Perimeter-cooled stage 1 bucket core stabilizing device and related method

a stabilizing device and bucket core technology, applied in the direction of manufacturing tools, foundry patterns, foundry moulding apparatus, etc., can solve the problems of not being able to simply scale up the stage 2 bucket core for use in the stage 1 and out of tolerance wall thicknesses in the shank portion of the bucket, etc., to achieve stress, particularly at the intersection of printouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

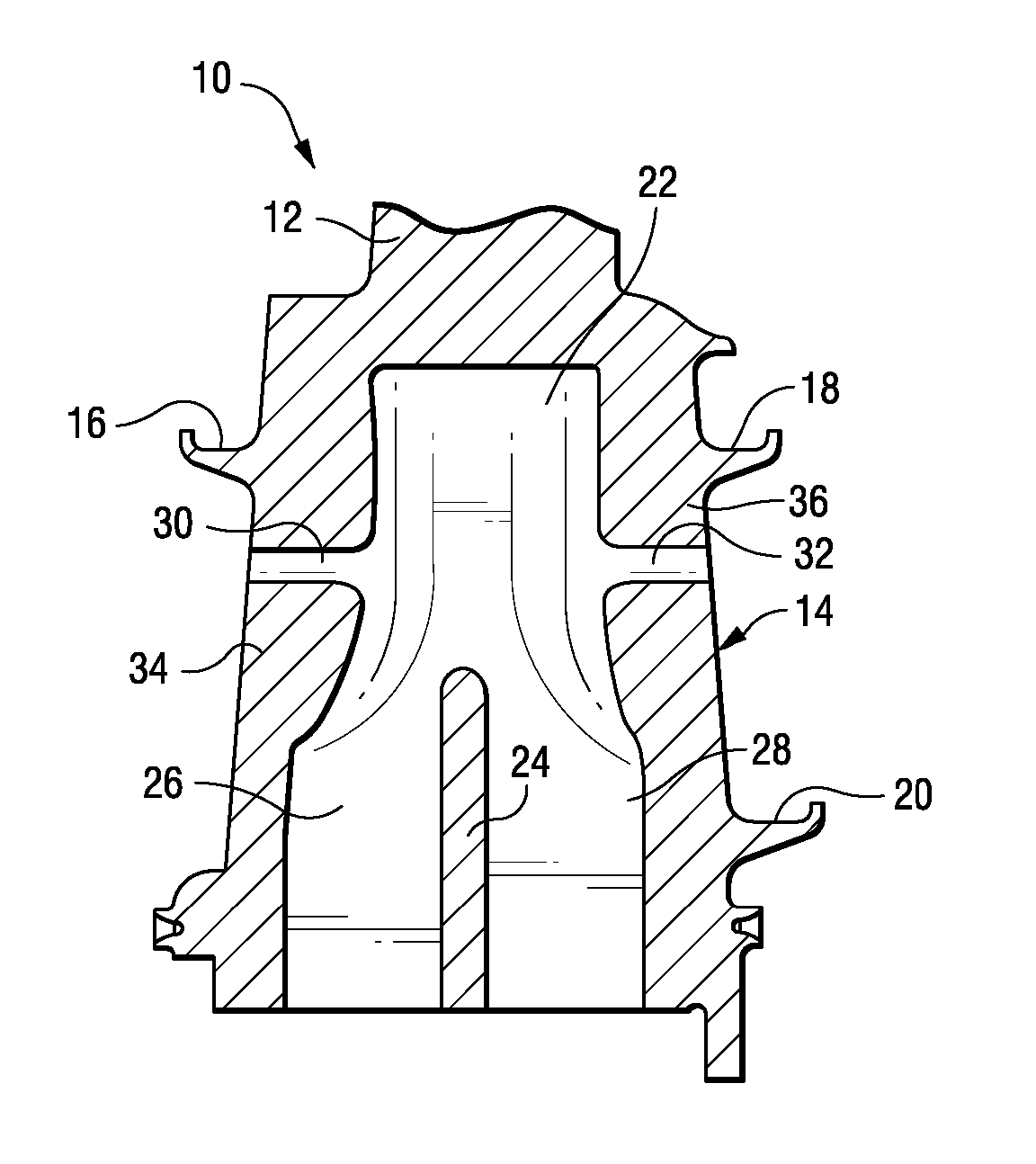

[0015] With reference to FIG. 1, a stage 1 turbine bucket 10 includes an airfoil portion 12 and a shank portion or shank 14. The shank includes a plurality of so-called angel wings 16, 18 and 20 that serve as seals vis-a-vis adjacent buckets when installed on the rotor wheel of a gas turbine. The interior of the shank portion includes a hollow space 22, with a central divider 24 that establishes side-by-side cooling passages 26 and 28. Elliptical holes 30 and 32 are cast in the fore and aft shank walls 34 and 36, respectively, as a byproduct of having the core supported in the shell die during casting.

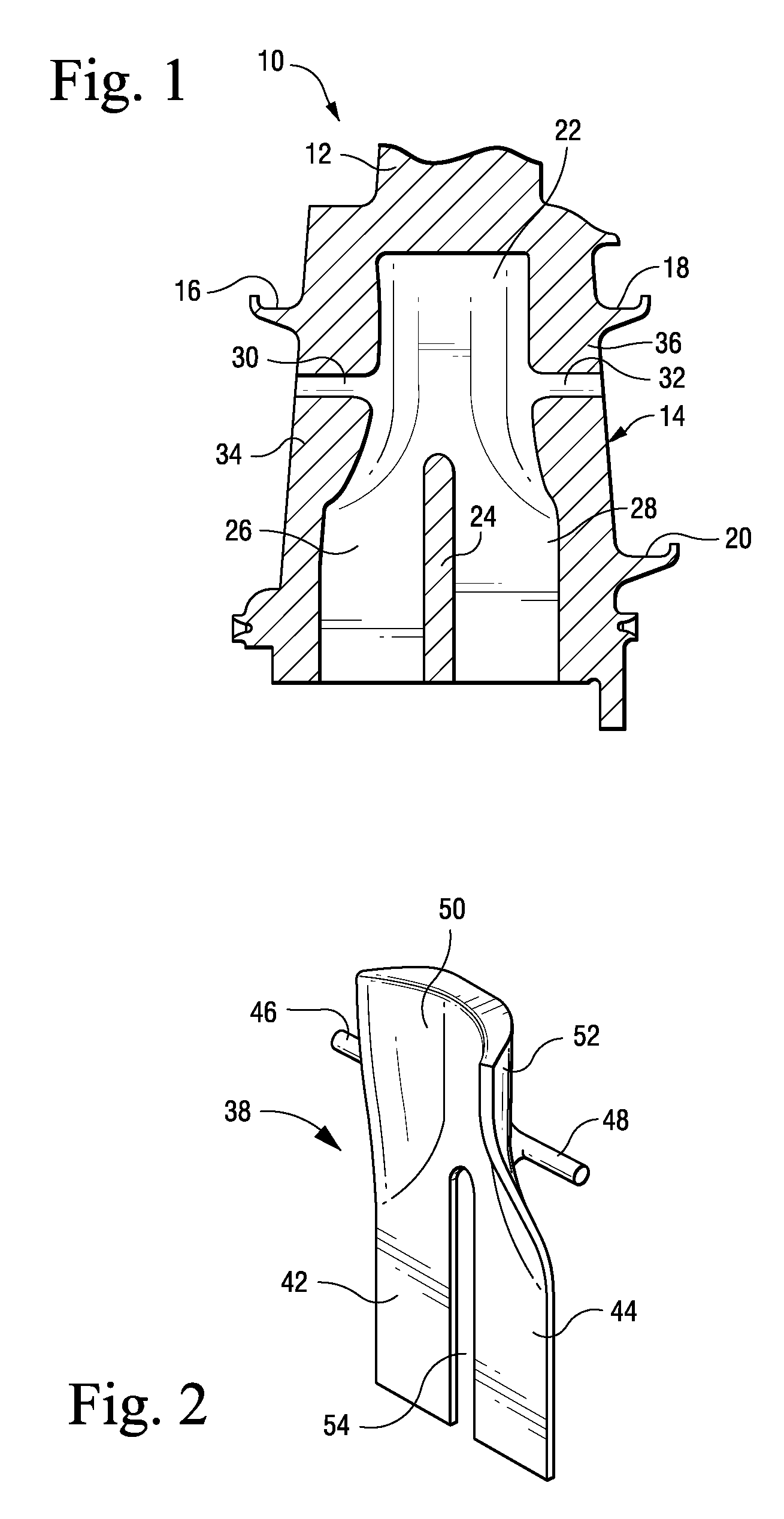

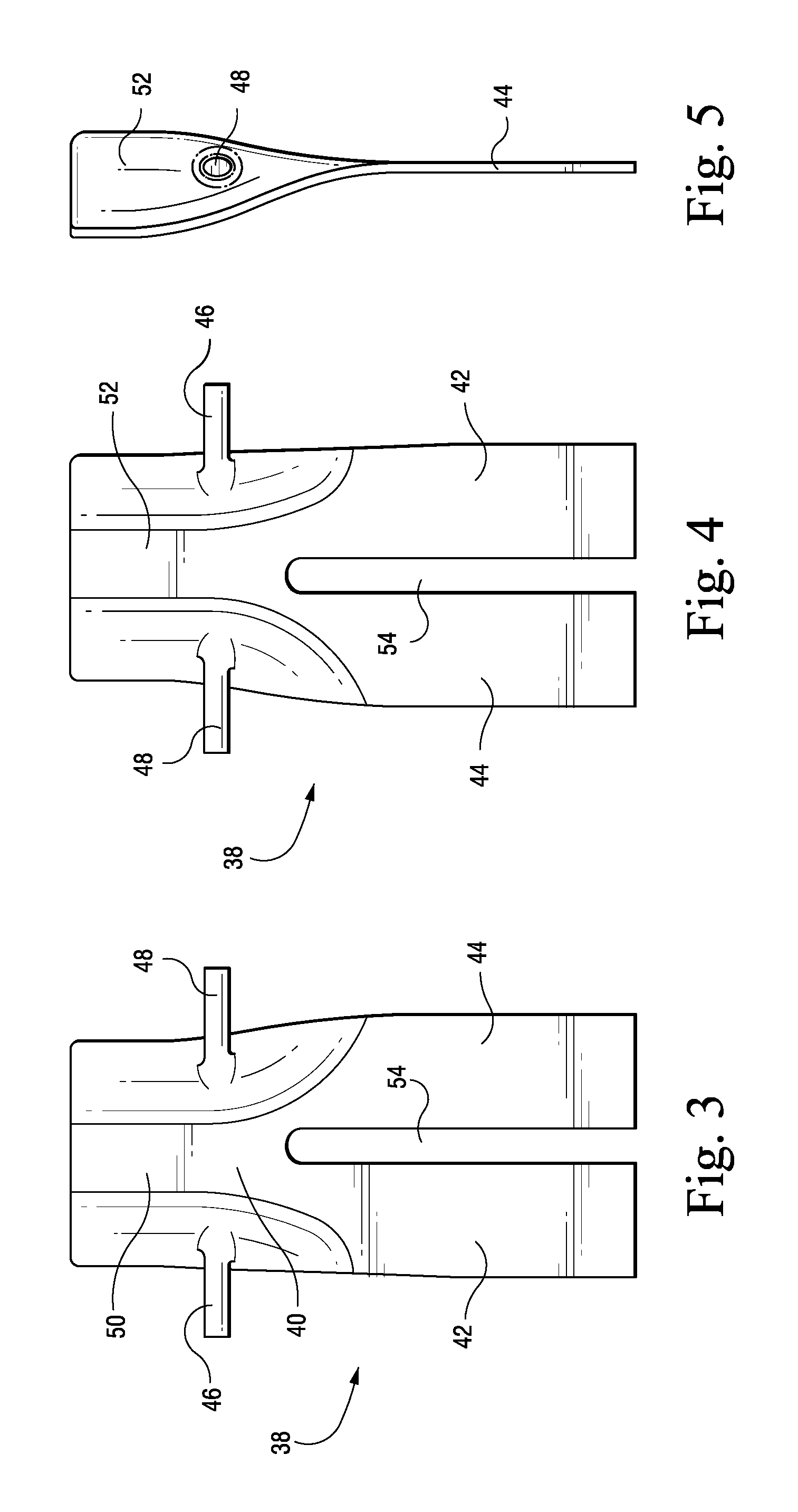

[0016] Turning to FIGS. 2-5, the core 38 has a generally “pants-leg” shape with a solid upper body portion 40 and a pair of radially inwardly extending legs 42 and 44 in accordance with an exemplary embodiment of the invention. A pair of stabilizing pegs or printouts 46, 48 extend axially from opposite sides of the core while an elongated radially extending slot 54 separates the pants...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com