Grain distributor barrel subassembly production process

A technology of manufacturing process and dispenser, which is applied in the field of manufacturing process of grain dispenser components, can solve the problems of increasing or reducing capacity, etc., and achieve the effect of ingenious conception and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

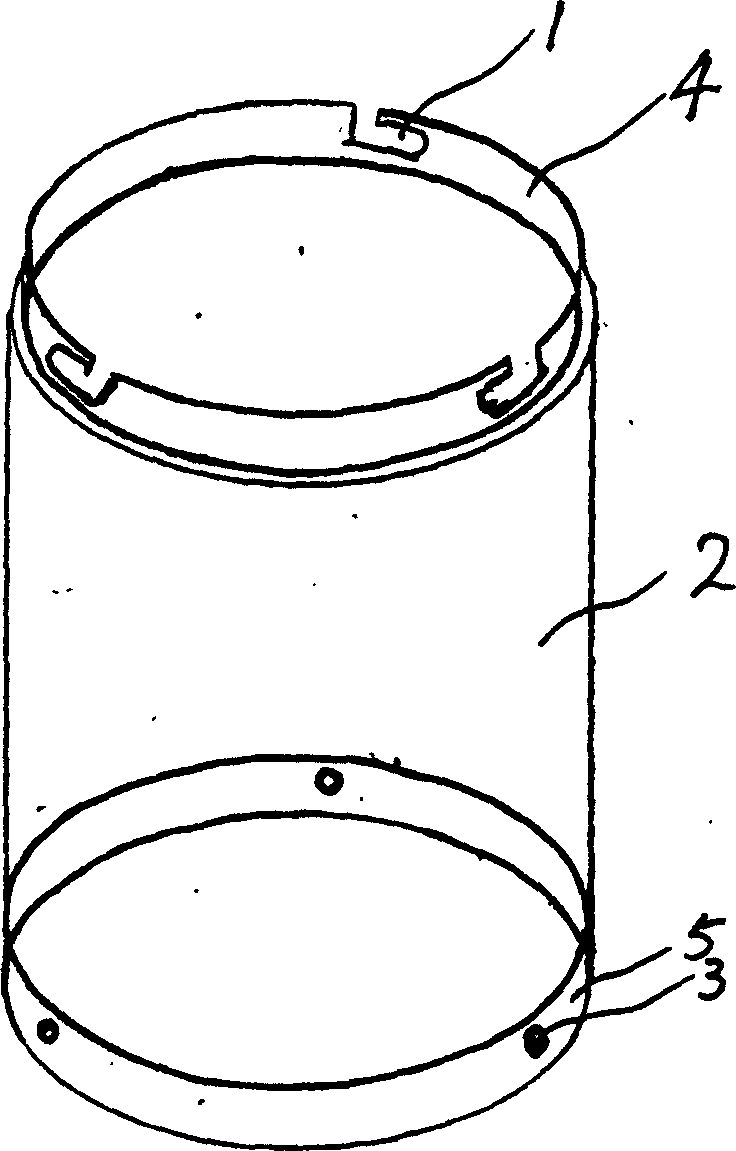

[0008] A manufacturing process for a barrel assembly of a grain dispenser, which mainly includes the following steps: a. The upper end of the barrel is provided with a connecting upper edge, and a fixing gap is provided on it; b. The lower end of the barrel is provided with a connecting edge that can be matched The connecting lower edge is sleeved with the connecting upper edge, and a fixing convex button matching the fixing notch is provided on it. The following is a detailed description of the components of the barrel body of the grain dispenser produced by this process in conjunction with the accompanying drawings. It is mainly composed of a hollow barrel body 2. The outer wall of the upper end of the barrel body 2 is concavely provided with a connecting upper edge 4, which There is a fixed notch 1 on the top, and the inner wall of the lower end of the barrel body 2 is concavely provided with a connecting upper edge 4 that matches the connecting upper edge 4, and a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com