Gas burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

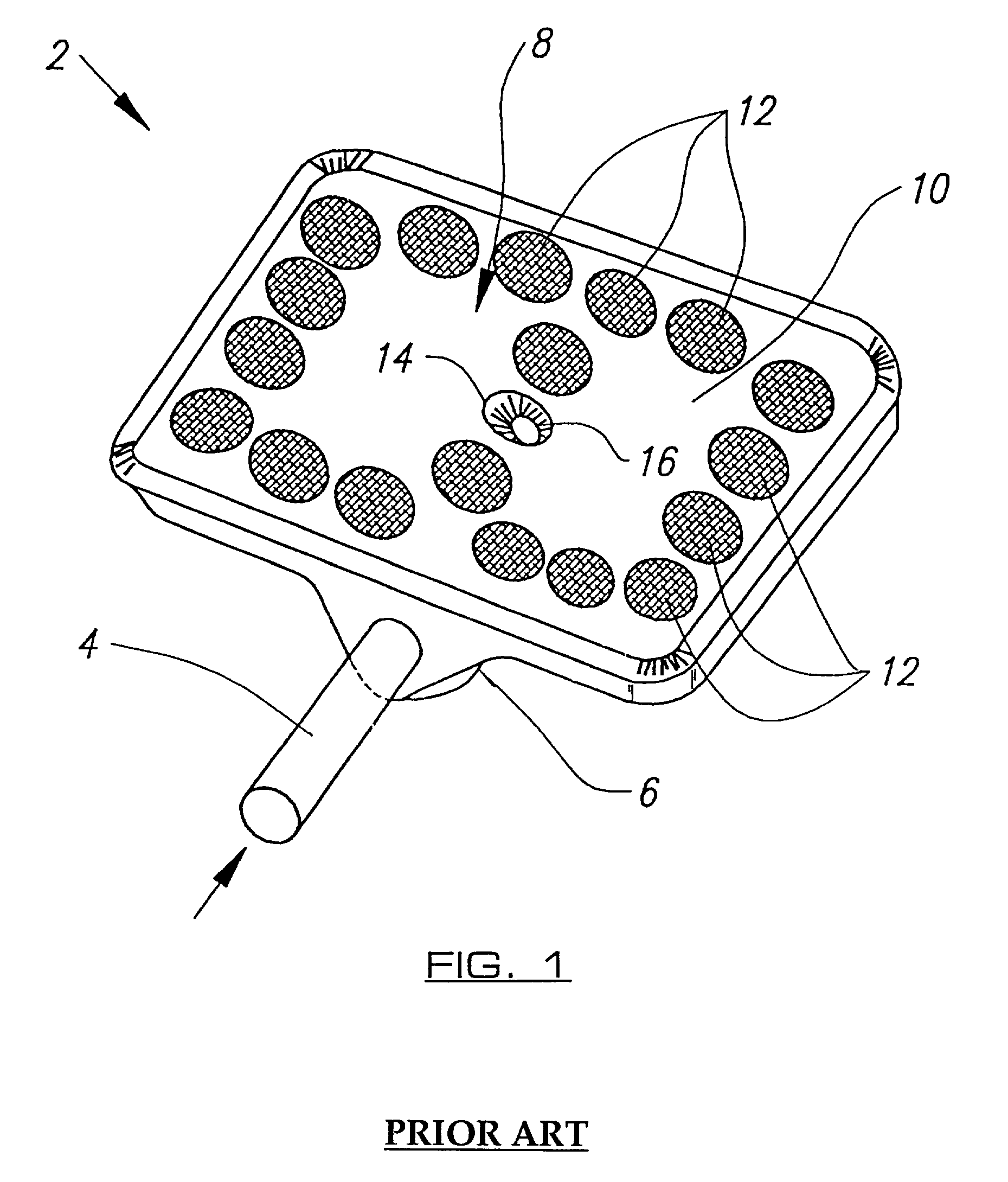

[0026] Referring firstly to FIG. 1 there is shown a burner head 2 of prior art configuration comprising a gas feed tube 4 which passes into a chamber 6 disposed underneath a combustion surface indicated generally by reference numeral 8. It should be pointed out that the burner heads shown in both FIGS. 1 and 2 are conventionally rotated through 180.degree. about the axis of the feed tube so that the combustion surface faces downwardly and the combustion which occurs thereon provides a grilling effect on products beneath the said burner head.

[0027] The combustion surface 8 is comprised of a punched template 10 which overlays two separate sheets of gauze arranged perpendicularly to one another to create a sufficient resistance to the flow of gas from within the chamber 6 through said sheets of gauze in the regions of apertures 12 provided in the punched template 10.

[0028] The combustion of the gas approximate or on the combustion surface 8 heats both the template 10 and the portions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com