Electrically driven camshaft adjuster

A technology of adjusting device and camshaft, applied in valve device, engine element, machine/engine, etc., to achieve the effect of simple structure and improved fail-safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

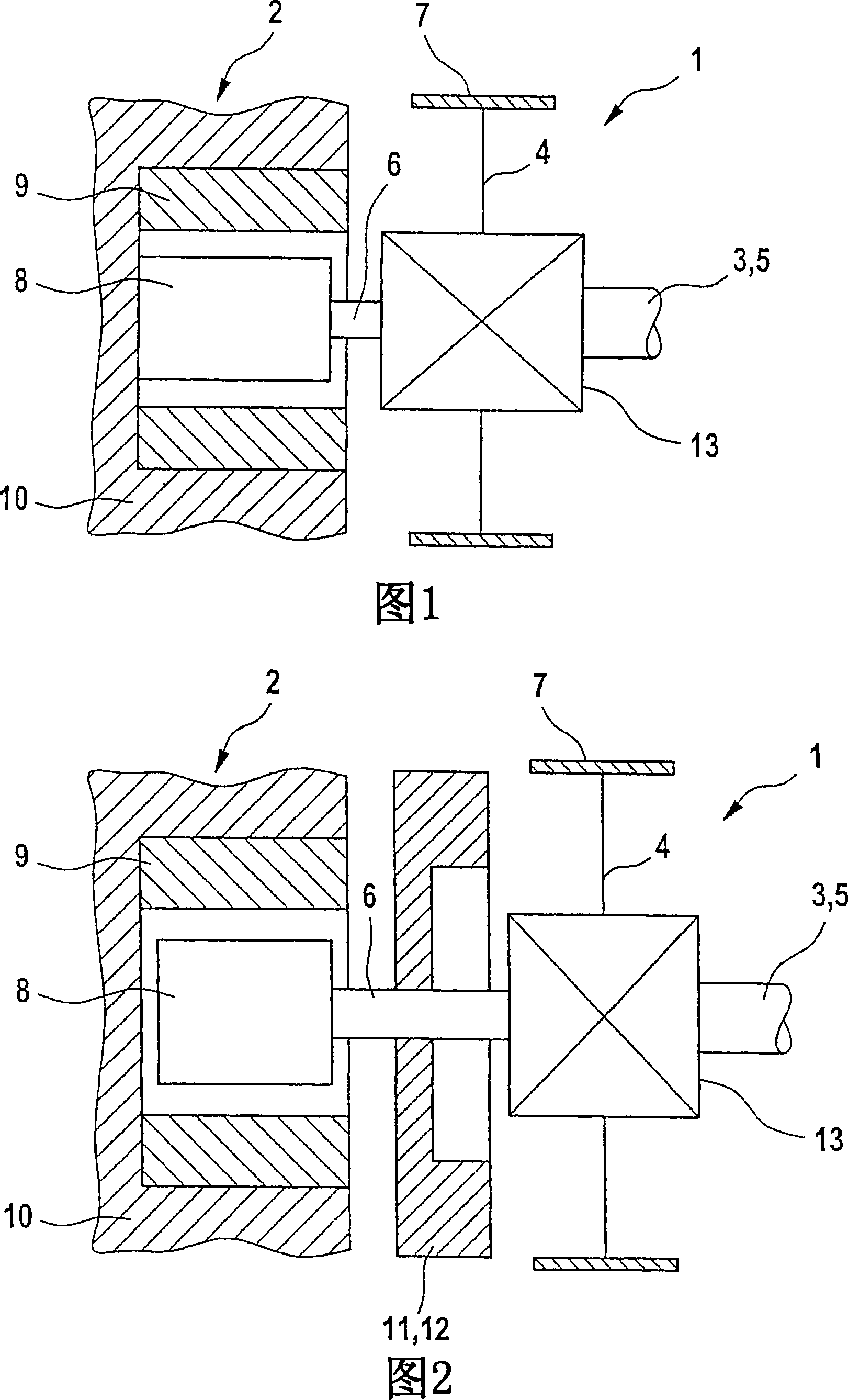

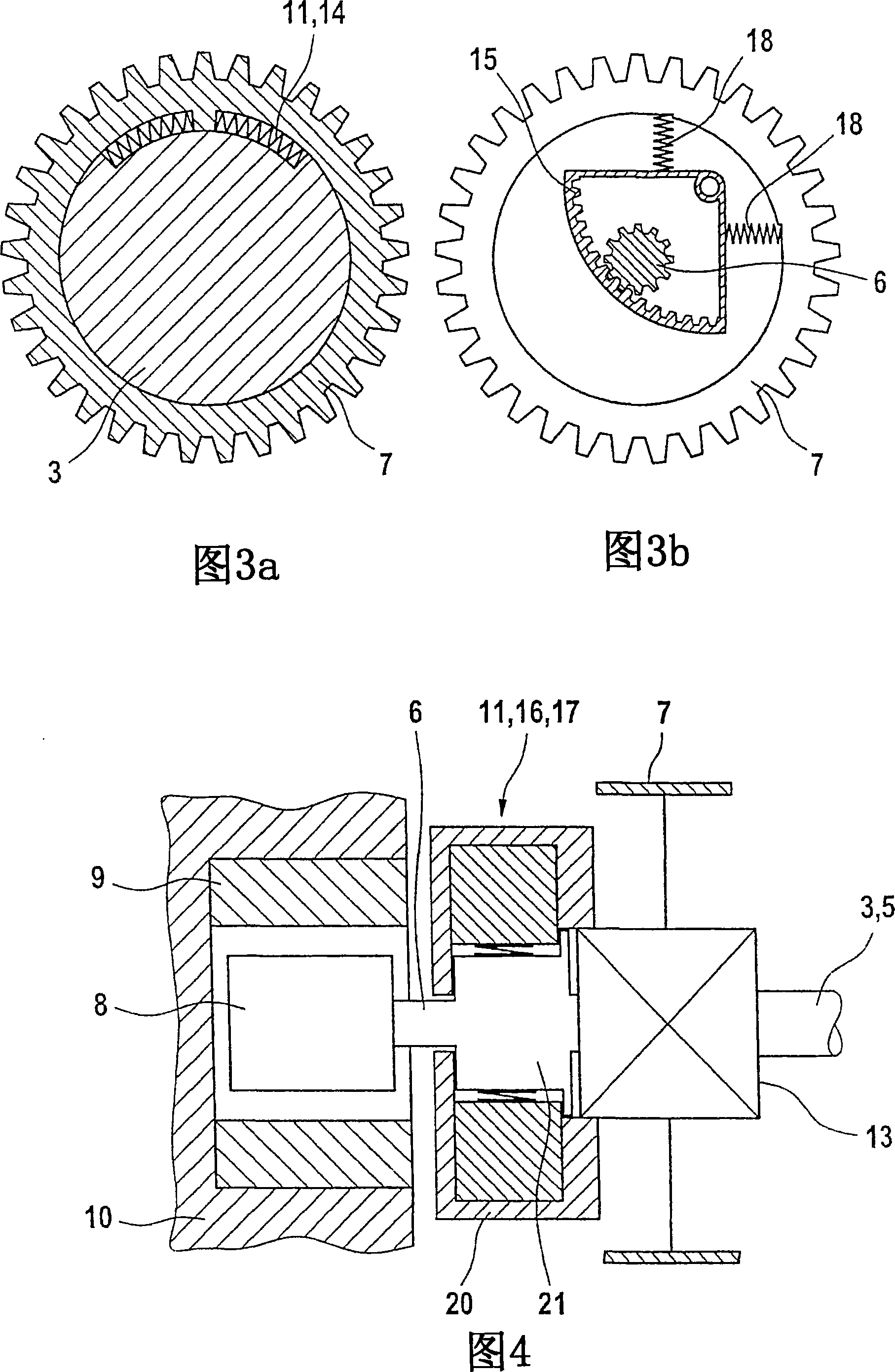

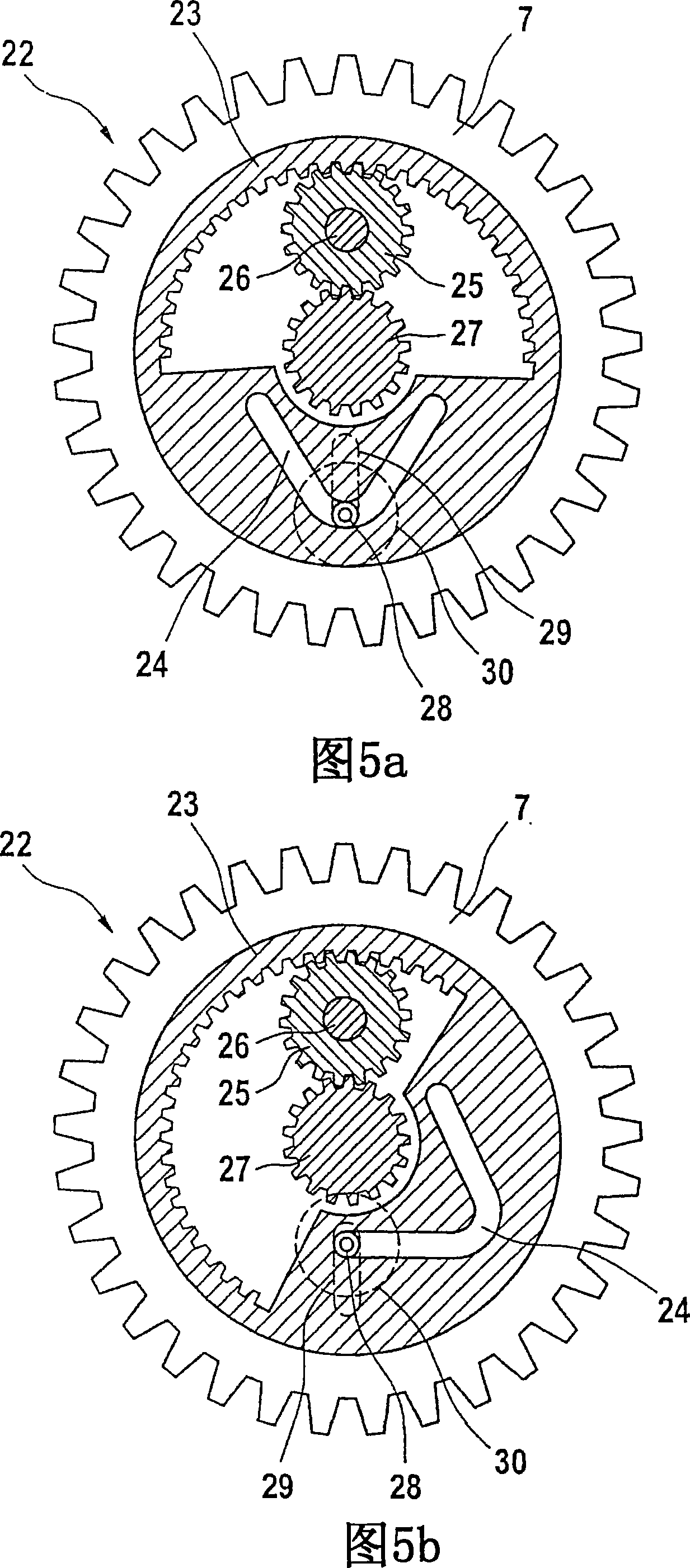

[0042] An embodiment of the invention is shown in FIG. 1 as an adjusting device with a variable-speed gearbox 13 and an adjusting motor 2 consisting essentially of a rotor 8 and a stator 9 . The adjusting device serves to adjust the angular position between the crankshaft and the camshaft 3 in an internal combustion engine (not shown). The transmission gearbox 13 is designed as a three-shaft transmission with a driving element 4 , a driven element 5 and an adjusting shaft 6 . The driving element 4 is fixedly connected with the drive wheel 7 and the crankshaft through an unshown gear, toothed belt or toothed chain. The driven part 5 is fixedly connected to the camshaft 3 and the adjusting shaft 6 to the rotor 8 of the adjusting motor 2 . The stator 9 of the adjusting motor 2 is fixedly connected to the cylinder head 10 and is at rest. Camshaft 3 has a reference position or emergency running position which must be reached for reliable starting and limited operation. Since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com