Support for a vehicle jack

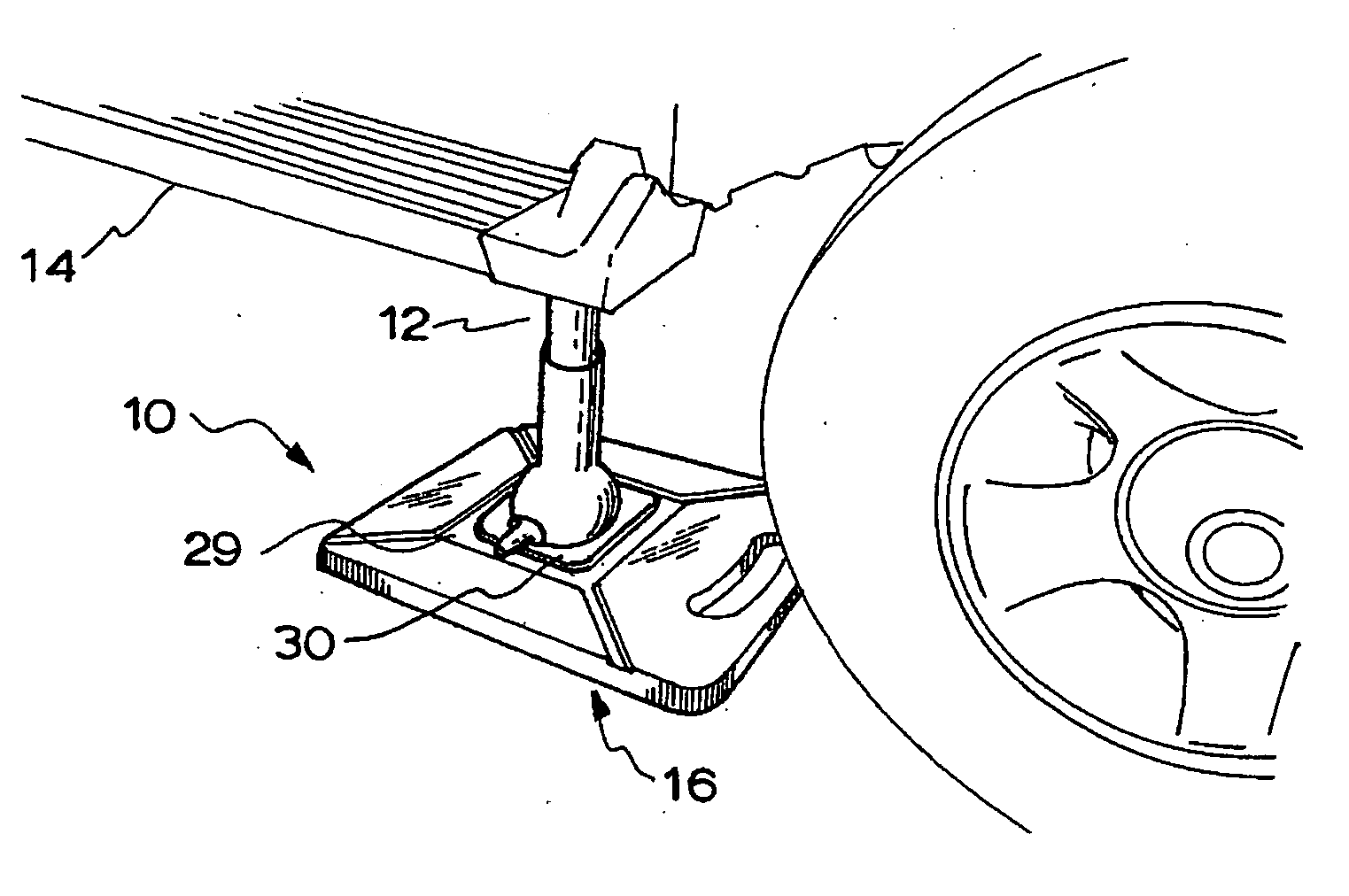

a vehicle jack and support technology, applied in the direction of inclined ship lifting, lifting devices, ship-lifting devices, etc., can solve the problems of vehicle jacks, especially, being susceptible to lateral/horizontal and/or vertical movement, and exacerbated problems, so as to improve the stability and/or safety of vehicle jack use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0048] In FIGS. 8 and 9, there is shown a support 68 according to the invention, wherein the holding means distinctly comprises a finger grip 70 made from an aperture that extends from the upper surface 72 to lower surface 74.

fourth embodiment

[0049] In FIGS. 10 and 11, there is shown a support 76 according to the invention, wherein the positioning of the holding means 78 in the support body is distinct.

fifth embodiment

[0050] In FIGS. 12 and 13, there is shown a support 80 according to the invention, wherein the positioning and size of the holding means in the form of a finger grip 82 is distinct again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com