Method and apparatus for performing dynamic mechanical analyses

a dynamic mechanical analysis and analysis method technology, applied in the direction of measuring devices, material strength using repeated/pulse forces, instruments, etc., can solve the problem of displacement not representing an effective tensile elongation of the entire specimen, the damping constant of an elastic specimen cannot be determined, and the specimen is not coupled correctly to the excitation devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

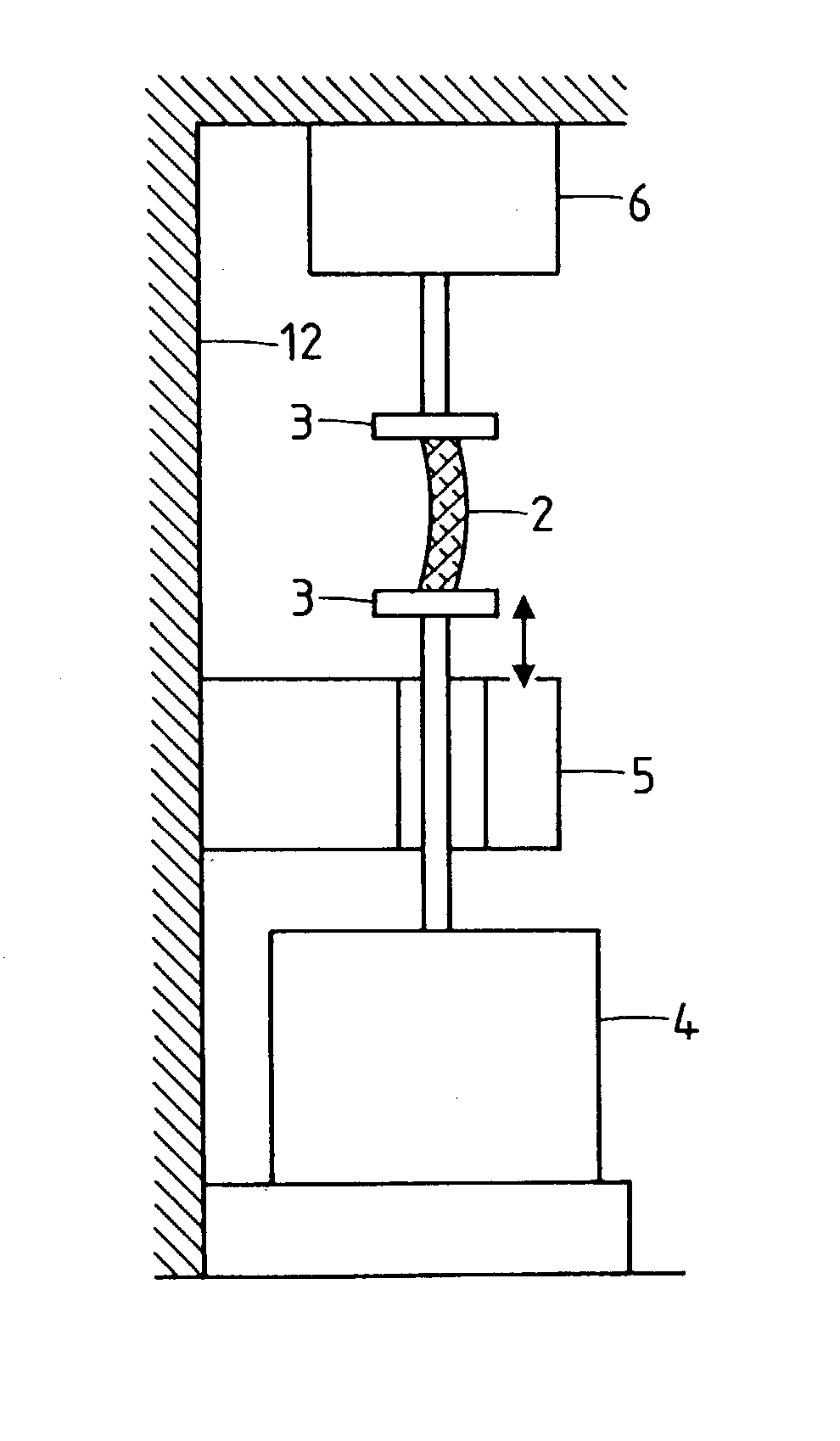

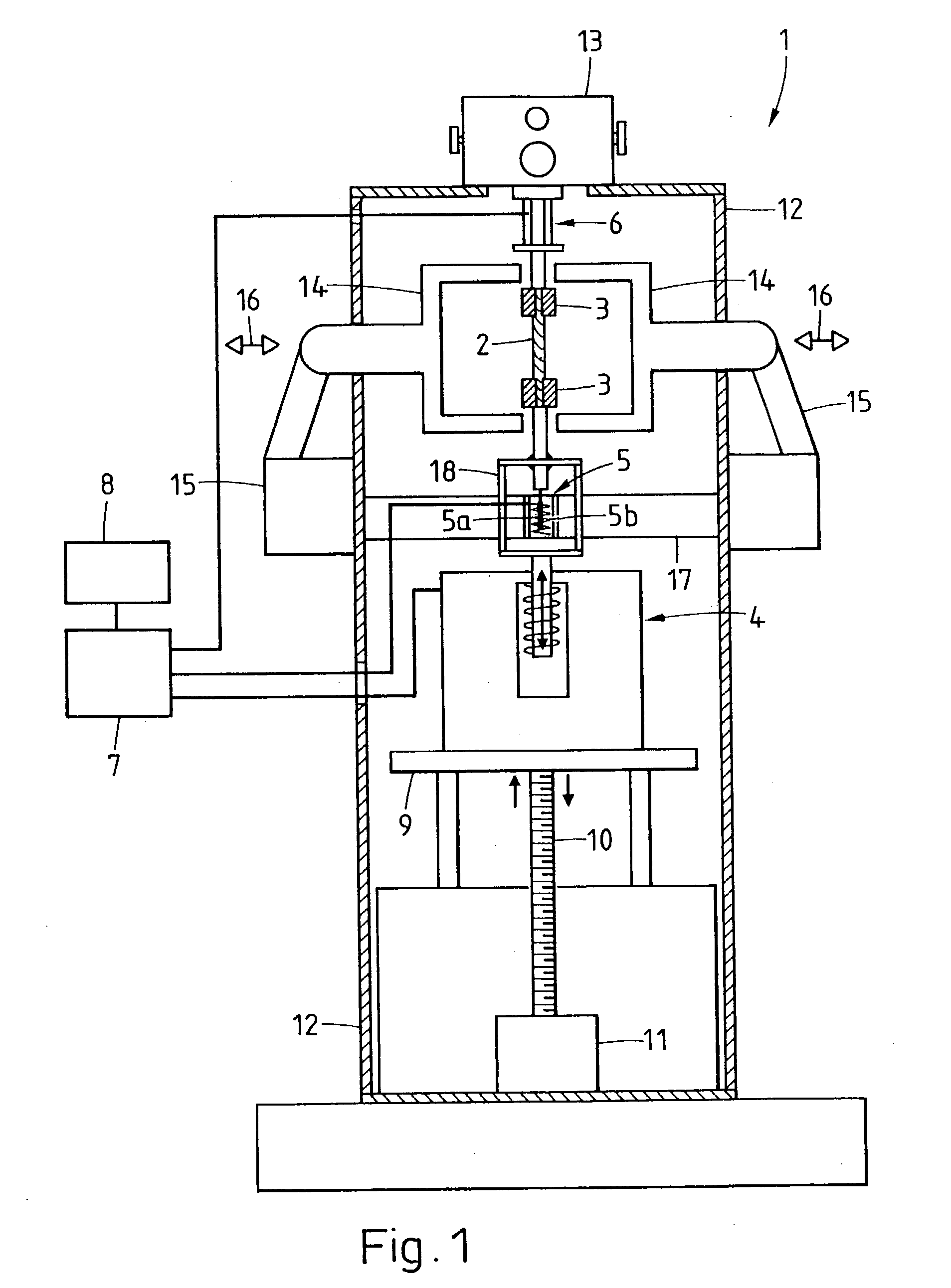

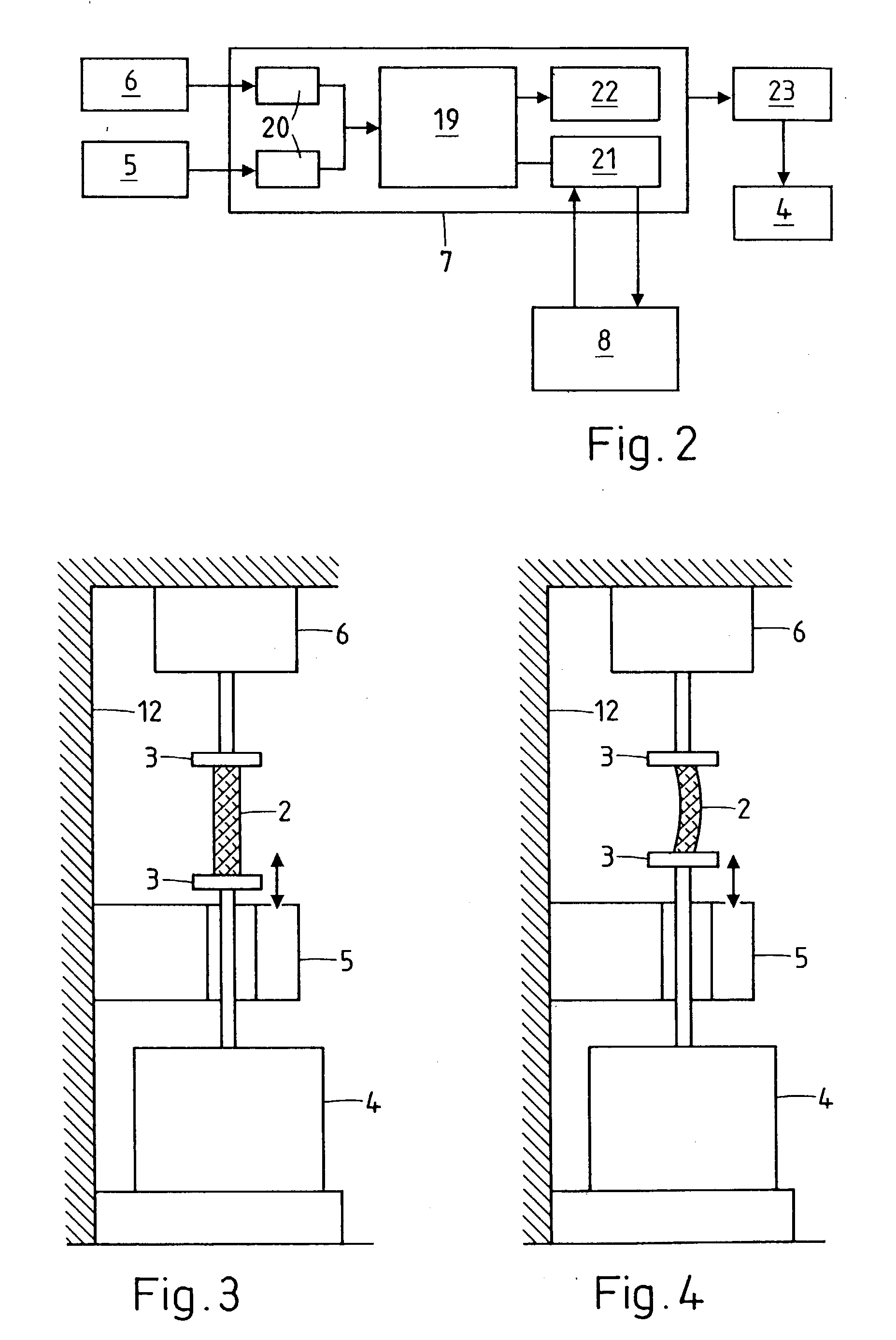

[0029] FIG. 1 illustrates an apparatus 1 for performing dynamic mechanical analyses on a test specimen 2. The specimen 2 is held by a holder device 3, and an excitation device 4 applies a static pre-tensioning force and a time-variable excitation force to the specimen. The deformation of the specimen 2 is measured by at least one displacement sensor 5. The apparatus 1 preferably includes a force sensor 6 which can measure the entire force applied to the specimen 2 or may be designed to measure only the dynamic portion of the force. The excitation device 4, the displacement sensor 5, and the force sensor 6 which may be provided in some embodiments of the apparatus are tied to a control- and data-collecting device 7 which is connected to an operating device or input / output device 8. It is considered self-evident that the displacement of the lower end of the specimen could also be transmitted through a transfer mechanism to a displacement sensor mounted in the upper part of the apparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com