Wave powered propulsion systems for submarines and quasi-dipped watercrafts

a technology of wave power and submarines, applied in underwater equipment, special-purpose vessels, vessel construction, etc., can solve the problems of many failures, and achieve the effect of zero wind load and minimal water resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

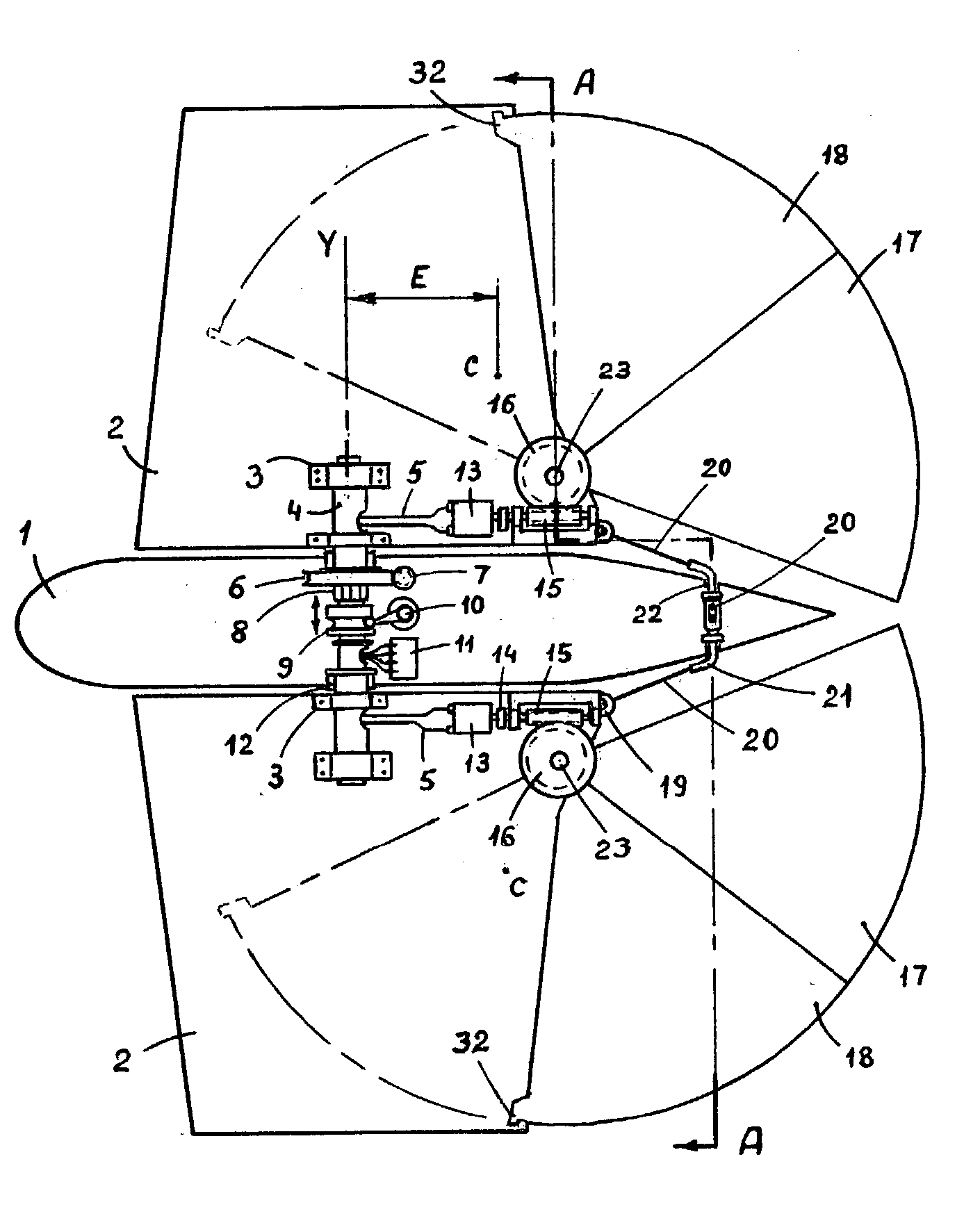

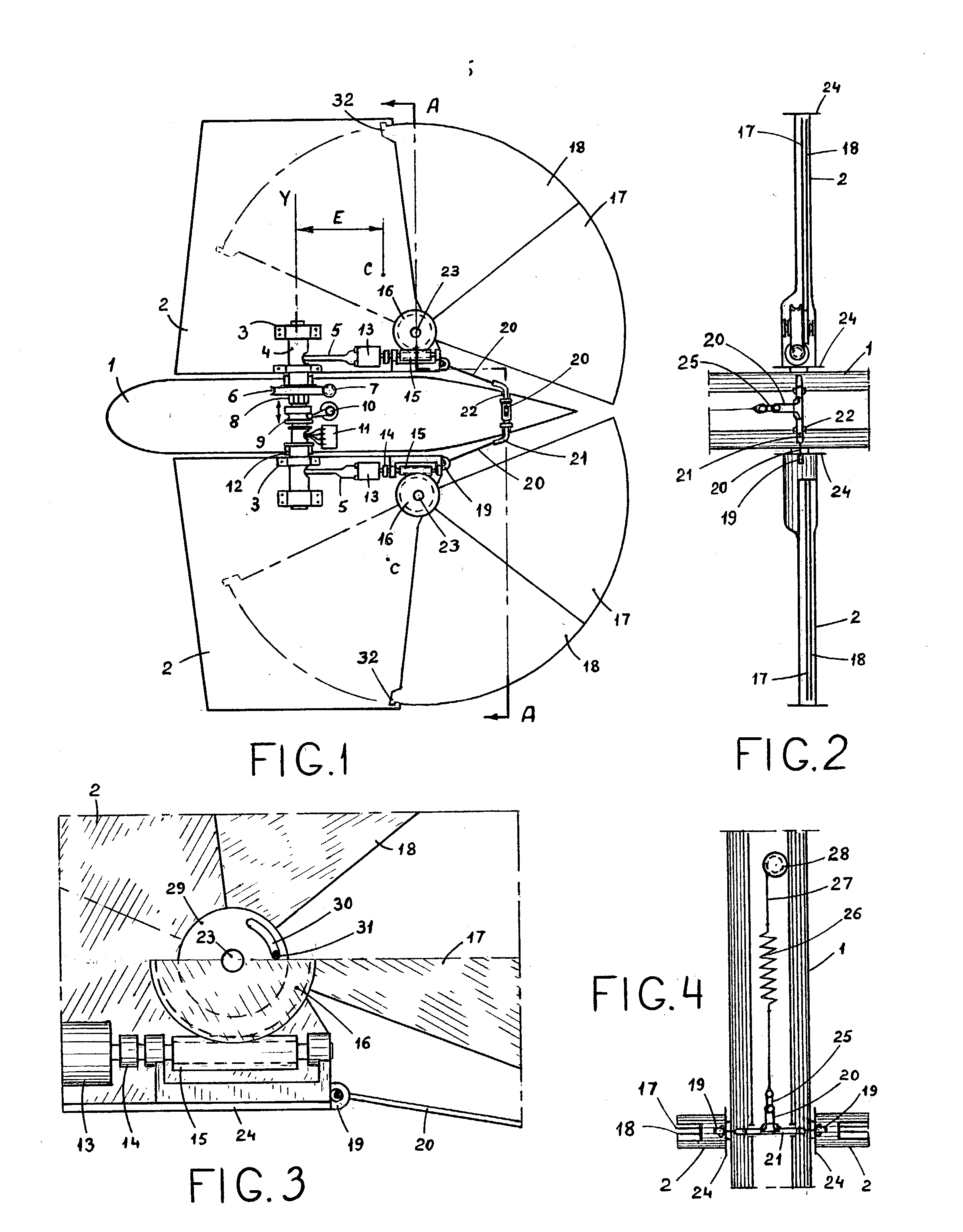

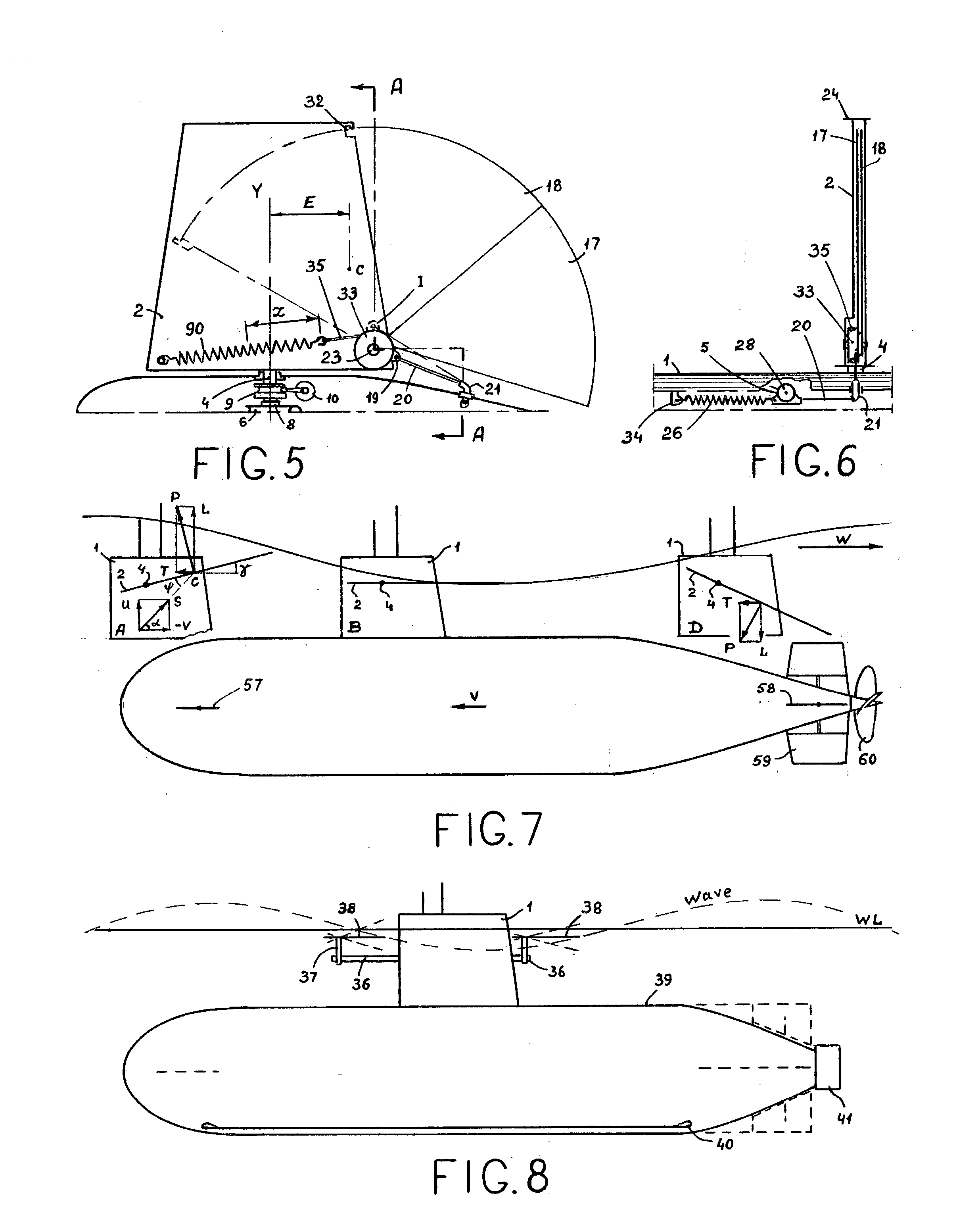

[0043] 1. Submarine wave powered (WP) propulsion system. Basic design. Claim 1.

[0044] The basic design of submarine WP propulsion system (FIG. 8) consists of two elastically deflecting foils 38 attached to a submarine sail with arms 36 and holders 37. On tested submarine model the holders has held the foils 38 with glue bond 43 (FIG. 9) via elastic strip 42 functioning as a torsion. Because the eccentricity E presents here the wave hydraulic head P deflects the foils around axis's Y creating vertical and horizontal components of the force P. Tremendous inertia forces of the body mass 39 equilibrate the vertical components L while the horizontal components T are thrusts propelling the submarine model.

[0045] Notice.

[0046] The scheme of thrust generation is shown also for a submarine using its expandable diving rudders 2 (FIG. 7) as spare WP propulsion plant. We see three positions of the submarine sail 1. If the wave moves to right (with velocity W) then an ascending wave front angles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com