Front and back stagged double side insert plate back plate

A double-sided plug-in and backplane technology, which is used in the structural connection of printed circuits, devices for connecting/disconnecting components, and printed circuit components, etc., which can solve the problems of upside-down printing on the panel, inconvenient use and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

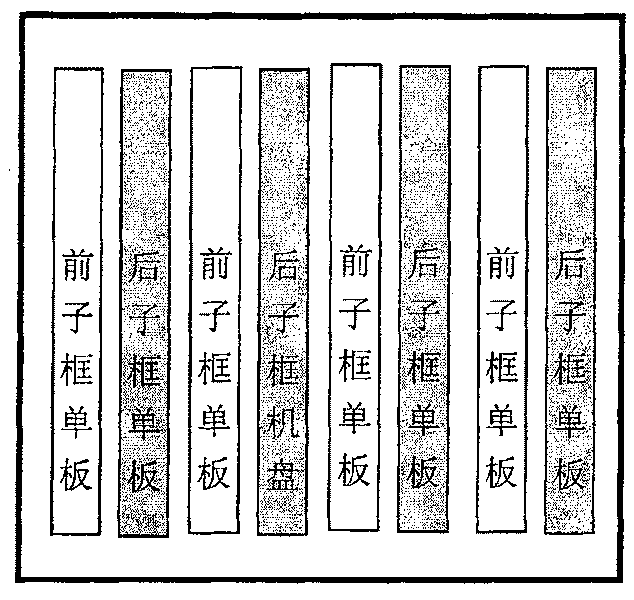

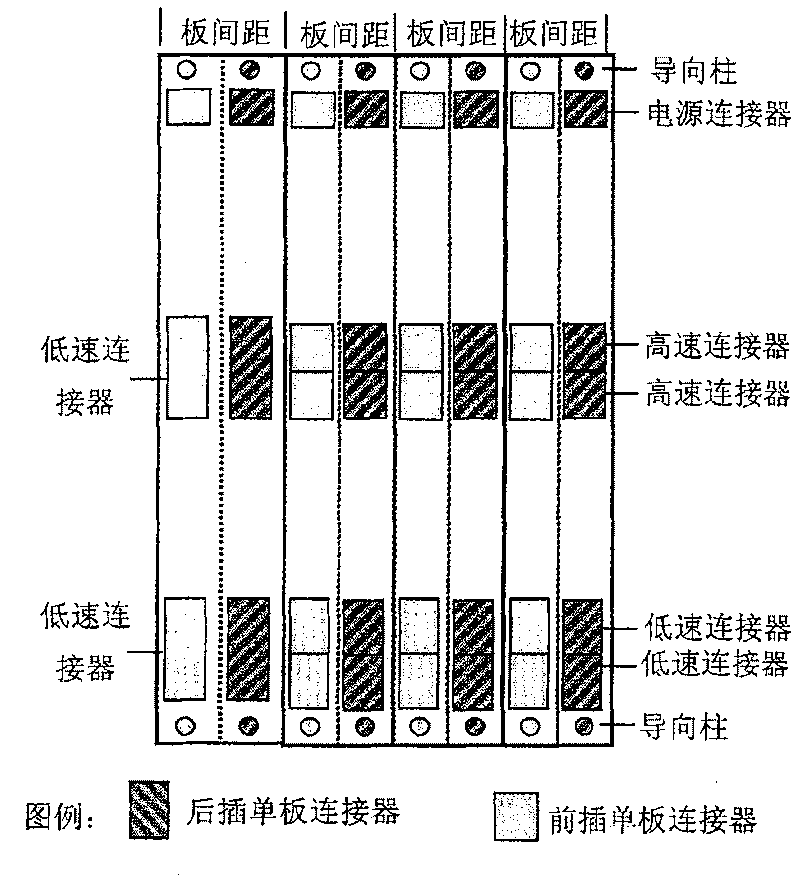

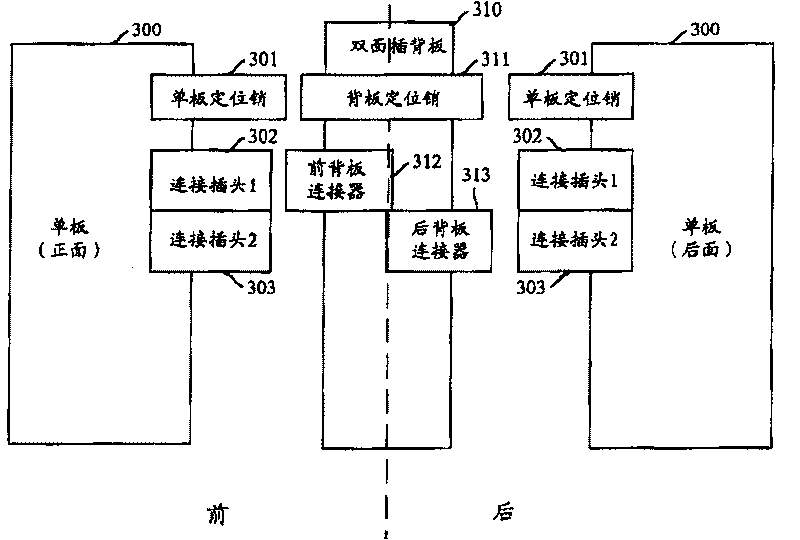

[0023] In the design of the equipment chassis, the front chassis and the rear chassis are staggered up and down by a certain height, and the front and rear chassis are not separated from each other in the horizontal direction, and are staggered by a certain height in the vertical direction. The front frame and the rear frame share the same PCB (printed circuit) backplane, and the front and back of the backplane are respectively equipped with a connector connected to the front board and a connector connected to the rear board. The position of the front board connector on the backplane is exactly the same as that of the rear board connector in the horizontal direction, and they are staggered up and down by a certain height in the vertical direction. The positions of the front board connectors and the rear board connectors on the backplane are completely staggered up and down and inserted into each other. The connectors on the backplane connected to the front board and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com