Magnetic toner, and developing apparatus and image forming apparatus using it

a developing apparatus and toner technology, applied in the field of magnetic toner, can solve the problems of deterioration of the carrier, variability of the mixing ratio between the toner and the carrier, and the development of the toner with a magnetic toner, and achieve the effect of less fogging and less reddish images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

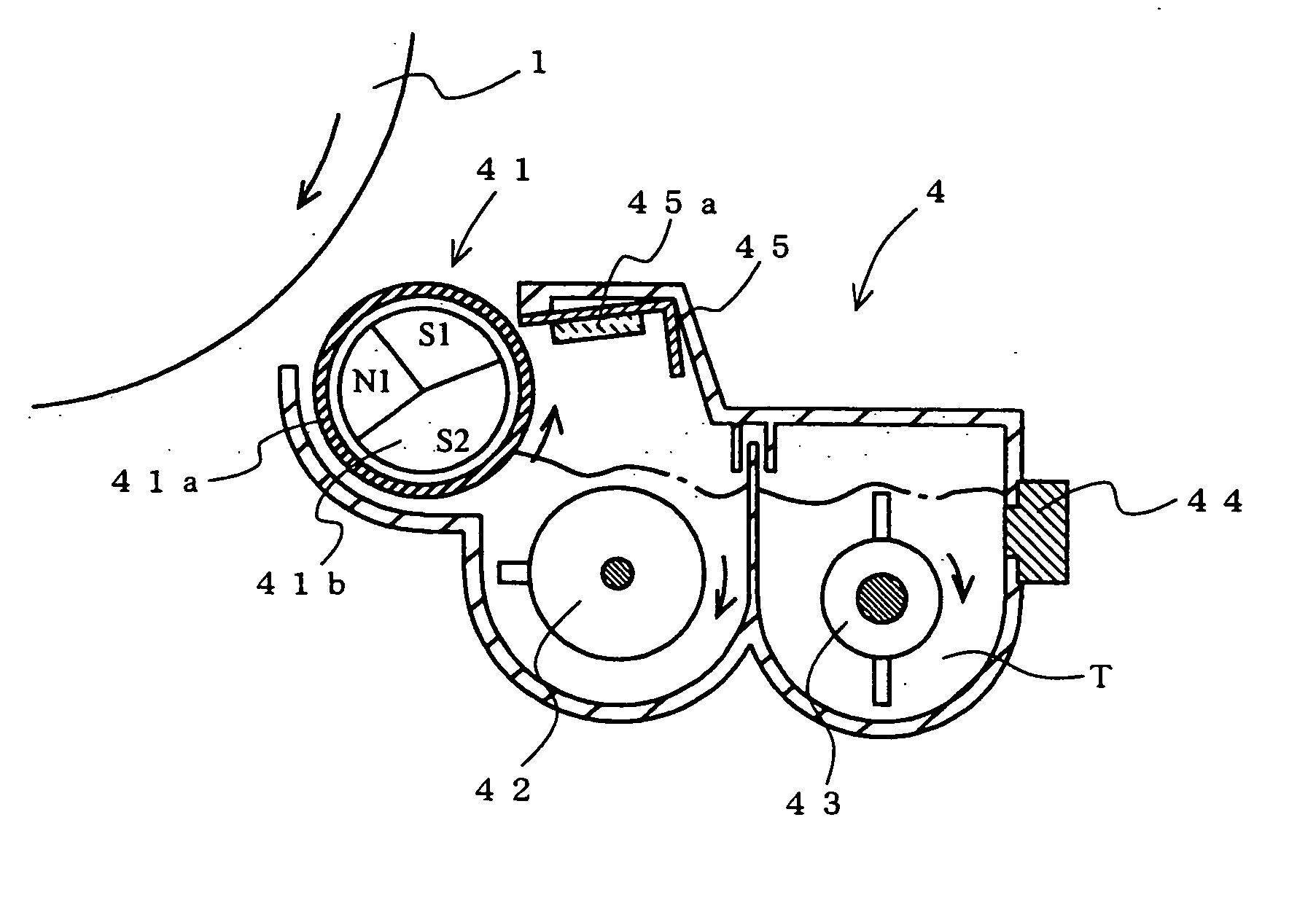

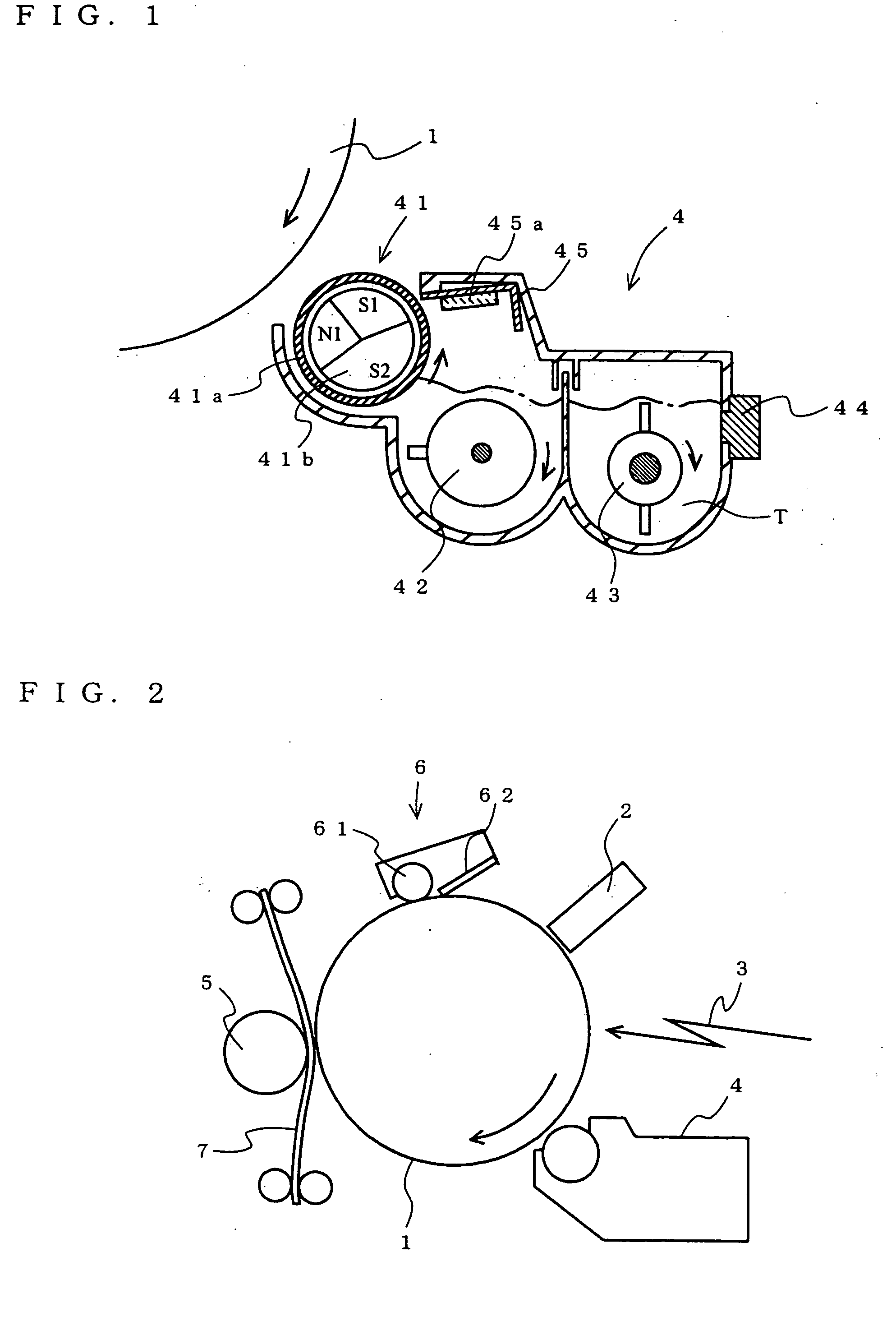

Image

Examples

example 1

Practical Example 1

Toner ingredients, specifically 100 parts by weight of styrene-acrylic resin serving as a binder resin, 5 parts by weight of a charge control agent, and 40 parts by weight of a magnetic powder (having an octahedral particle shape and an average particle diameter of 0.25 μm and containing 18% by weight of FeO), were put and mixed in a Henschel mixer, were then melt-kneaded in a twin-screw extruder, were then cooled in a drum flaker, and were then coarsely crushed on a hammer mill. The resultant granules were then finely crushed on a mechanical mill, and were then classified with a pneumatic classifier to obtain toner particles with a predetermined volume average particle diameter. These toner particles were blended with 0.6% by weight of silica (with a particle diameter of 0.012 μm), and were mixed through intense agitation in a Henschel mixer to obtain a magnetic toner that tends to be charged positively.

The bulk density of this magnetic toner was measured in t...

examples 2 to 7

Practical Examples 2 to 7 and Comparative Examples 1 to 8

With toners prepared so as to contain different types of magnetic powder and have different bulk densities as shown in Table 1, images produced with them were evaluated in the same manner as with Practical Example 1.

Table 1 shows the following. With the magnetic toners of Practical Examples 1 to 7, which are magnetic toners according to the present invention, image reddishness was alleviated to such a degree as to be ignorable in practical terms, and no background or partial fogging was observed. Nor was observed inadequate initial image density under high-temperature, high-humidity conditions. Moreover, with any of these magnetic toners, an image density of 1.3 was sustained after bulk printing on 10,000 sheets. With the magnetic toners of Practical Examples 1 to 4 and 6, an image density of 1.3 was sustained after bulk printing on 20,000 sheets. By contrast, with the magnetic toners of Comparative Examples 1 and 2, which ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap