Airtight container

a container and airtight technology, applied in the field of hermetically sealed containers, can solve the problems of unsatisfactory hermetic seals of the above conventional art teachings, difficult to bring the inside surface of the groove into close contact with the surface of the protruding protruding, and the lid body cannot be closed, etc., to achieve the effect of outstanding hermetic sealing capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

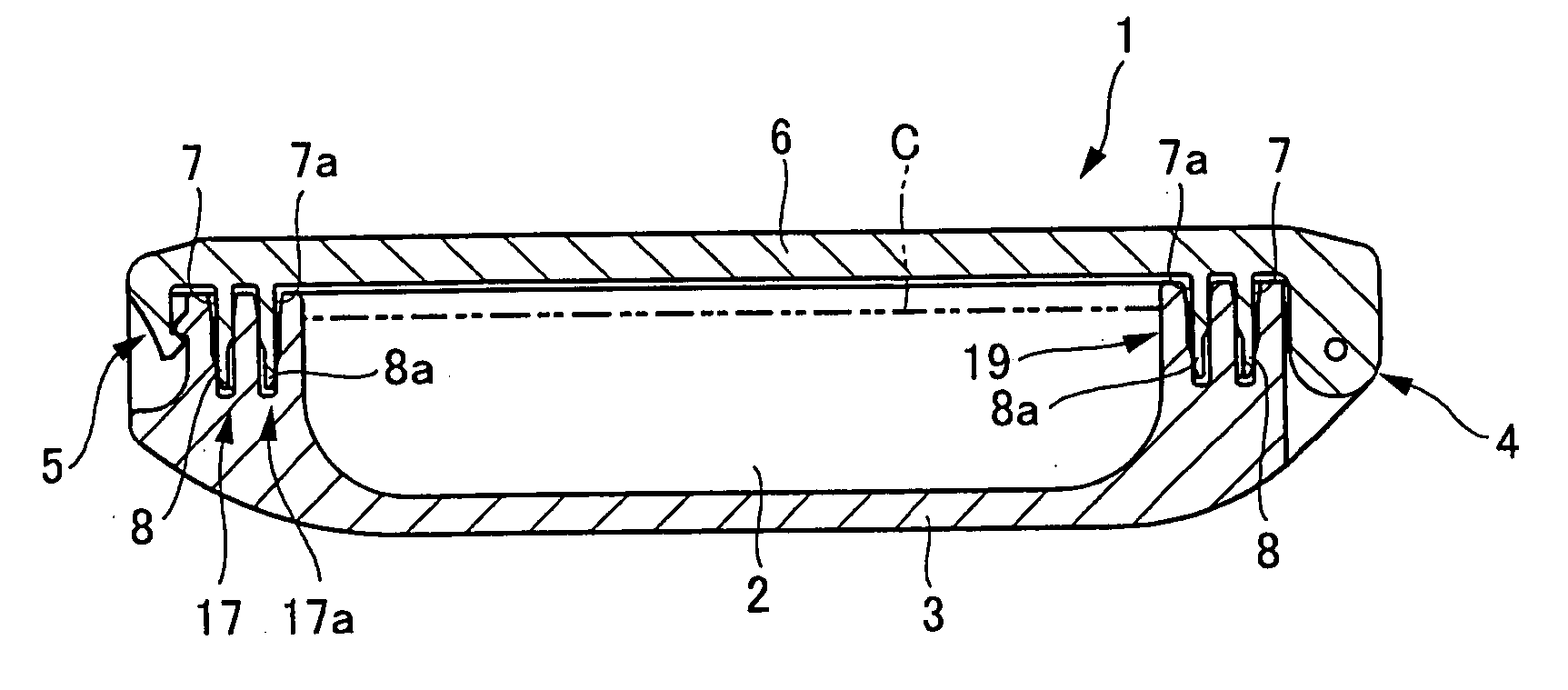

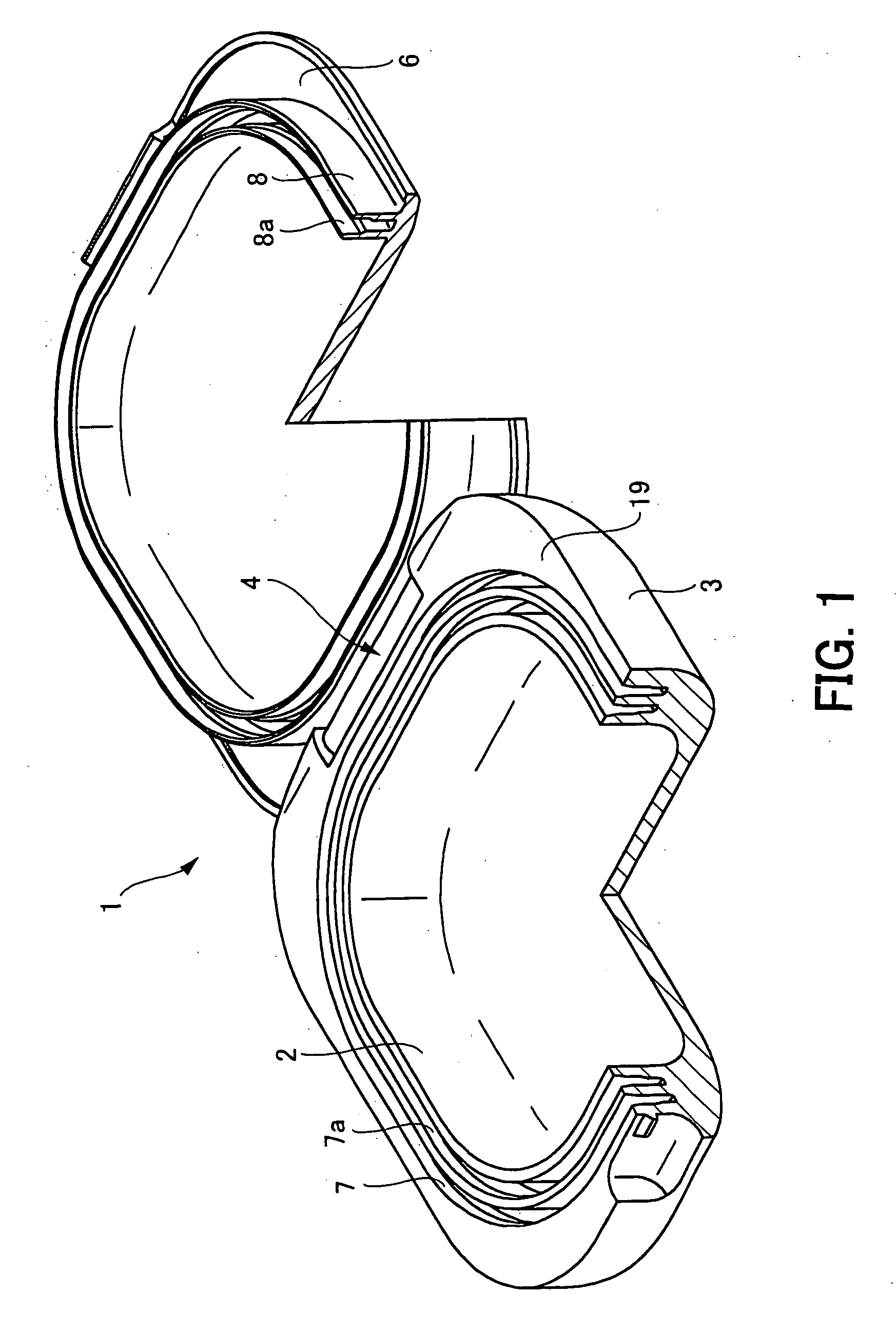

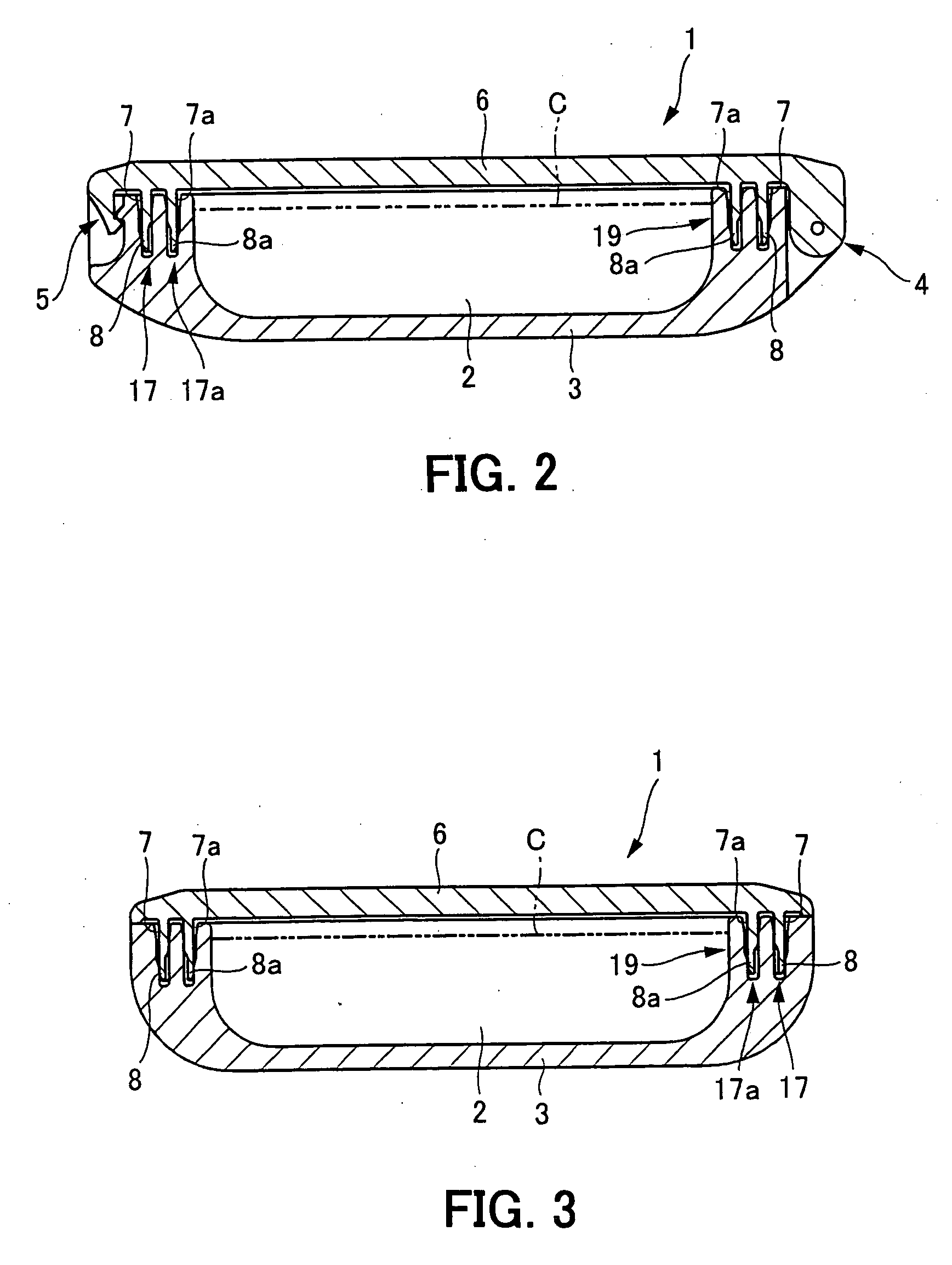

[0021] A hermetically sealed container in accordance with an embodiment of the present invention will hereinafter be described in detail with reference to the accompanying drawings. FIG. 1 through FIG. 4 show a portable cosmetic container 1, as an example of the hermetically sealed container, filled with a cosmetic substance C that includes a volatile component. As shown in the figures, this cosmetic container 1 mainly comprises a synthetic resin container body 3 formed with a storage section 2 containing the cosmetic substance C that includes a volatile component, and a synthetic resin lid body 6 which is pivotally coupled to one end of the container body 3 by a hinge 4 so as to permit opening and closing of the container body 3, and which is disengageably engaged to the other end of the container body 3 by hook means 5 so as to retain the container body 3 in a closed condition.

[0022] Basically, the cosmetic container 1 of the present embodiment is configured so that annular sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com