Container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

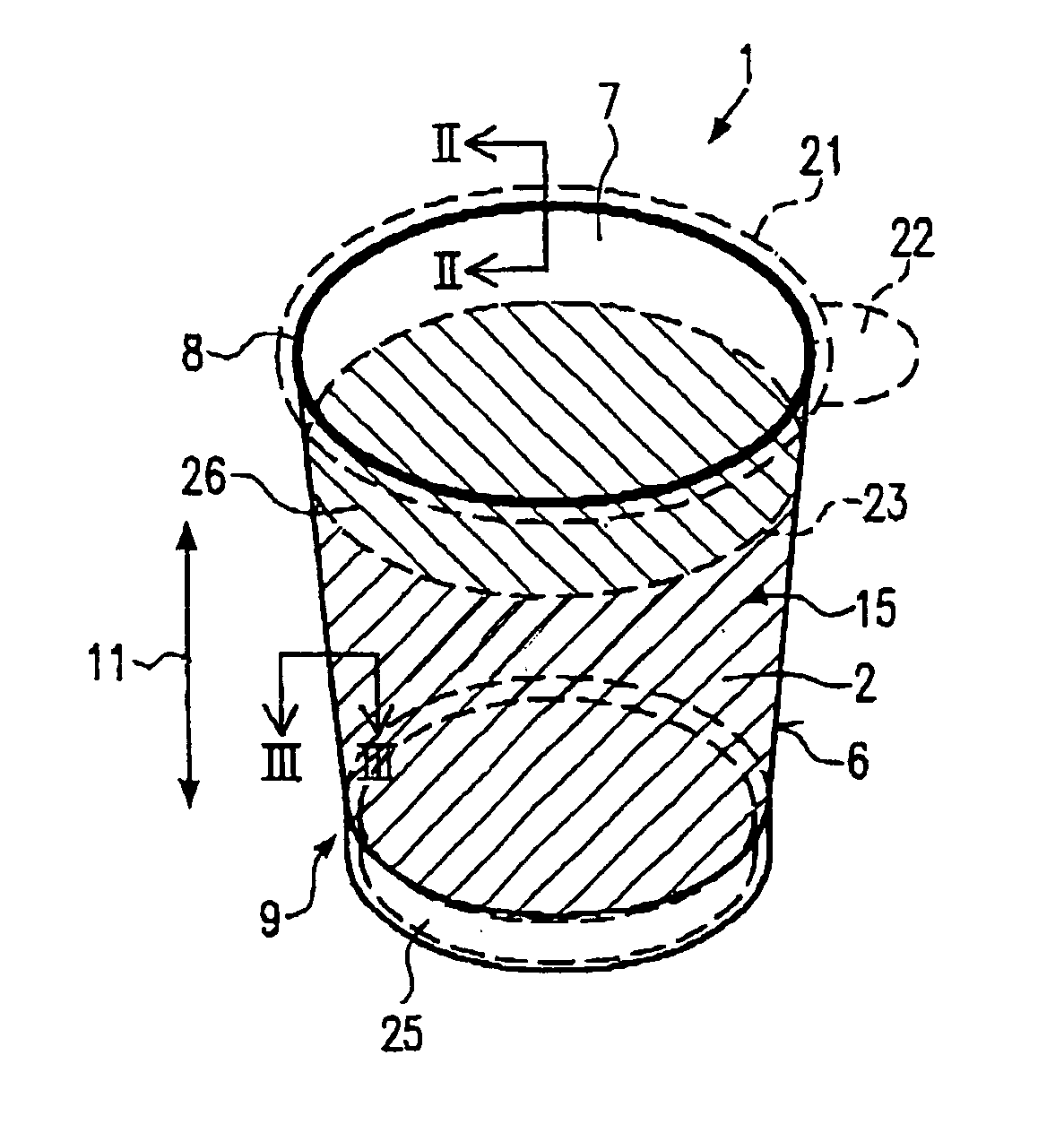

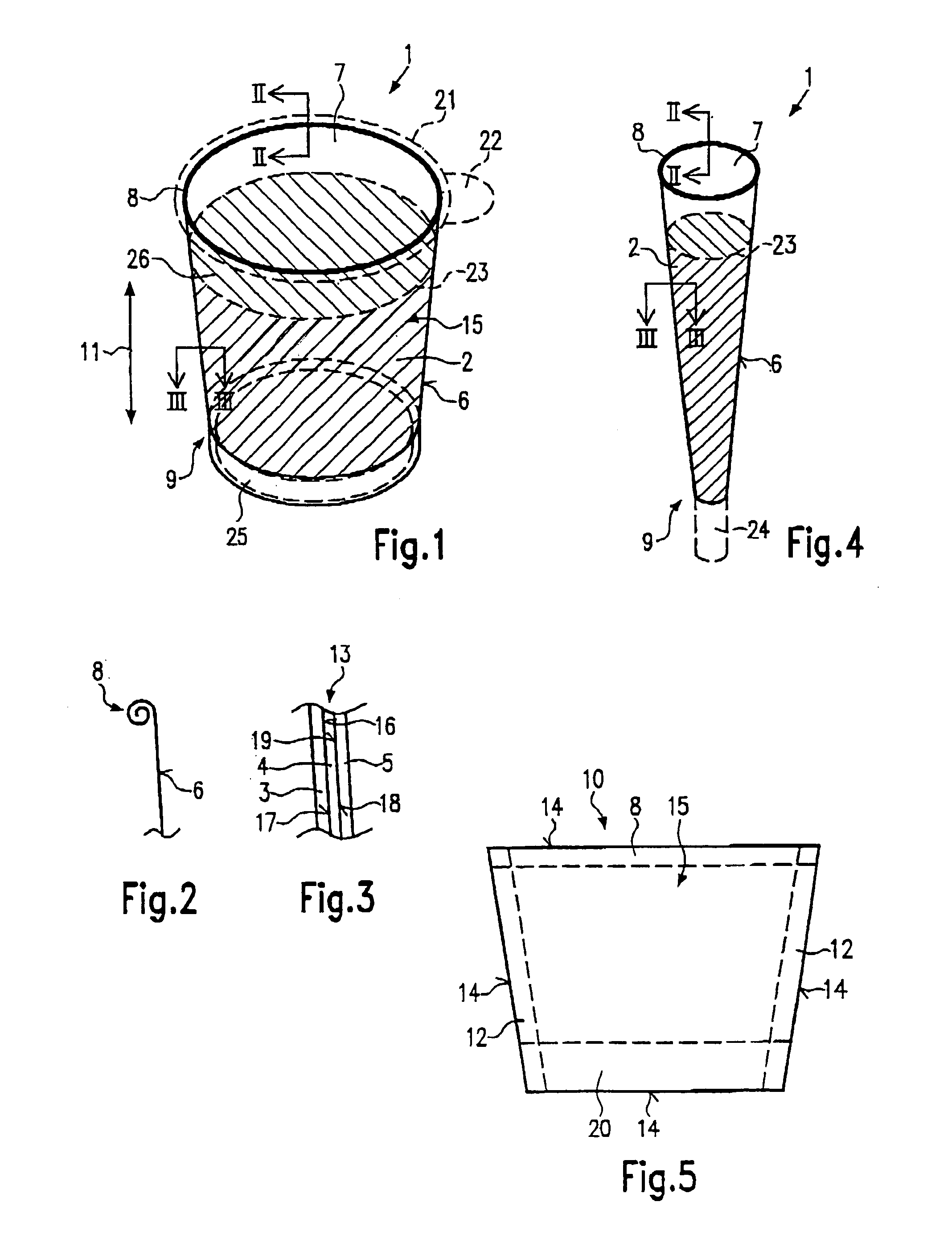

[0074]FIG. 1 shows a container 1 in a side view which has a cupulate design. Container 1 comprises a withdrawal opening 7 at its upper end in FIG. 1 which is surrounded by a rolled opening edge 8, also see FIG. 2.

[0075] A lid 21 is tightly attached to the opening edge 8. At least at one location, a lid handle 22 serving for drawing off the lid 21 from the opening edge 8 radially projects to the outside from the lid.

[0076] Food 2, which can be liquid, pasty, throwable or pourable, is filled in the interior of the container. The food 2 is filled in the container up to the filling level 23.

[0077] The container 1 comprises a container wall 6 which is formed by a blank according to FIG. 5. The container wall 6 is made of a transparent and fluid tight material.

[0078] In the embodiment according to FIG. 1, the container 1 comprises a bottom insert 25 at its end 9 opposite the withdrawal opening 7. The same is at least partially placed over or in the wall 6 from the outside and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com