Deflection correcting mechanism

A technology of deviation correction wheel and deviation correction device, which is applied in the field of deviation correction mechanism, and can solve the problems of inability to adjust the deviation correction force, affecting paper introduction and deviation correction, and reducing the friction coefficient of driving wheels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The deviation correcting mechanism of the present invention is installed on the paper transmission system, and is used to ensure that sheet media such as paper can be smoothly and unbiasedly transmitted.

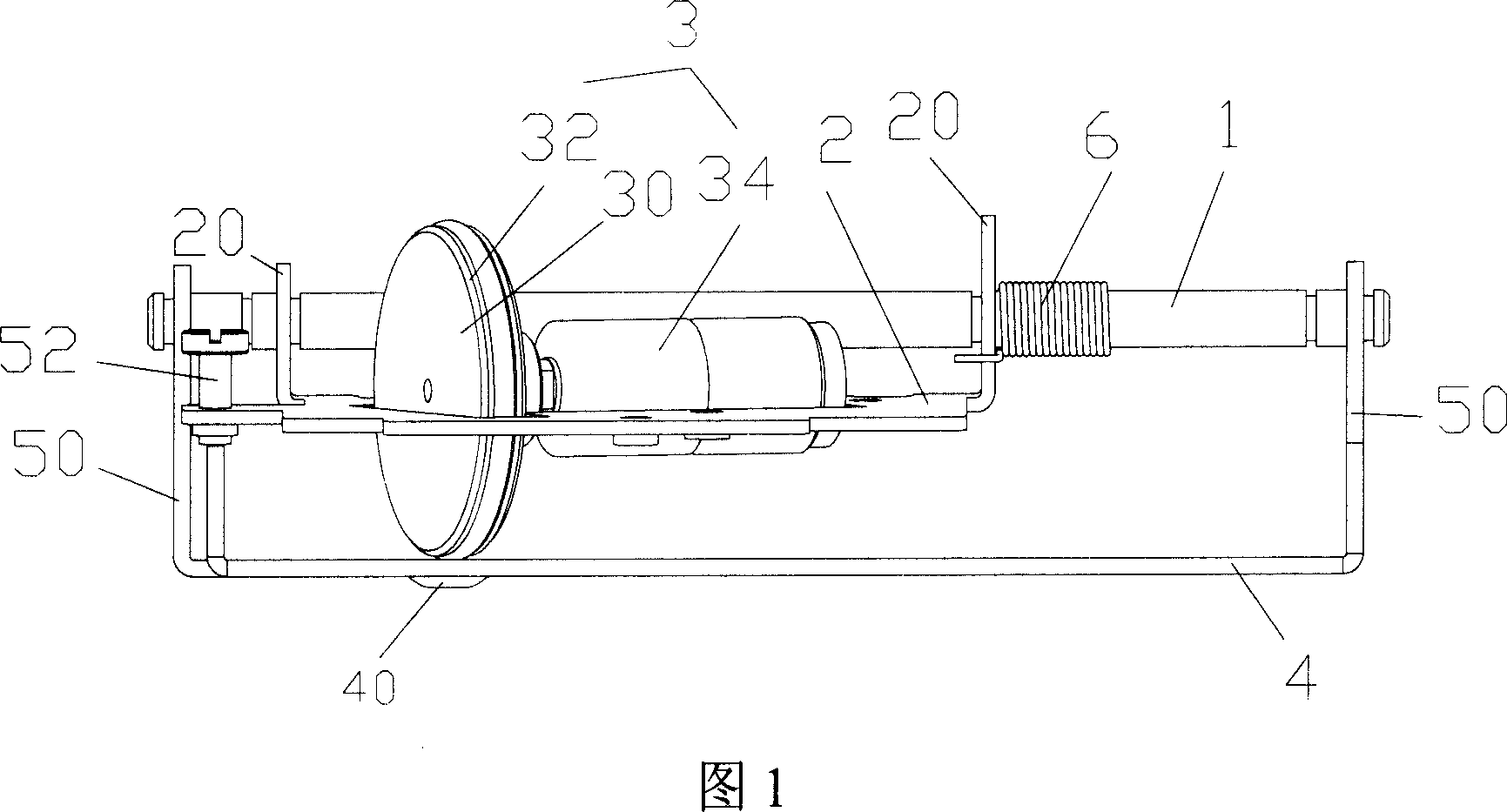

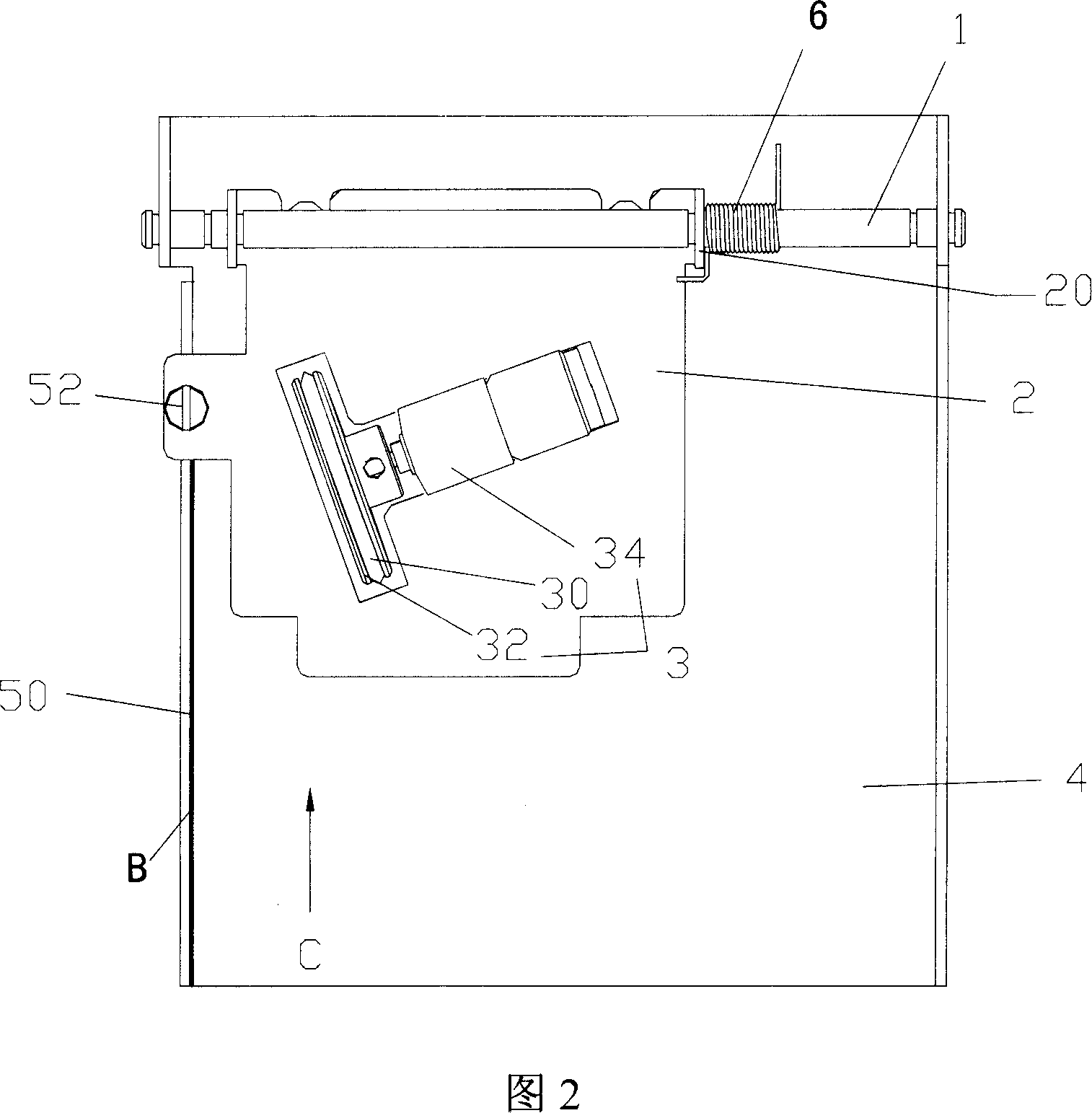

[0020] Referring to Fig. 1, the deviation correction mechanism includes a fixed shaft 1, a fixed plate 2, a deviation correction device 3 and a guide plate 4, the entire deviation correction mechanism is fixed on the paper transmission system through the guide plate 4, and the fixation plate 2 is used as a support plate of the deviation correction device 3, the The deviation correcting device 3 further includes two vertical arms 20 penetrating through and perpendicular to the guide plate 4 . A notch (not marked) matching with the deviation correcting device 3 is provided on the fixing plate 2 . In this embodiment, the notch is T-shaped.

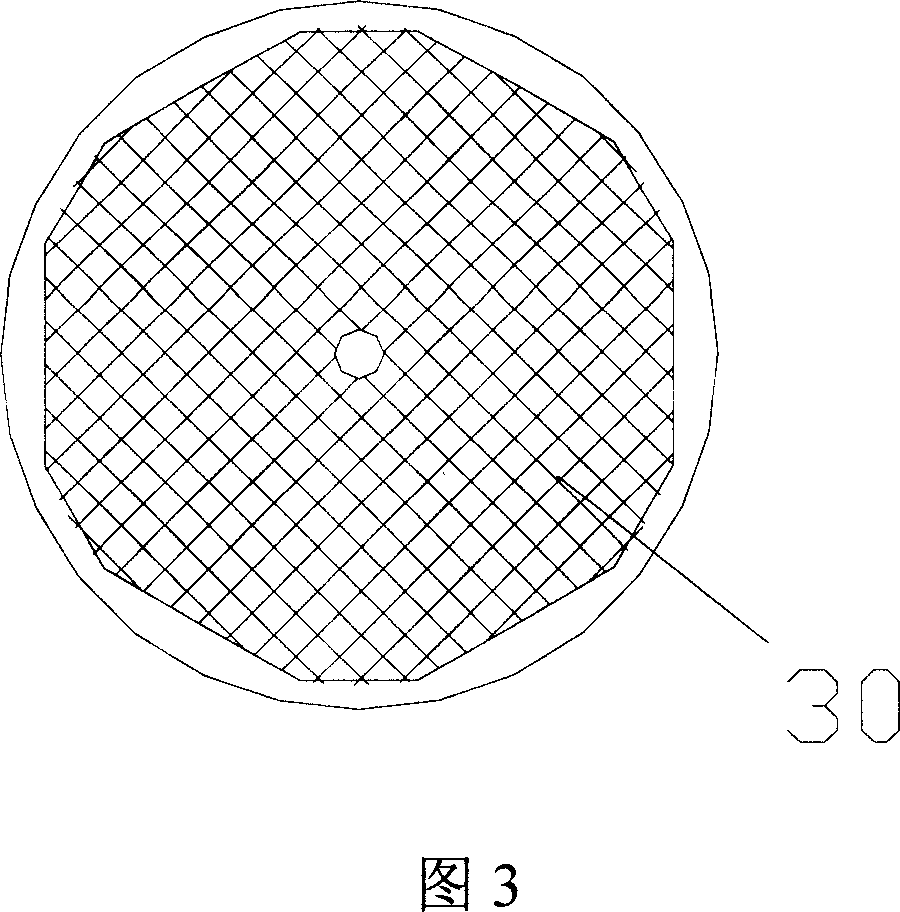

[0021] Referring to FIG. 1 and FIG. 2 , a deviation correcting device 3 is built horizontally in the gap, and the deviation correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com