Synthetic resin pallet

A synthetic resin and tray technology, applied in packaging, containers with multiple items, transportation and packaging, etc., can solve problems such as hook damage, cutting, and inability to stack synthetic resin trays stably, to reduce storage space and stabilize The effect of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

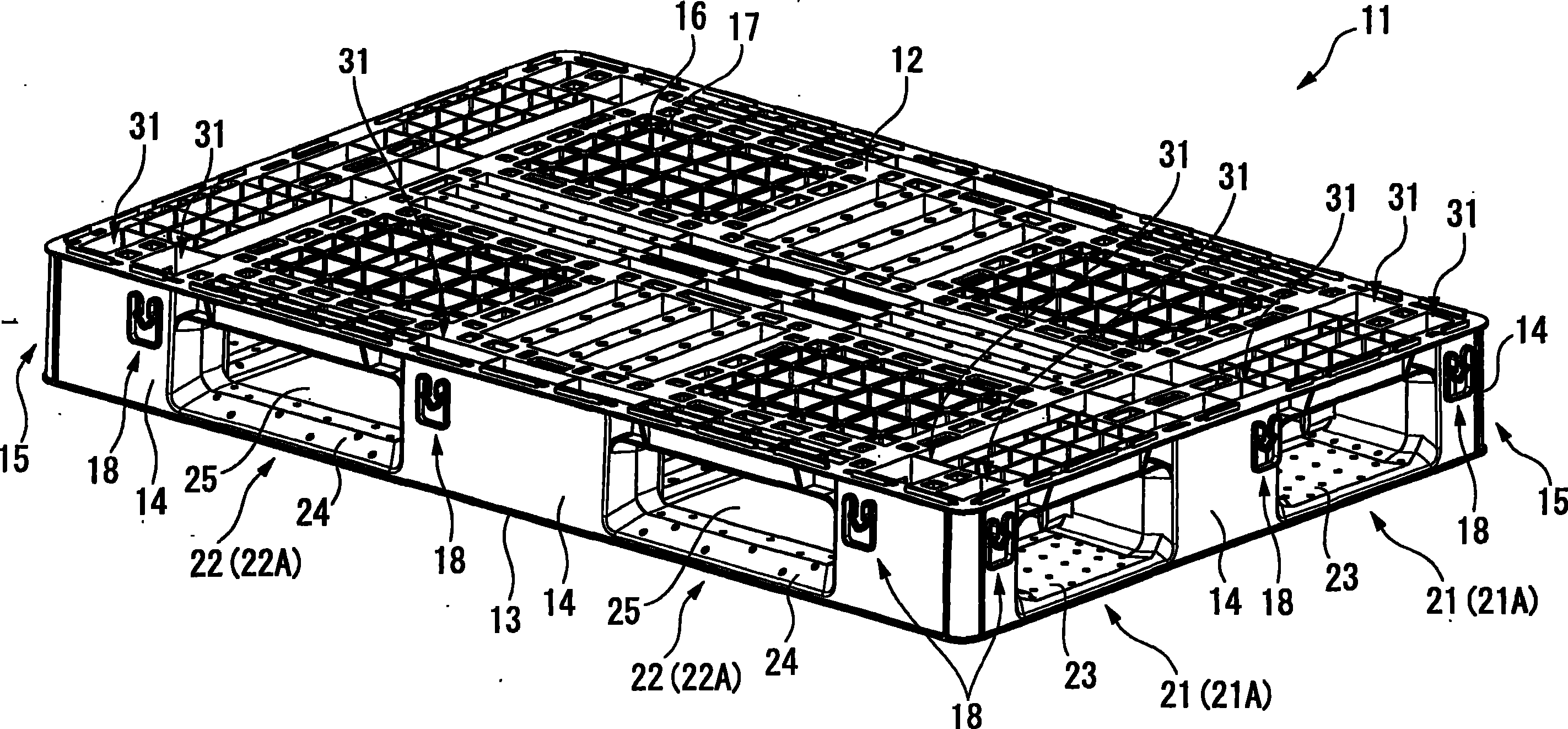

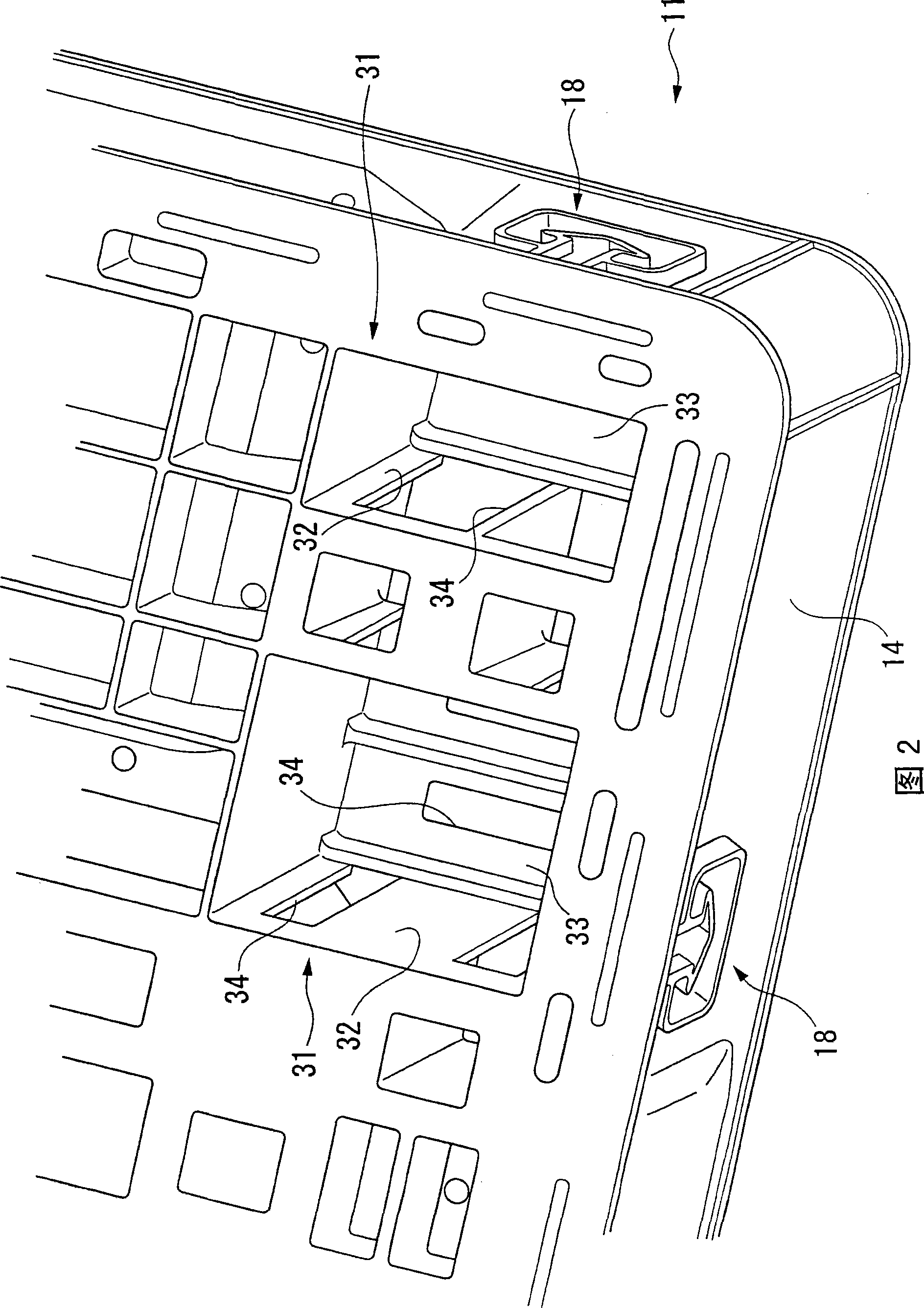

[0042] Hereinafter, a synthetic resin tray according to an embodiment of the present invention will be described with reference to the attached drawings.

[0043] 1 to 7 show a synthetic resin tray as an example of the present invention.

[0044] As shown in Figure 1, the synthetic resin tray is formed into a rectangular box shape as a whole, and has an upper panel-shaped portion 12 forming the upper surface of the synthetic resin tray 11, a lower panel-shaped portion 13 forming the lower surface, and connecting the upper panel-shaped portion 12 and The beam portion 14 of the lower plate portion 13 . As shown in FIGS. 1 and 4 , the upper plate-shaped portion 12 and the lower plate-shaped portion 13 are arranged substantially in parallel.

[0045] This synthetic resin tray 11 is made of, for example, olefin resins such as polyethylene or polypropylene, and the top-shaped member formed by integral molding of the upper panel-like part 12 and the beam part 14, and the lower panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com