Vehicle crash wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

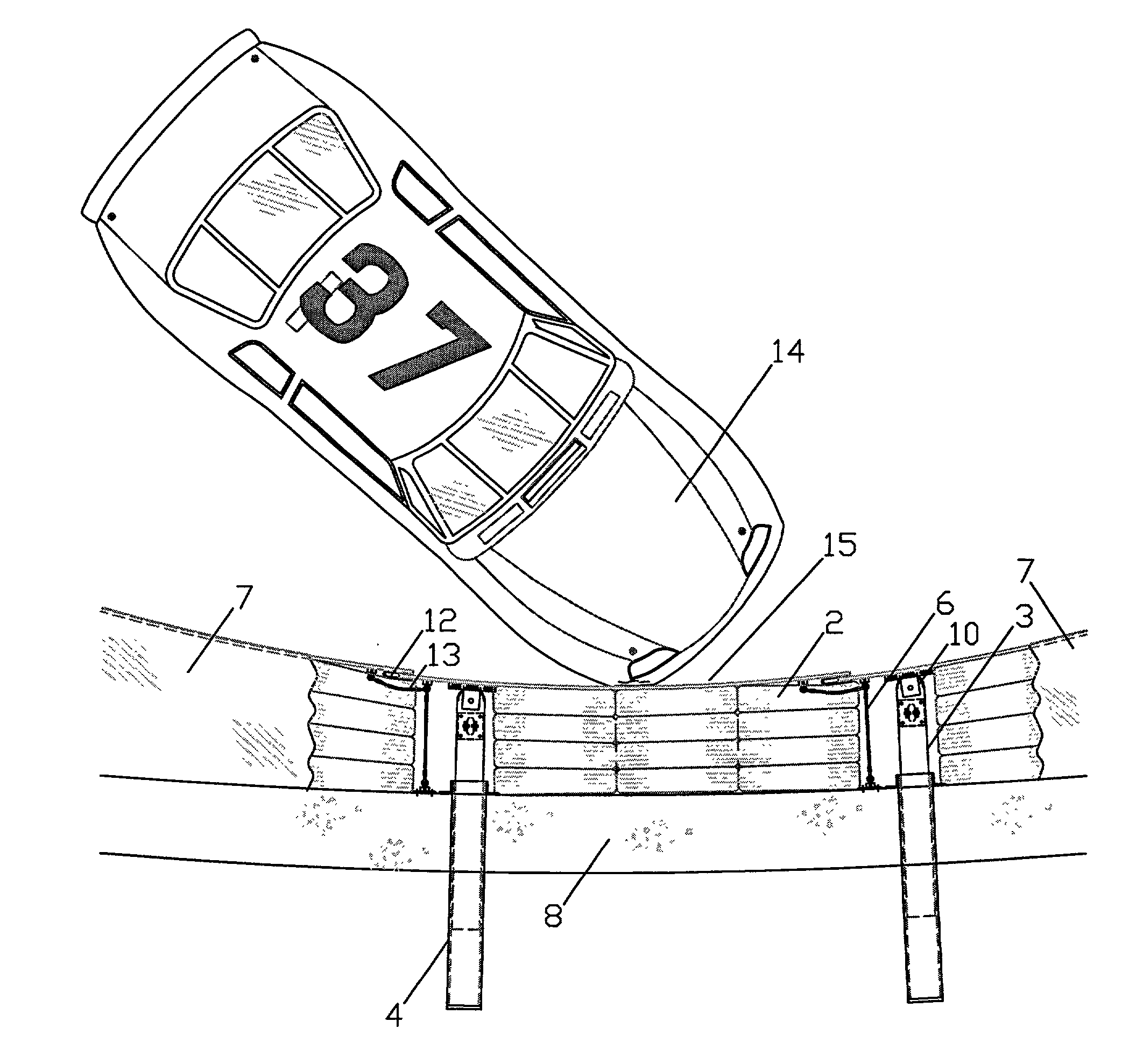

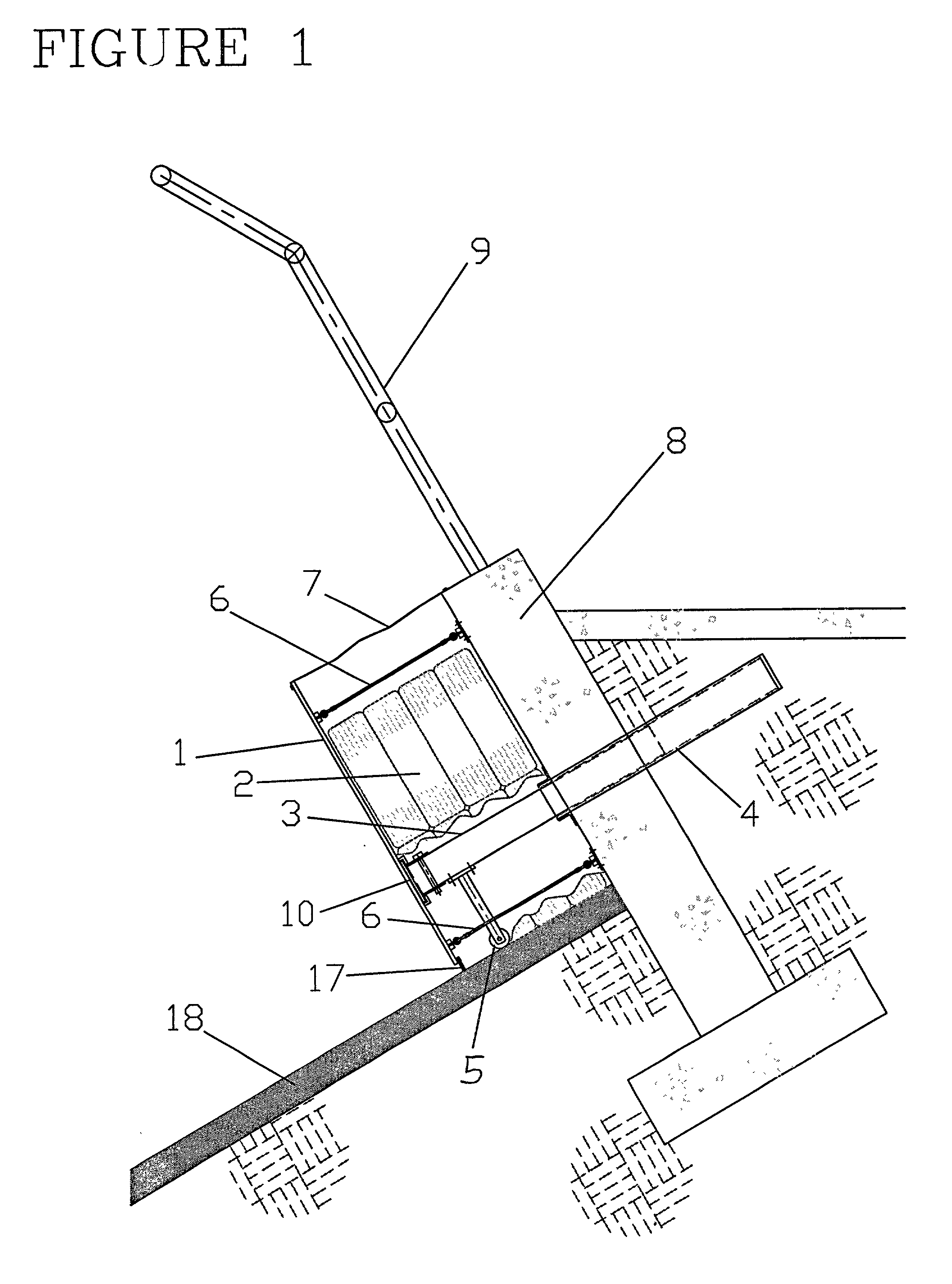

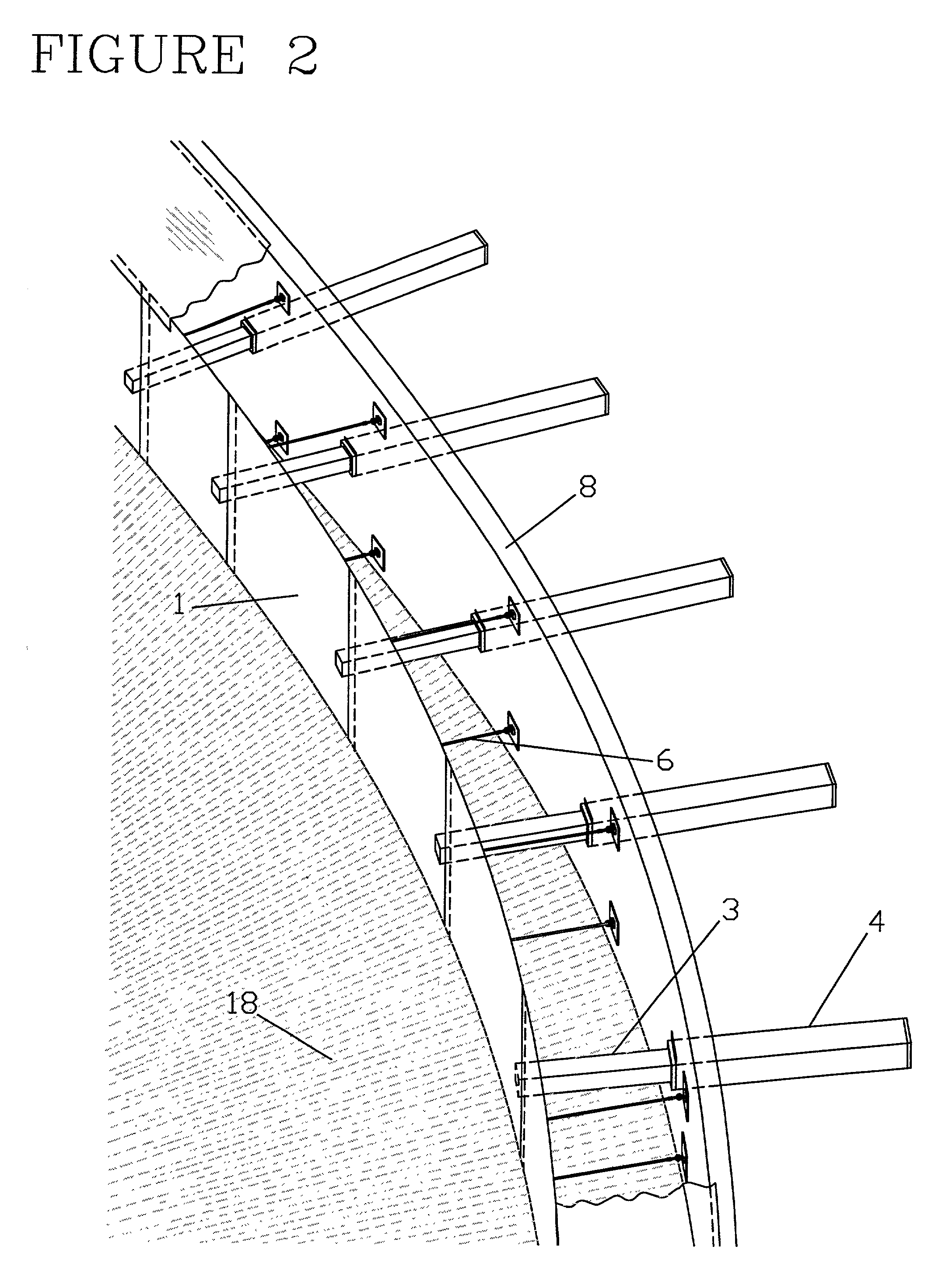

[0021] Operation and use of the vehicle crash wall is simple and straightforward. It has over-lapping metal impact plates which are attached to a retaining wall by anchoring cables and a plate stabilizer tube. Impact absorbent filler material is located between the impact plate and retaining wall cushioning the impact and helping to uniformly dissipate the impact force along other plates.

[0022] It may be utilized in many settings, including racetracks, freeways, highways, bridges and any area frequented by vehicles. The impact absorbent material is composed of rubber tires but may be made from any other material suitable for this purpose.

[0023] In FIG. 1, the impact plate, 1, is located horizontal to the retaining wall, 8, which runs parallel to a fence, 9, that catches debris. Located at the bottom of the impact plate, 1, is a debris brush, 17. The retaining wall, 8, has a female receiving tube, 4, imbedded through the middle of said retaining wall, 8, which extends behind said ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com