Connector block for shock tubes and method of securing a detonator therein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

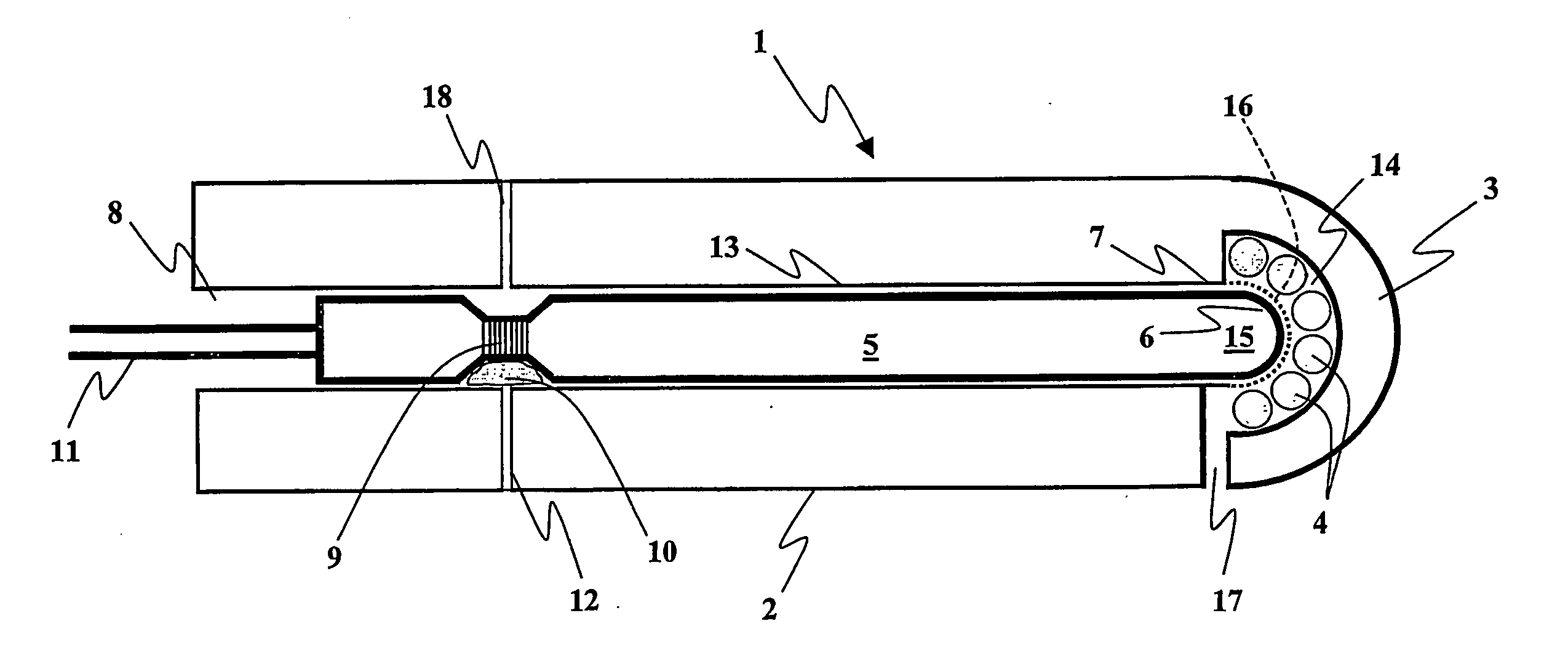

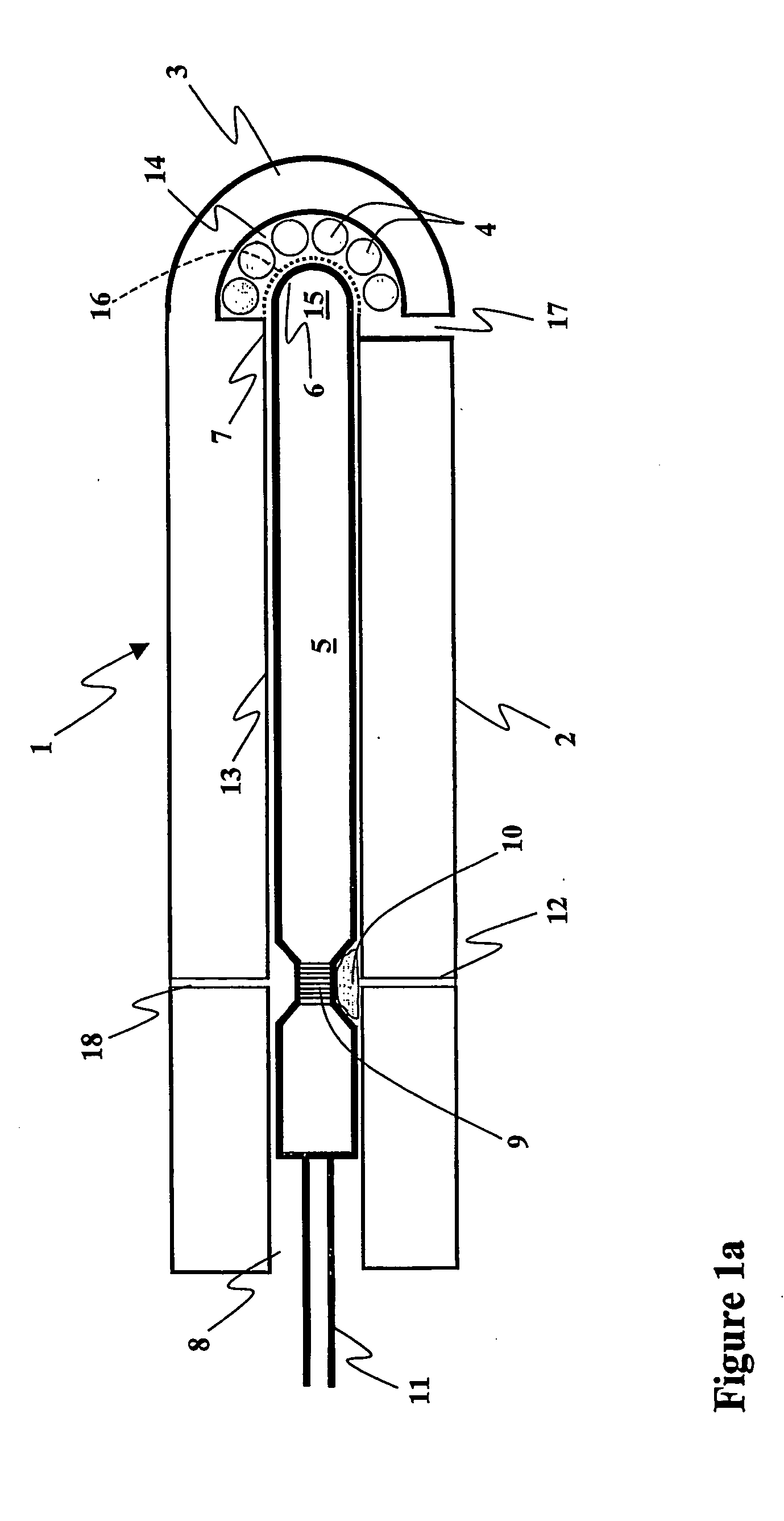

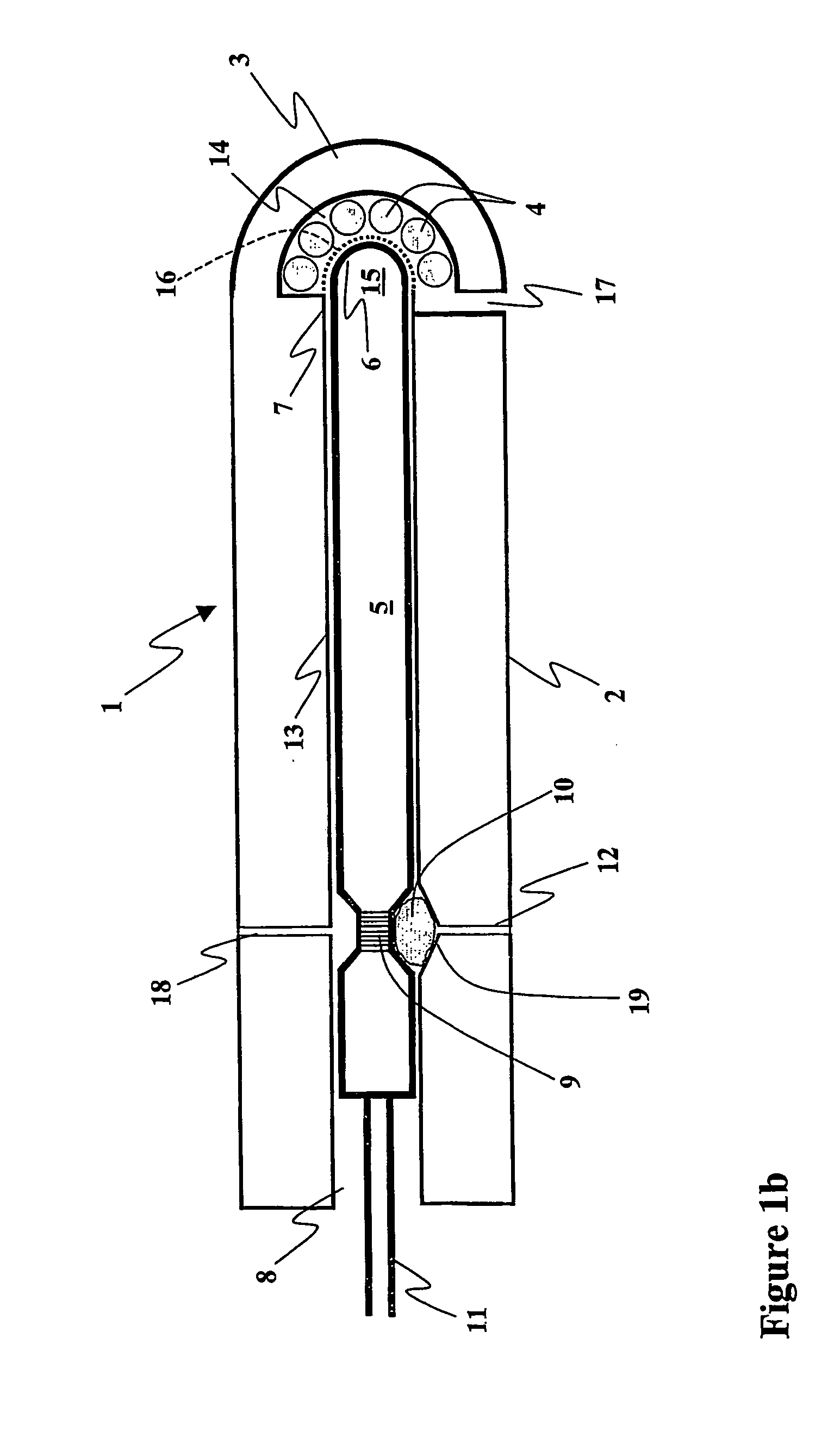

[0036] Preferred embodiments of the present invention are described in the following with reference to the accompanying drawings.

[0037]FIG. 1a illustrates a first preferred embodiment of the present invention, wherein a body of material in the form of a settable locking material is injected into the connector block to secure a detonator positioned therein. The connector block 1 is shown in longitudinal cross-section. The connector block comprises a housing 2, preferably made of a plastics material, with a cylindrical bore 13 running longitudinally through the housing. The bore 13 has an open end 8 and a signal transmission end 7.

[0038] While the bore 13 of all of the illustrated embodiments is formed as a cylindrical through hole, it will be appreciated by persons skilled in the art that the bore may alternatively be an open-sided slot or trough. However, a bore having a cross-section that is identical to, or closely approximates, that of a detonator to be used in the device, will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com