Method and apparatus for completing multiple production zones from a single wellbore

a production zone and wellbore technology, applied in the direction of directional drilling, wellbore/well accessories, sealing/packing, etc., can solve the problems of affecting the economics of the well, affecting the commercial standpoint merely, and being extremely difficult, if possible at all

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

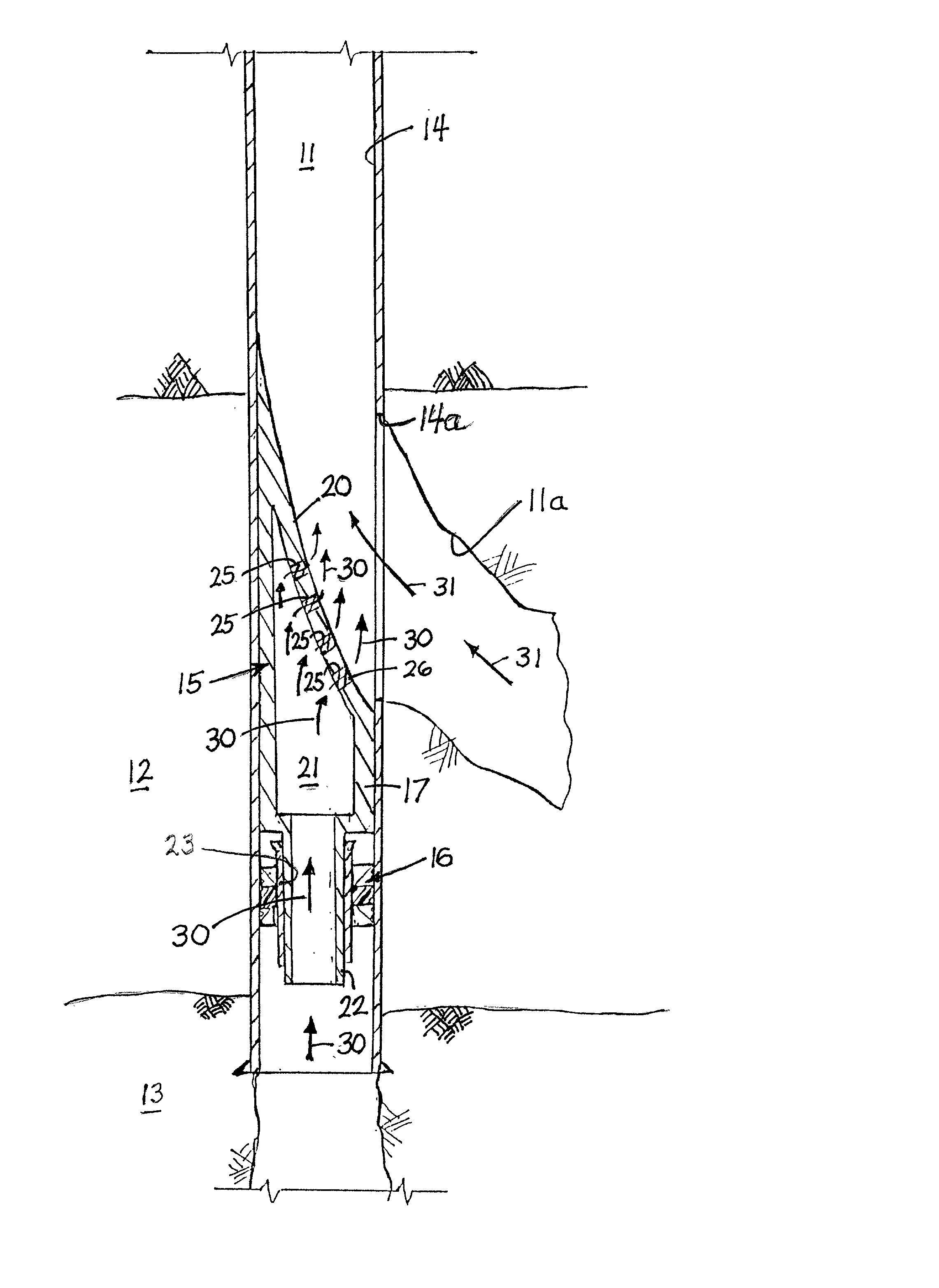

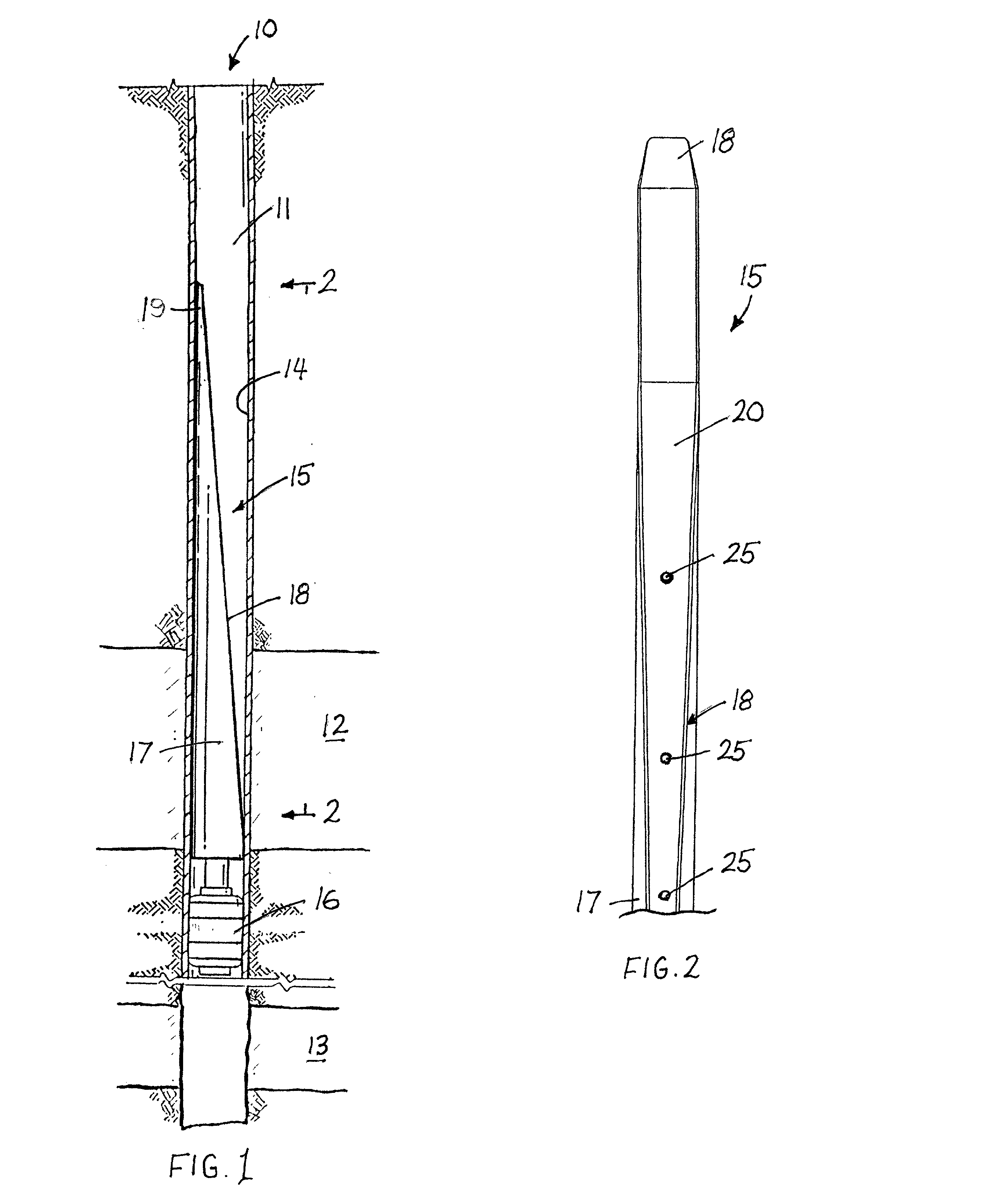

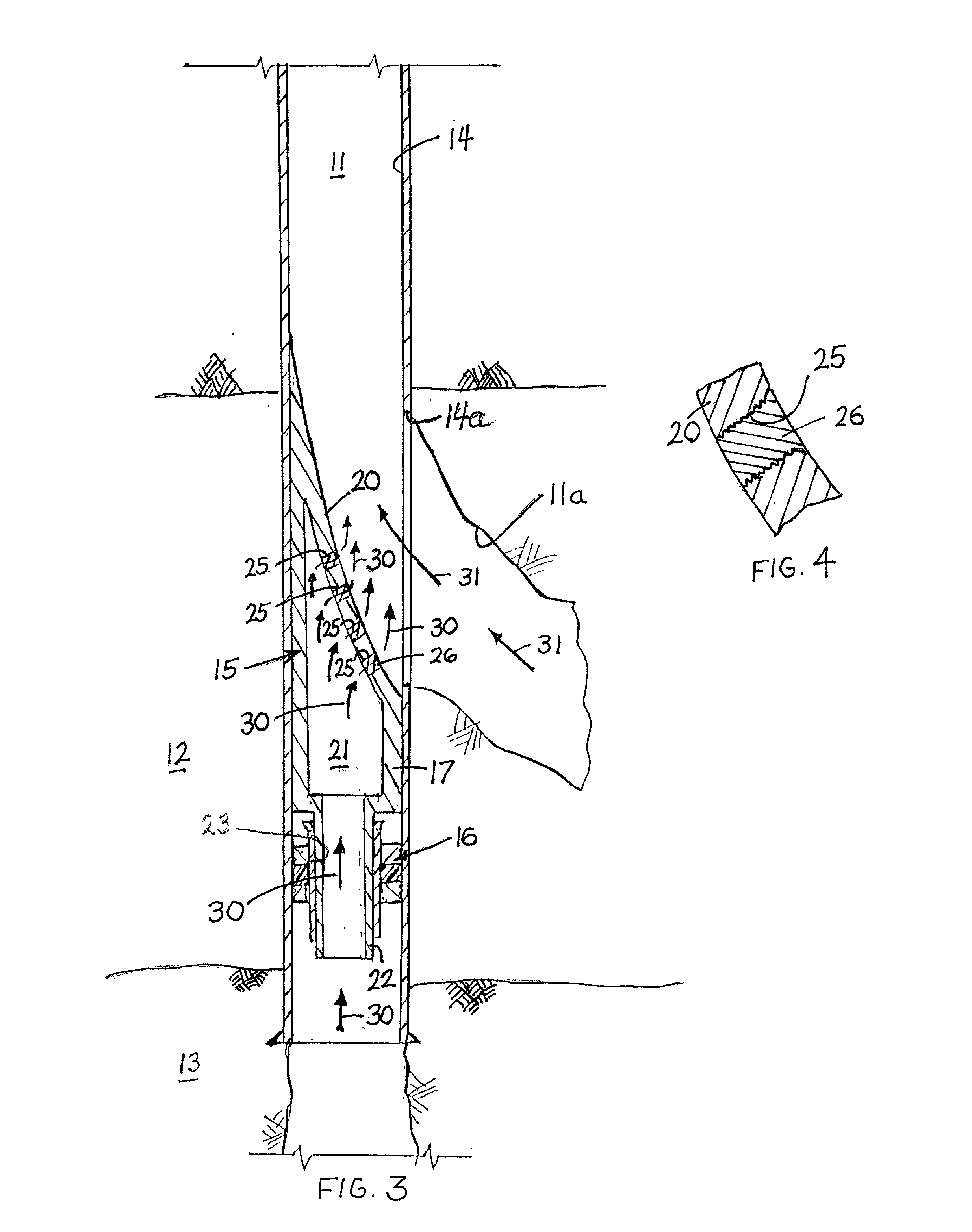

[0019] Referring more particularly to the drawings, FIG. 1 illustrates a portion of a well 10 having a wellbore 11 which has been drilled through an upper production formation or zone 12 and a primary, lower production formation of zone 13. Wellbore 11 is shown as being cased with casing 14 to a point near the upper end of lower zone 13 which, in turn, is "open hole" completed. However, as will be fully understood in the art, lower zone 13 may also be cased by extending casing 14 through lower zone 13 and then perforating the casing to establish fluid communication between zone 13 and wellbore 11 without departing from the present invention. Also, as will be understood, although not shown, casing 14 is normally cemented in place within the wellbore. Further, while the present invention will be described in relation to a substantially vertical wellbore 11, it should be understood that the present invention is equally applicable for use in horizontal or inclined wellbores and accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com