Multi-stage eductor apparatus

a multi-stage, eductor technology, applied in mechanical equipment, machines/engines, transportation and packaging, etc., can solve problems such as substantial performance reduction, and achieve the effect of effective us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

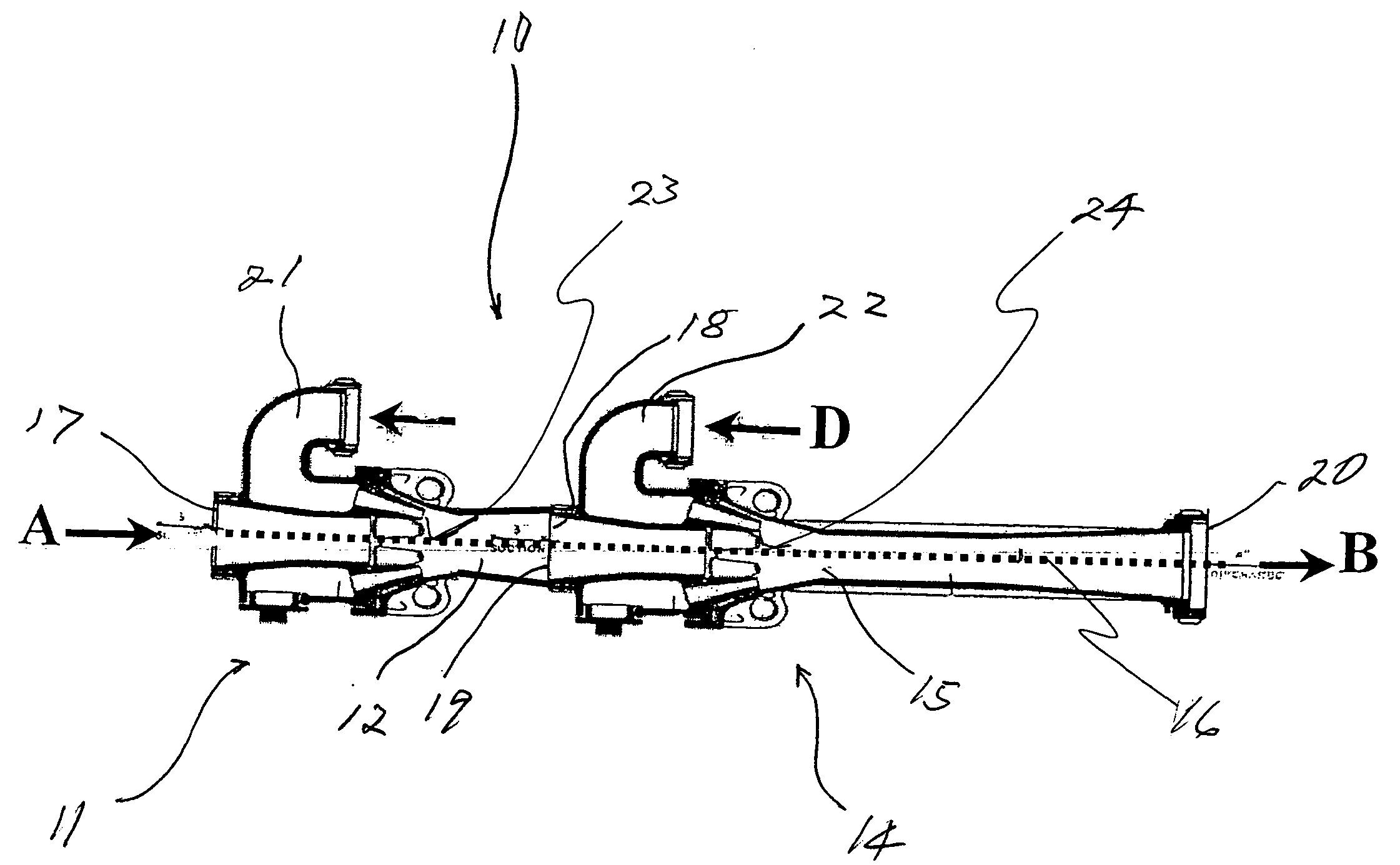

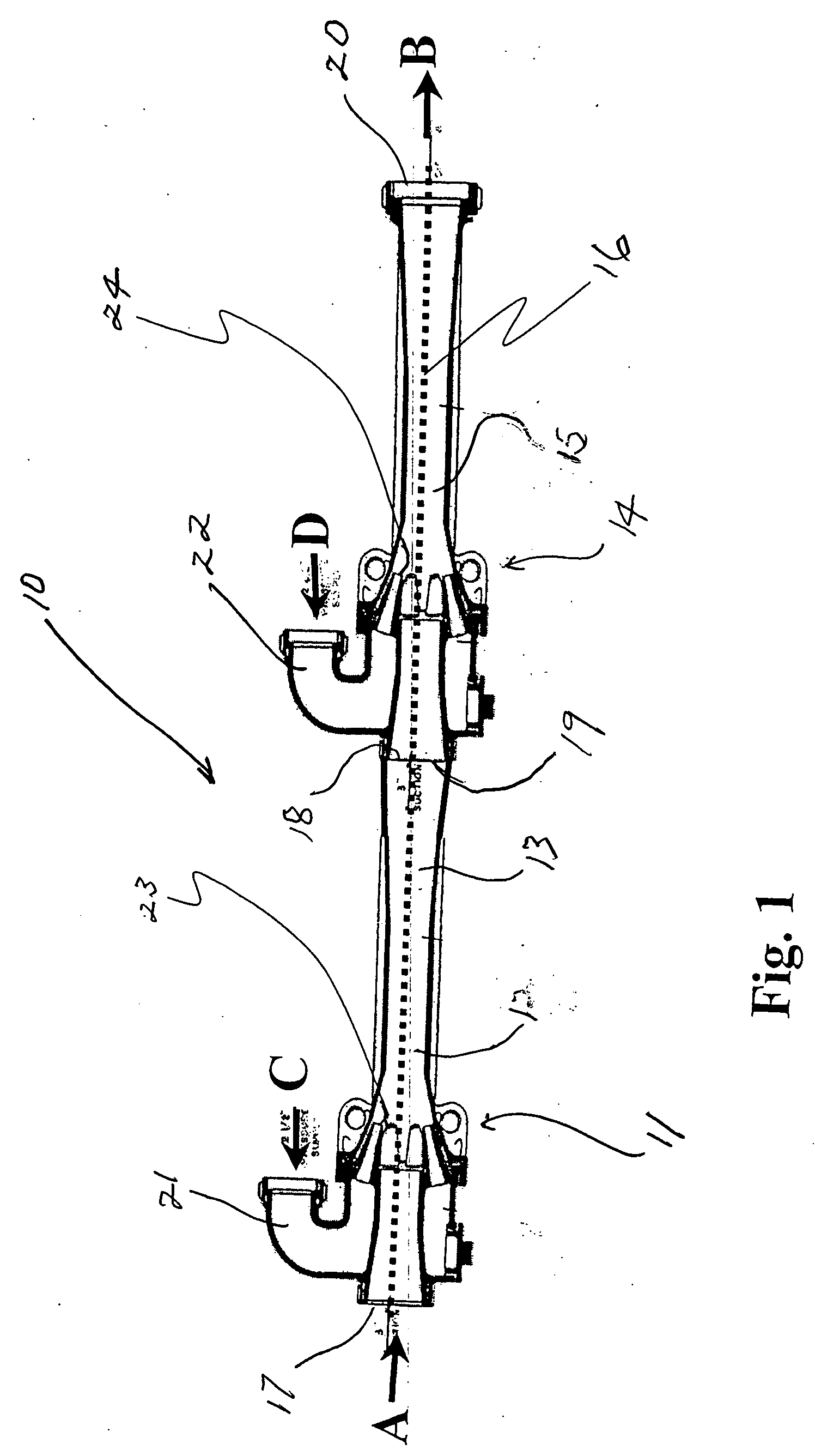

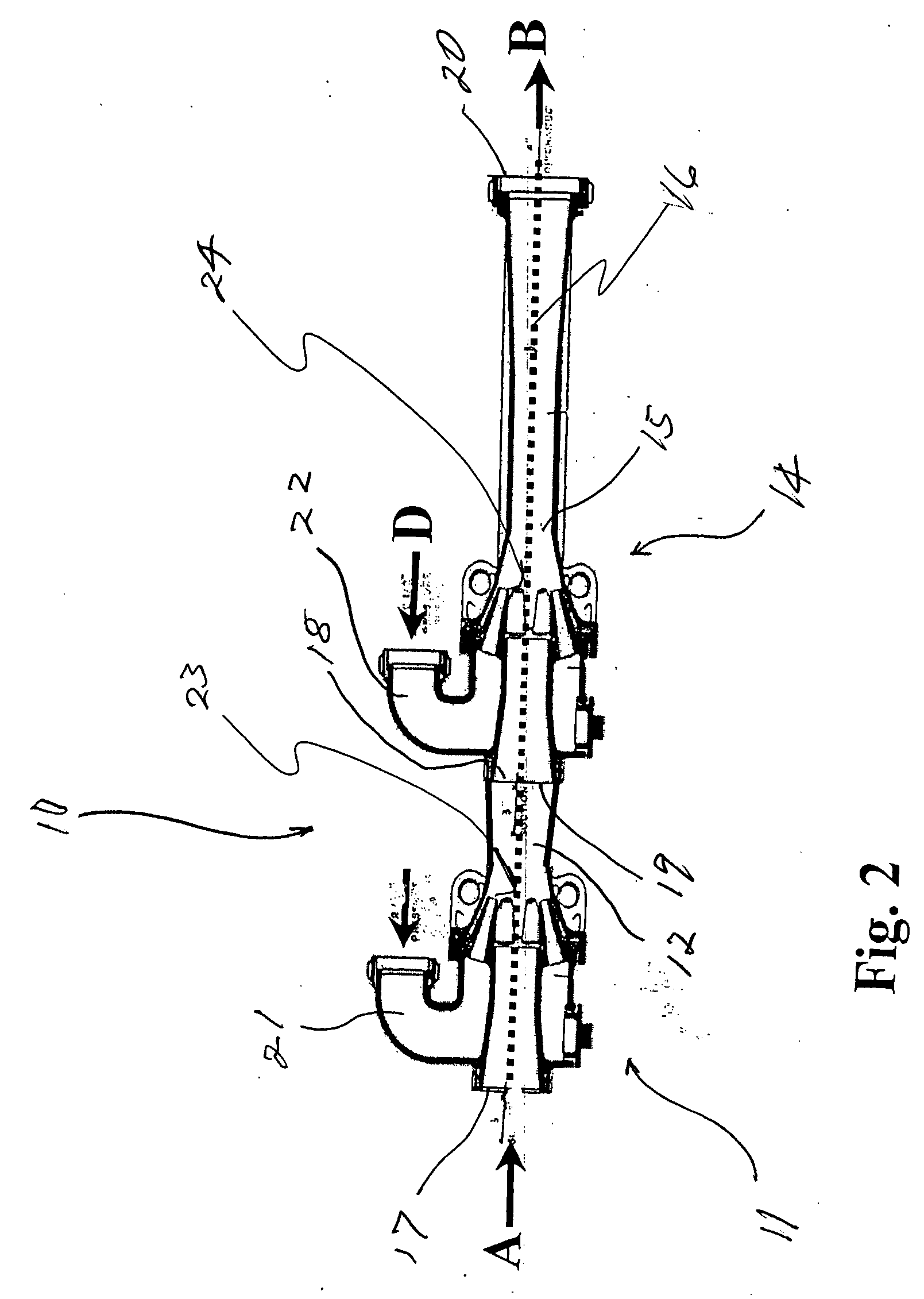

The multi-stage eductor of the invention, generally identified by reference number 10, comprises a first stage venturi-type eductor 11, with a venturi throat section 12 and a diffuser section 13, and a second stage venturi-type eductor 14 with a venturi throat section 15 and a diffuser section 16, connected in series with the first stage. The first stage eductor has an inlet 17 and an outlet 18, and the second stage eductor has an inlet 19 and an outlet 20. The inlet of the second stage structure connected to the outlet of the first stage so that the longitudinal axes of the first and second stages are in coaxial alignment. The flow of material into the multi-stage eductor apparatus is indicated as “A”, and the flow of material from the multi-stage eductor apparatus is indicated as “B”. The dashed line through the structure represents the longitudinal axis of the multi-stage eductor, as well as the center line of the flow path of material drawn into and through the eductor.

The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com