Mud Flap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

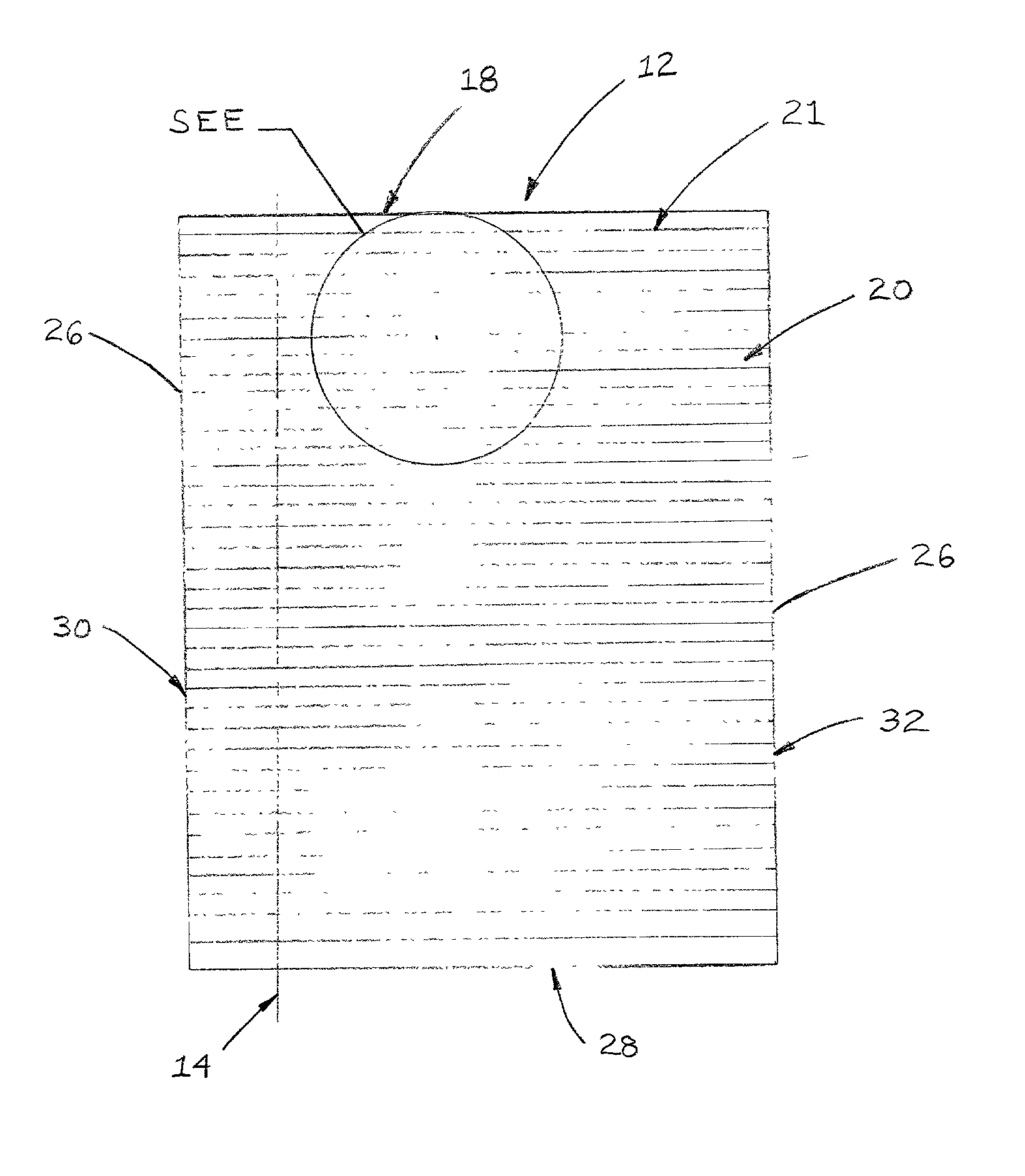

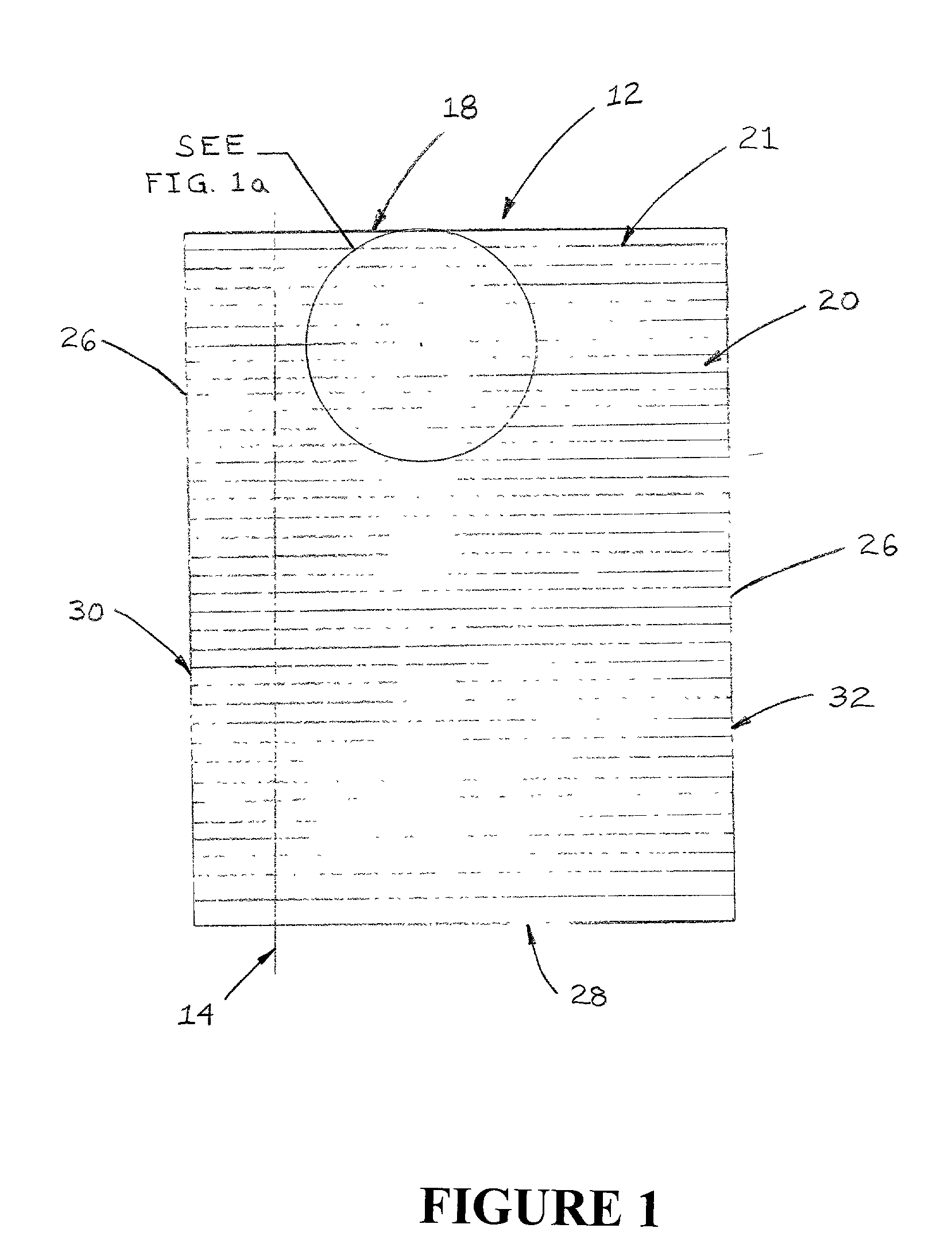

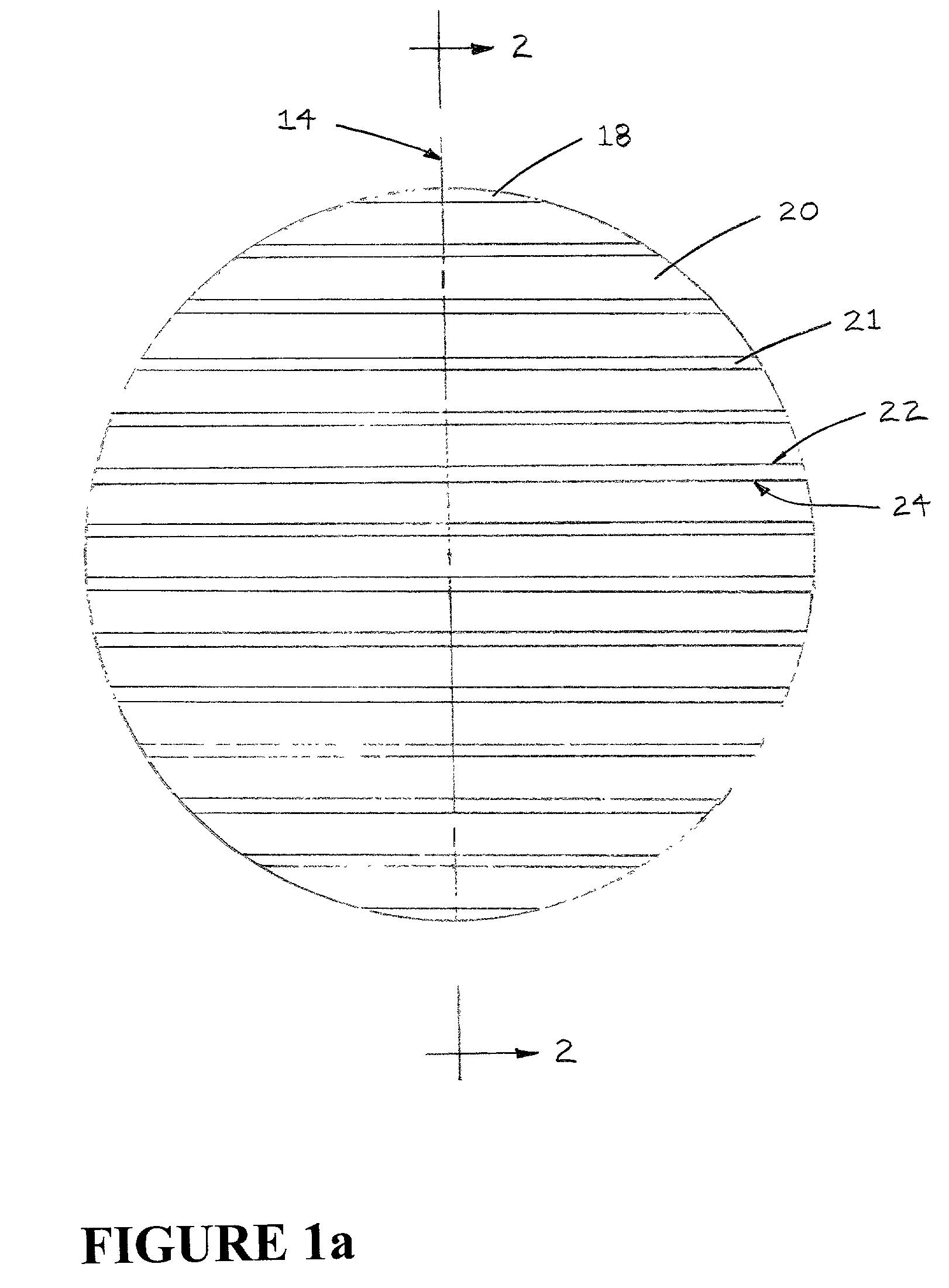

[0022] Referring now to the drawings, the apparatus of the invention is illustrated by FIGS. 1 through 8. The preferred embodiment of the invention is illustrated in FIGS. 1 and 2. As shown in FIGS. 1 and 2, the invention comprises a mud flap for deflecting water and roadway debris propelled by the rotating tires of a moving motor vehicle. The mud flap comprises deflecting panel 12 which may be manufactured using any suitable material conventionally used to make mud flaps such as polypropylene or some other elastomeric or polymeric material. It is also contemplated within the scope of the invention that the deflecting panel may be made from metal. Preferred deflecting panel 12 is preferably manufactured using current plastic molding technology. In the preferred embodiment of the invention, the plastomeric material used to make panel 12 is heated until it becomes a liquid. The liquid may then be introduced into a mold where it is allowed to cool and solidify.

[0023] As illustrated in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap