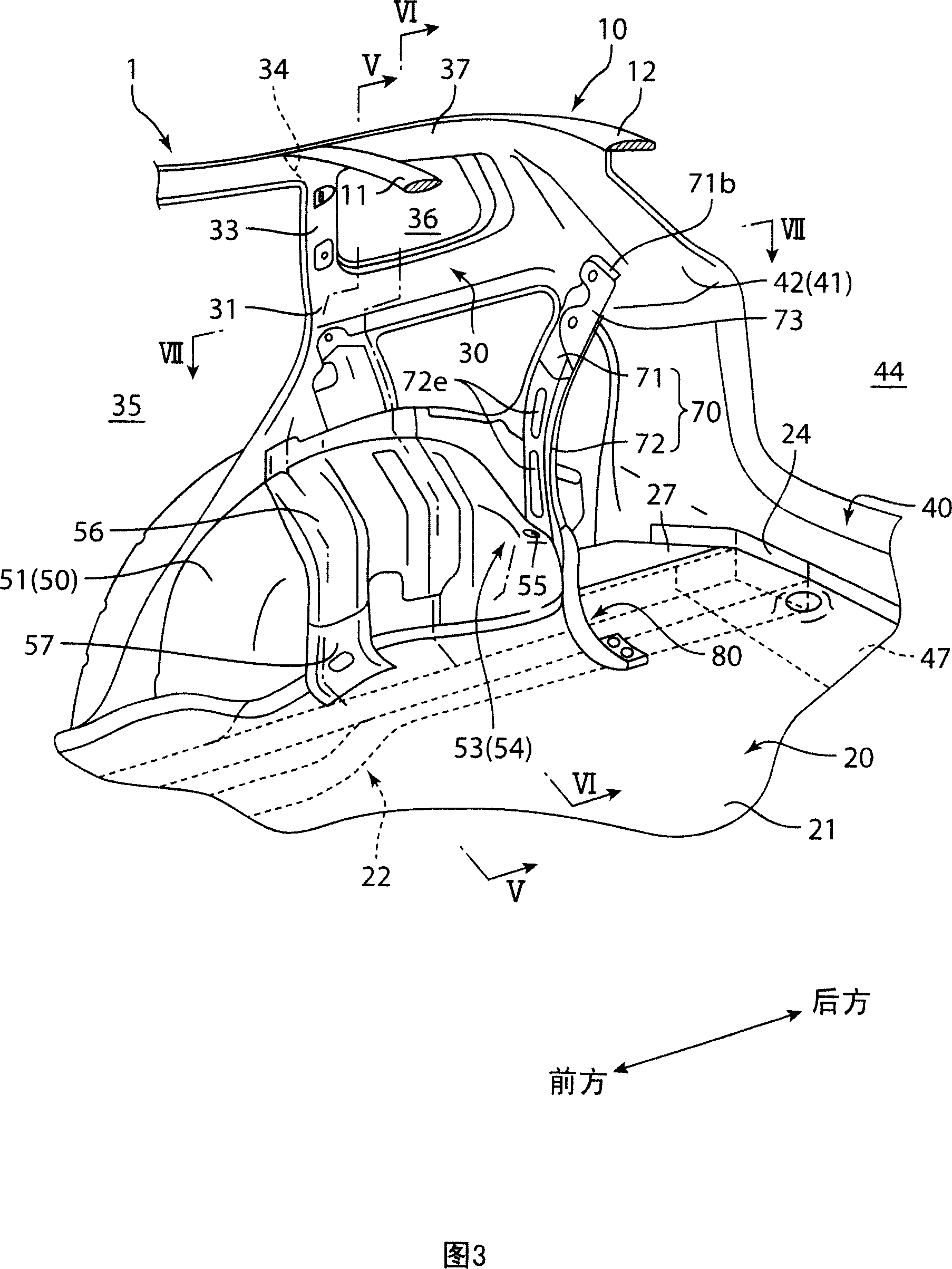

[0065] First, a first embodiment will be described with reference to FIGS. 1 to 24 . In the following description, FIGS. 1 to 24 show only the right side of the vehicle 1, but the left side of the vehicle 1 also has the same structure.

[0066] Referring to FIGS. 1 to 3 , the vehicle 1 according to the first embodiment is a vehicle such as a single box car, which has a roof 10 constituting the roof of the vehicle compartment; an underbody 20 constituting the floor of the compartment; Between the roof 10 and the underbody 20, a side wall 30 constituting the side of the vehicle body; between the roof 10 and the underbody 20, a rear wall 40 constituting the rear of the vehicle; formed on the underbody 20 Between the vehicle body side wall portion 30 is a wheel house 50 for accommodating rear wheels (not shown).

[0067] The roof 10 includes roof reinforcement members 11 and 12 arranged front and rear and extending in the vehicle width direction (see FIG. 3 ). The roof reinforceme...

no. 2 approach

[0151] Next, a second embodiment will be described. However, in each of the following embodiments, the same components as those in the first embodiment are given the same reference numerals, and description thereof will be omitted.

[0152] Referring to FIGS. 25 and 26 , in the second embodiment shown in the figures, a member independent of the main floor 21 , that is, a bottom reinforcement member 28 is provided at the upper end of the rear side member 22 .

[0153] Referring to FIG. 27 at the same time, the bottom reinforcement member 28 is a substantially rectangular plate-shaped member, and its thickness is about twice (1.0 mm) that of the main base plate 21 (for example, 0.5 mm). The outer side of the bottom reinforcement member 28 in the vehicle width direction has a flange 28 a formed along the contour of the lower end portion of the wheel house inner 51 . As shown in FIG. 27, the flange 28a extends along the lower end contour of the wheel house inner member 51 in a pa...

no. 3 approach

[0161] Fig. 28 relating to the third embodiment is a side view showing the rear part of the vehicle body provided with the seat belt. In this FIG. 28 , a portion of the inner panel 31 located at the periphery of the rear window opening 36 is removed (part B of FIG. 28 ).

[0162] Referring to FIG. 28 , the vehicle body side wall portion 30 of the vehicle 1 is provided with seat belts 150 respectively corresponding to the second row of seats and the third row of seats (both not shown), which can restrain the occupants seated in these seats. and 140.

[0163] The seat belt 140 for the third row of seats is equipped with a seat belt retractor (seat belt retractor) 141 for taking up and accommodating the seat belt 140 at one end thereof, and the seat belt retractor 141 is connected and fixed to the seat belt 140 by a fixing bolt 143. On the bracket part 73. On the other hand, the other end of the seat belt 140 is attached with a lower support member 145 such as an anchor plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com