Mobile container

a container and torsional rigidity technology, applied in the field of mobile containers, can solve the problems of reducing the interior volume, limiting standard transportation, and reducing the torsional rigidity of the entire container, and achieve the effect of increasing the torsional rigidity of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

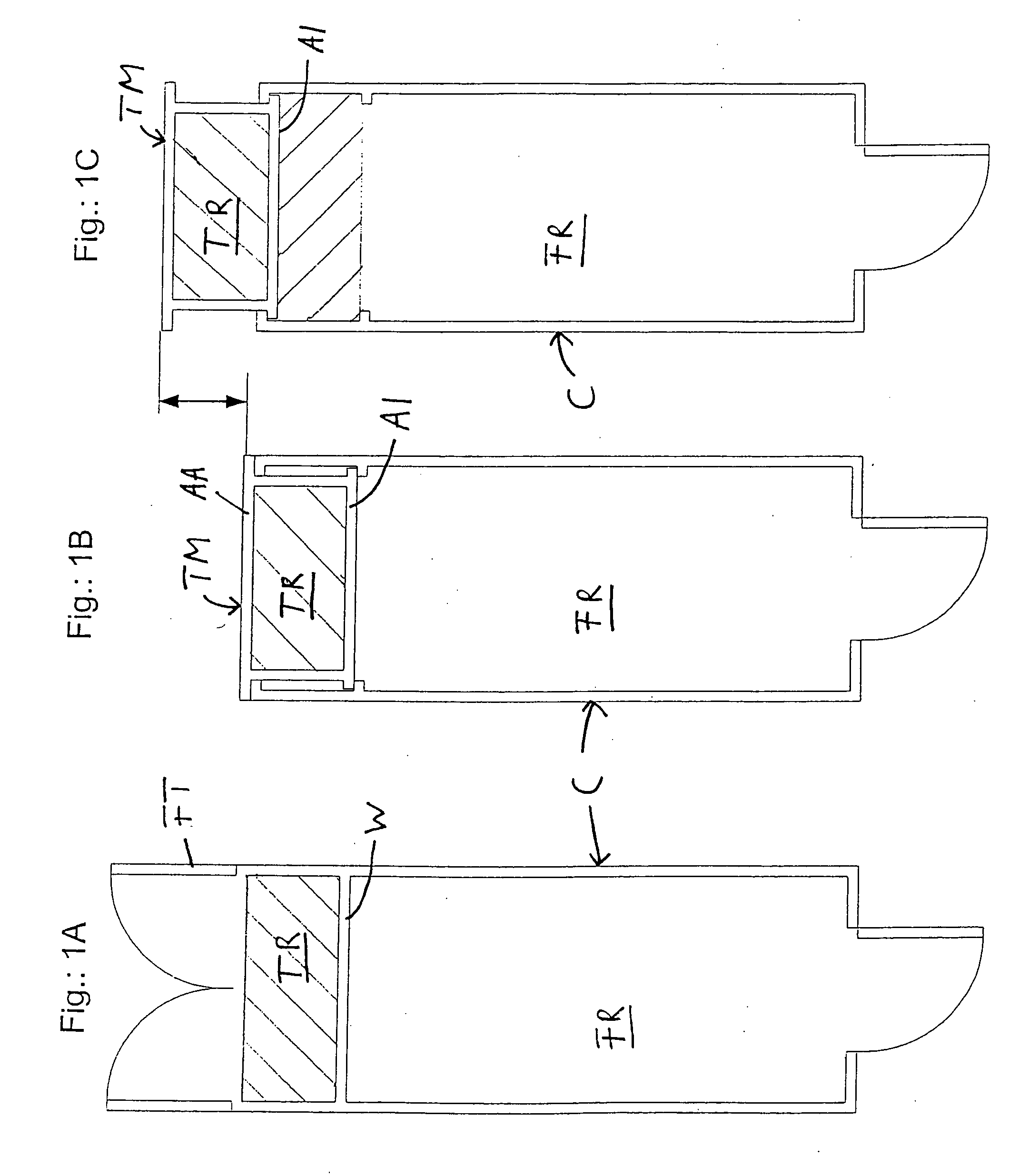

[0024]FIG. 1A shows a standard 20′ prior art container C with an internal, fixed partition W between the technical space TR and the functional space FR. The technical space TR reduces the functional space FR. The additionally required external access door FT configured as a double door for the technical space TR decreases the rigidity of the container C, particularly during transport. The internal partition W, on the other hand, increases the rigidity.

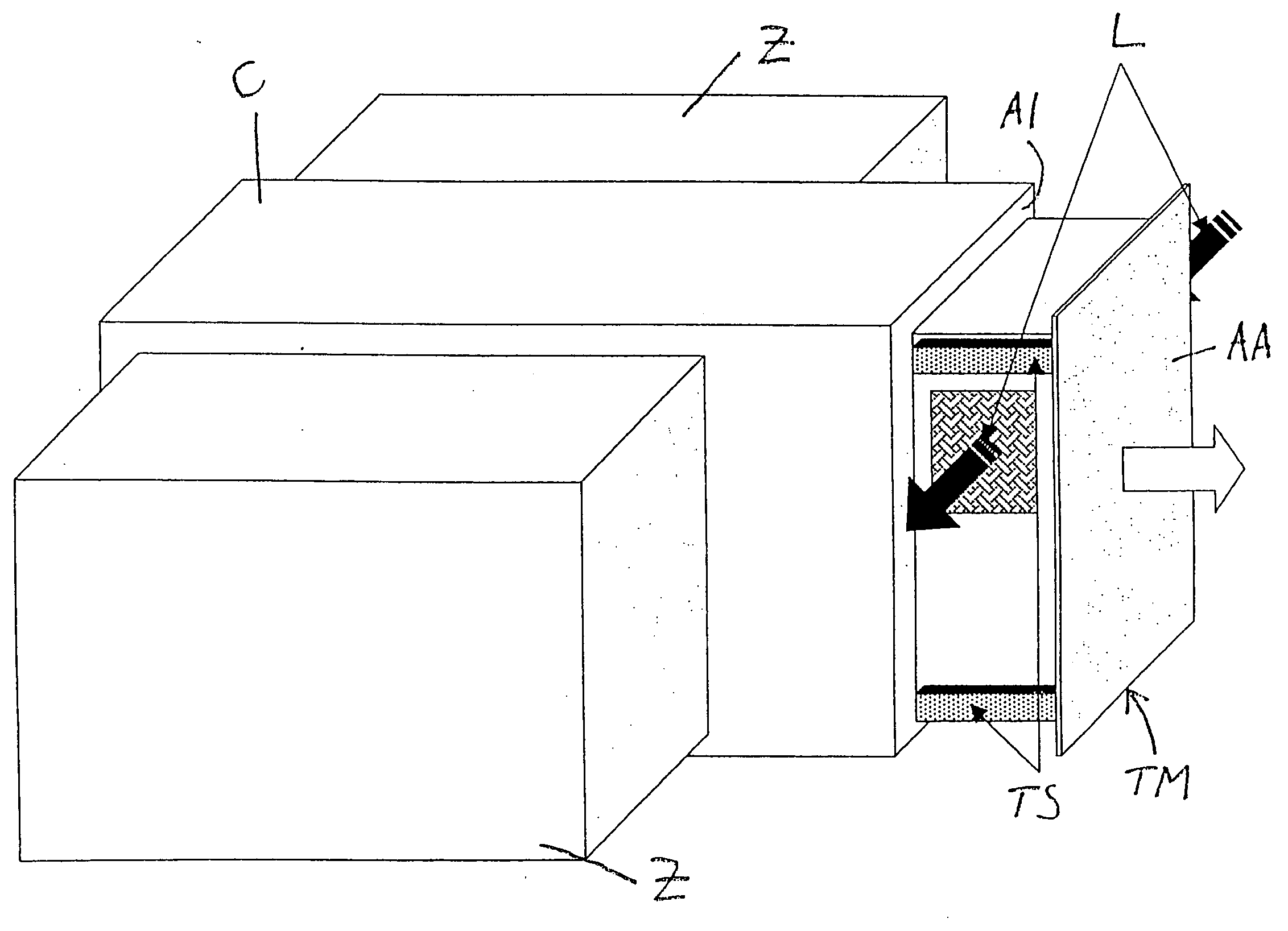

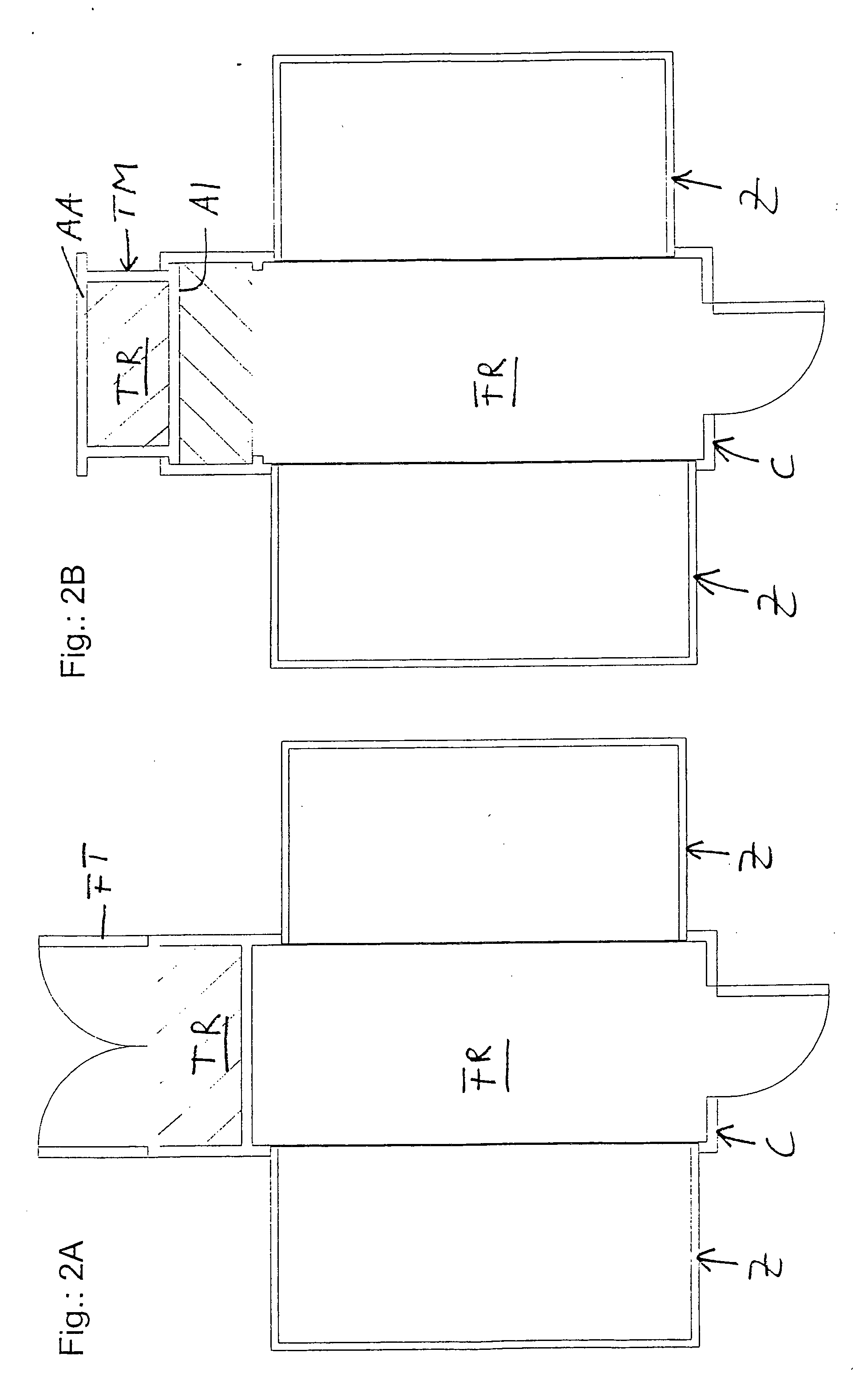

[0025]FIG. 1B shows a container C according to the invention, based on a standard 20′ container, in its transport configuration, i.e., with completely retracted technical module TM. In this embodiment the technical module TM is arranged on the transverse side of the container C and is displaceable in the longitudinal direction. In this position, the volume of the functional space FR corresponds to the volume of the container C shown in FIG. 1A. Both closing plates AA, A1 of the technical module TM are bolted to the container. This inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com