Steel construction unit

A technology for steel structures and fixed parts, which is applied in building components, building structures, earthquake-proof and other directions, can solve the problems of difficult construction, increased cost, inconvenience, etc., and achieves the effect of less accessories, material saving, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

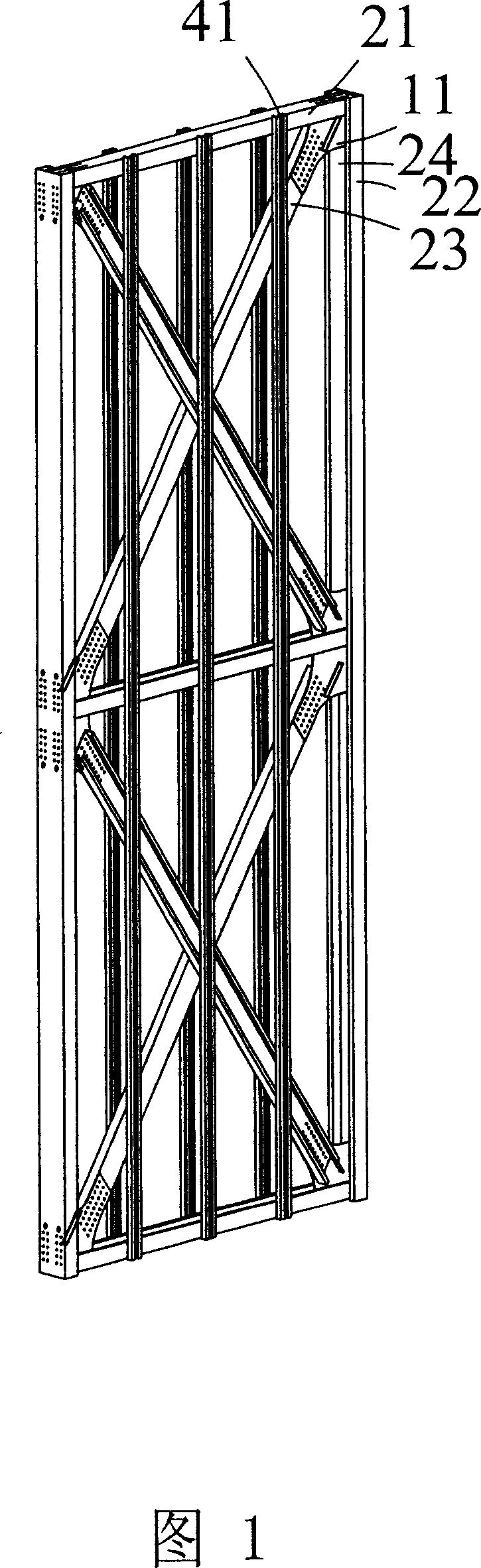

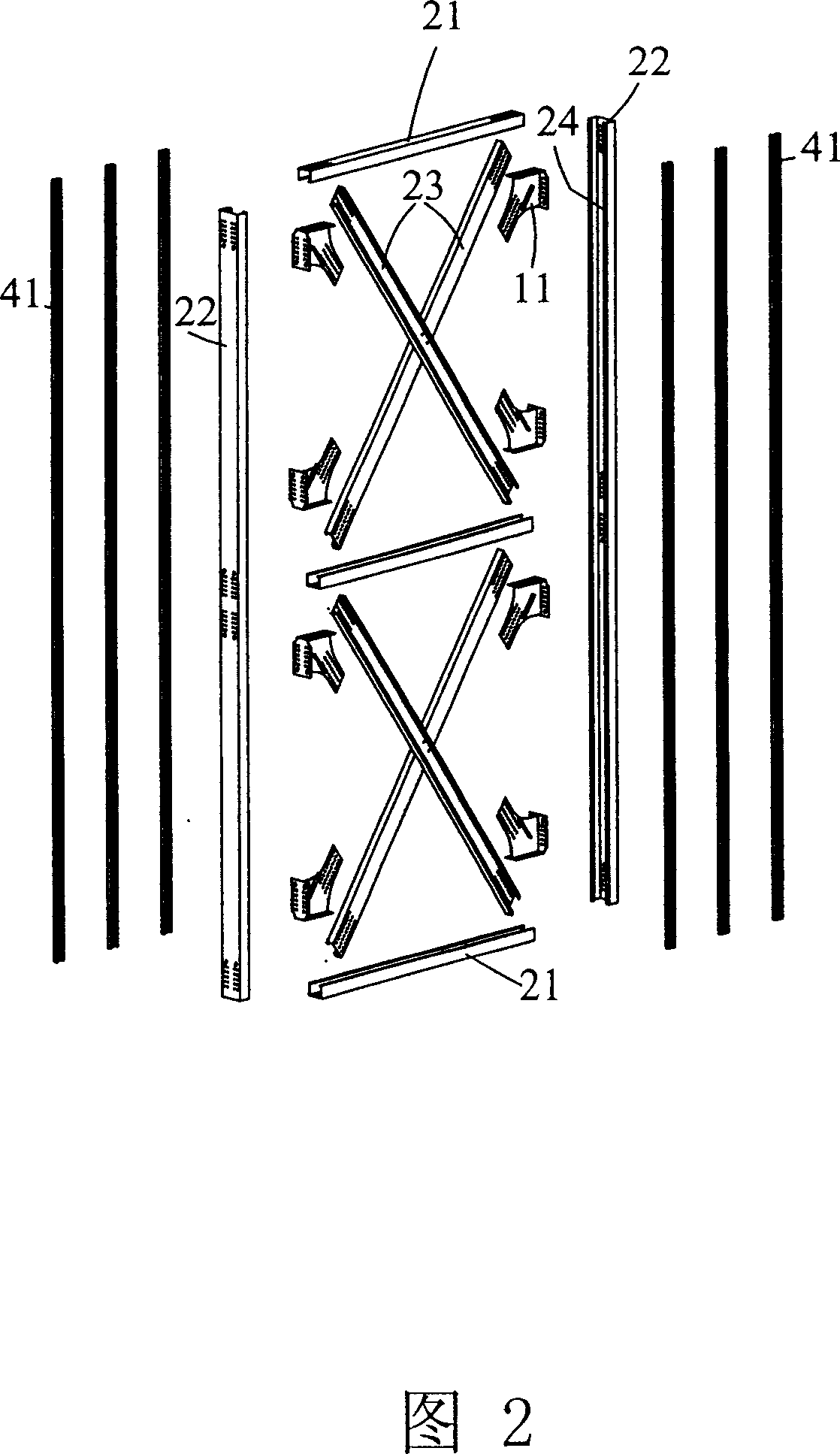

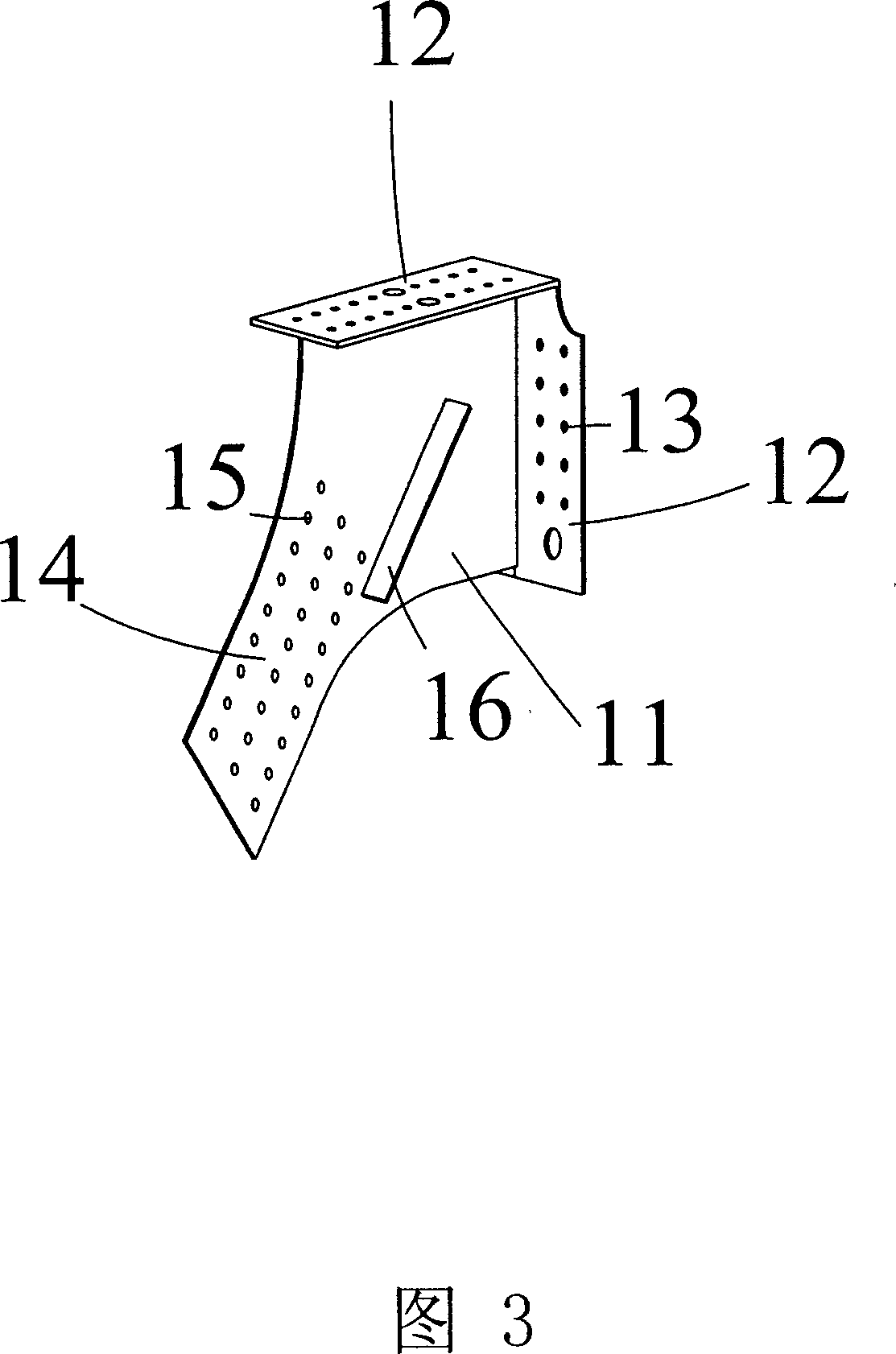

[0025] The present invention is a high-performance steel structure unit, as shown in Fig. 1, Fig. 2 and Fig. 3, the steel structure unit is provided with a connector 11, and one end of the connector 11 is provided with two fixing parts 12, and the two The fixed parts 12 are perpendicular to each other, and several mounting holes 13 are provided on the surface thereof. The other end of the connector 11 extends outward at 45 degrees to provide a fixed part 14. The surface of the fixed part 14 is provided with several mounting holes 15. The steel structure unit is provided with upper and lower base beams 21 and columns 22 on the left and right sides, and two beams 23 are intersected between the columns 22 on the left and right sides, and the columns 22 on both sides are in the shape of a C, forming a A mounting slot 24.

[0026] The composition of the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com