Mold assembly for forming ophthalmic lens or lens blank and method of producing the same using the mold assembly

a mold and lens technology, applied in the field of mold assembly for forming ophthalmic lenses or lens blanks, can solve the problems of high-pressure molding, molds formed of resin materials undesirably deteriorating configurational accuracy, and contact lenses obtained by using molds with optical portions that may not have an accurately formed lens surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

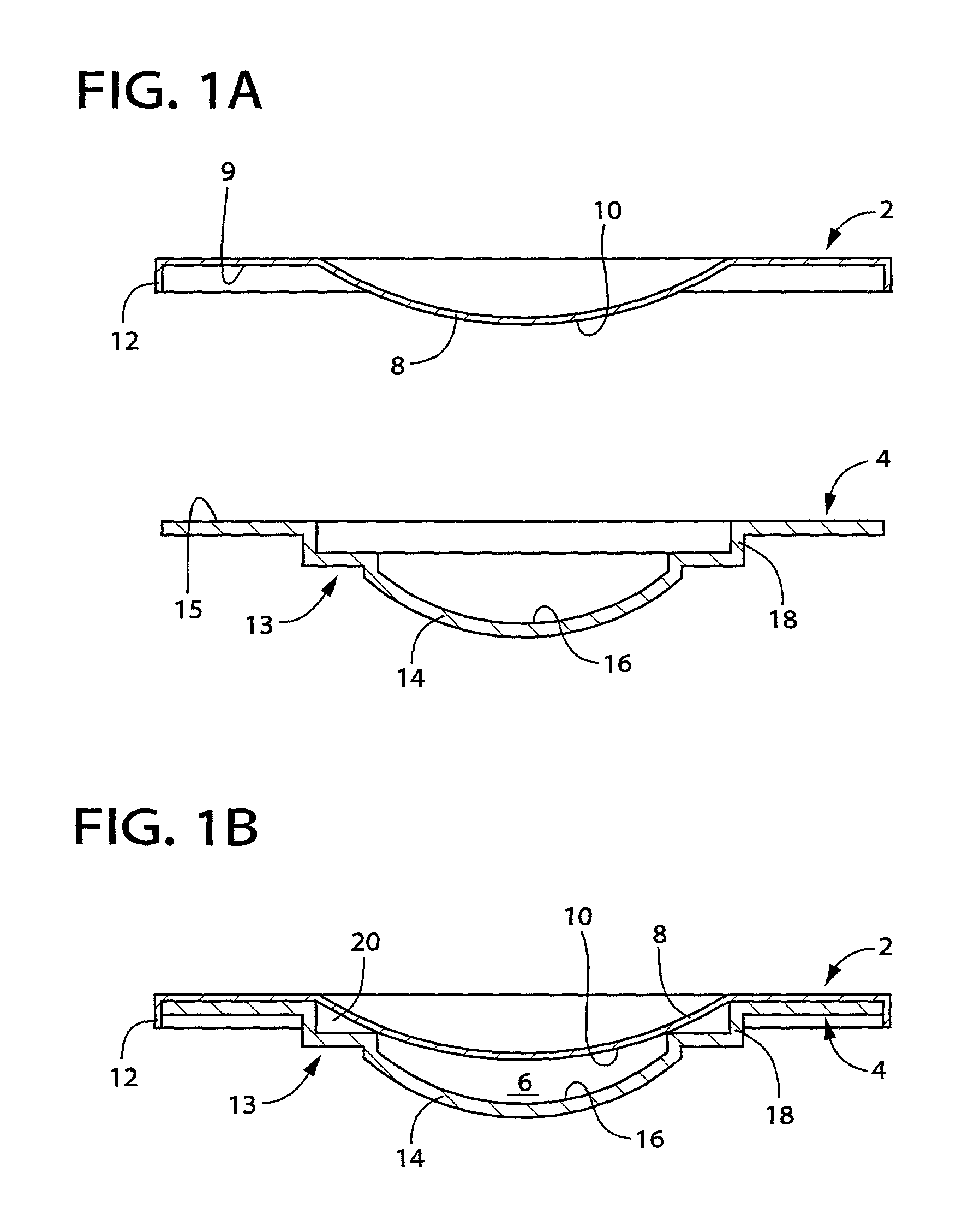

[0033] Referring first to FIGS. 1A and 1B, there is shown a mold assembly for forming an ophthalmic lens or a lens blank, which mold assembly is constructed according to one embodiment of the present invention. The mold assembly shown FIGS. 1A and 1B consists of a first mold in the form of a male mold 2 and a second mold in the form of a female mold 4. As shown in FIG. 1B, the male and female molds 2, 4 are assembled together to define therebetween a mold cavity 6 whose profile follows that of an intended ophthalmic lens, e.g., a contact lens in this embodiment.

[0034] The male mold 2 is a generally disc-shaped member, and has a protruding portion 8 which protrudes downwardly from its central portion as seen in FIG. 1A and which has a curved convex configuration. A central portion of the lower surface of the protruding portion 8 serves as a molding surface 10 (lens-forming surface) for forming a back surface (i.e., base curved surface) of the intended contact lens. The base curve-mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com