Air gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

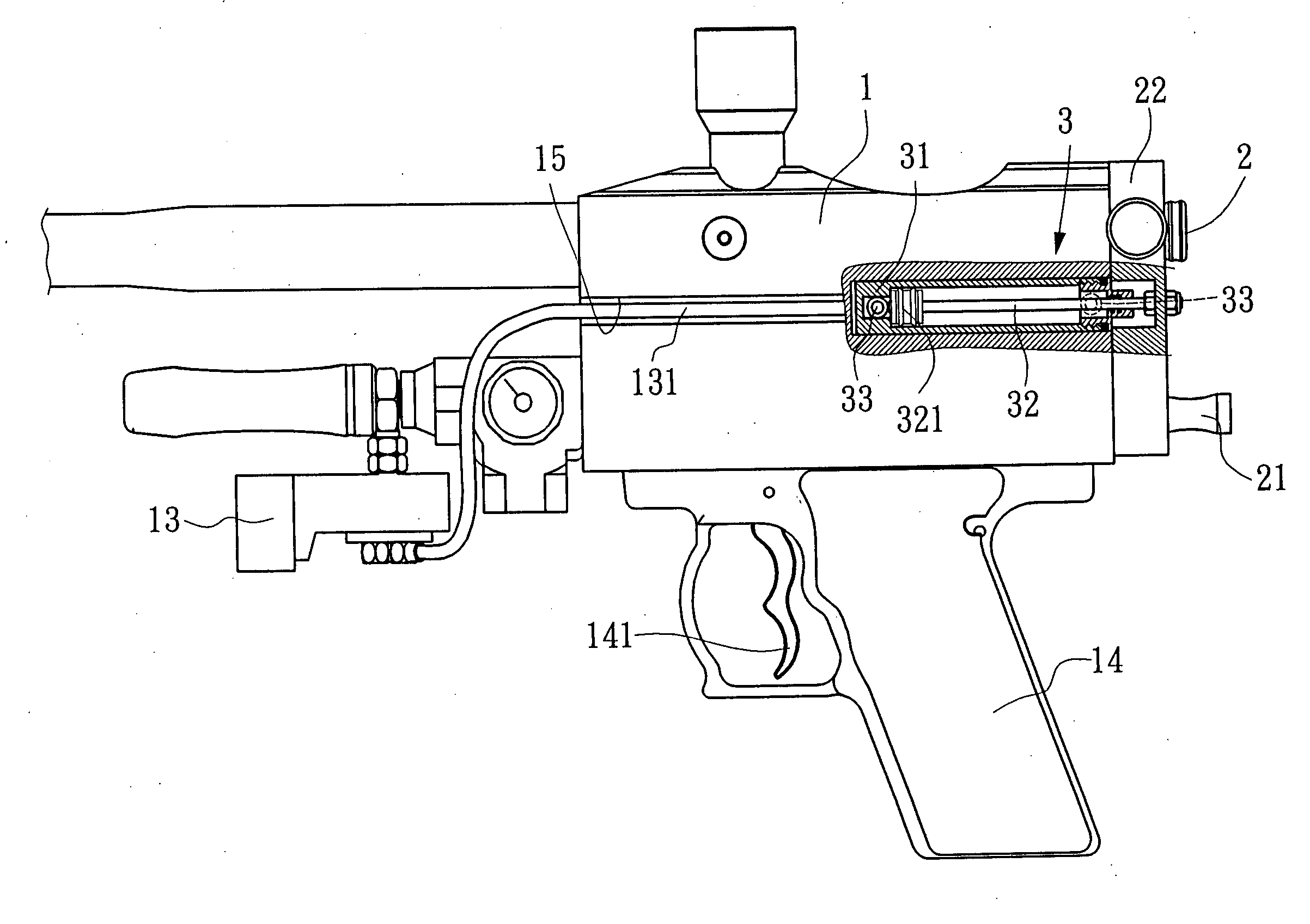

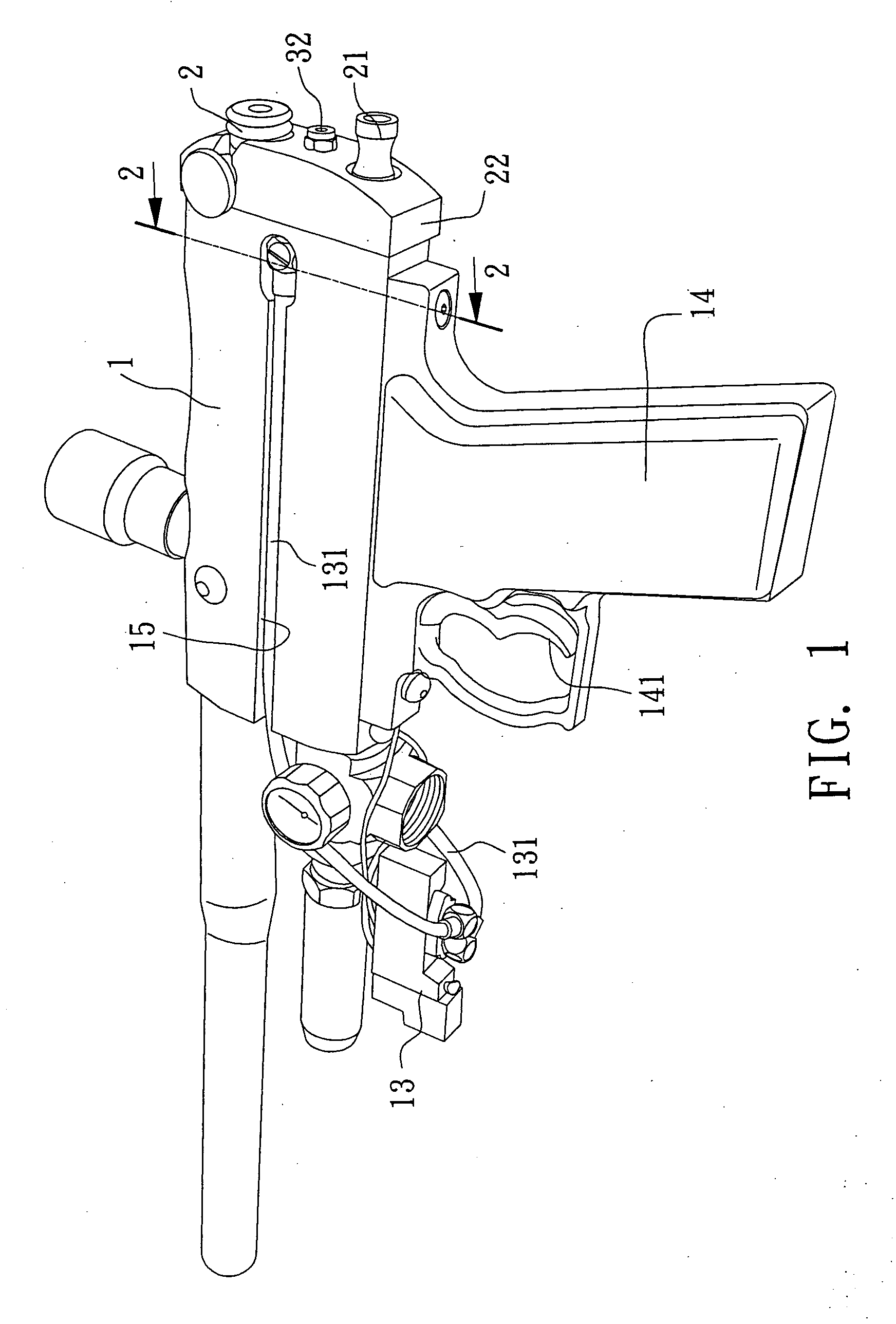

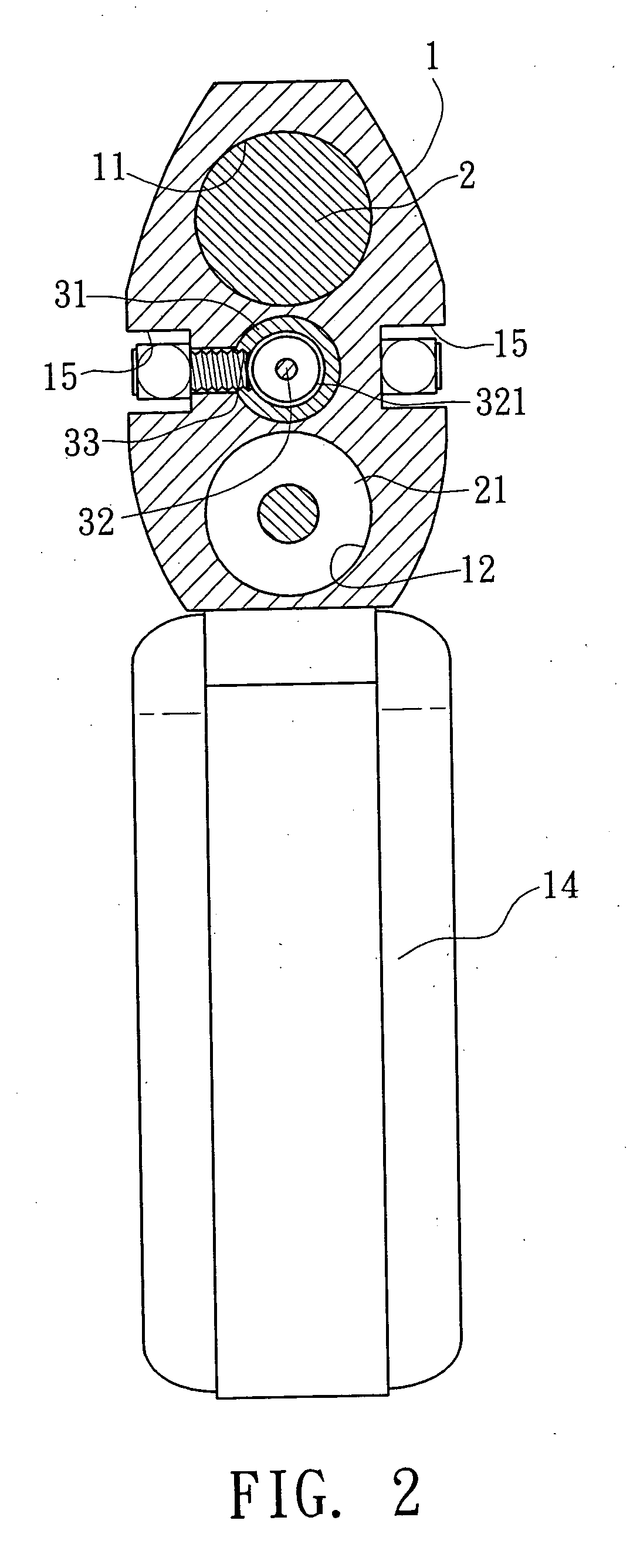

[0025]FIG. 6 shows the present invention, in which the thruster 3 has an air chamber 34 directly formed in the main body 1 right in alignment with the center of the rear block 22. The thruster 3 includes a piston rod 32 disposed in the air chamber 34. The air chamber 34 is positioned between the upper and lower air chambers 11, 12 of the main body 1. One end of the piston rod 32 positioned in the air chamber 34 has a piston 321. The other end of the piston rod 32 extending out of the air chamber 34 is right fixedly connected with the center of the rear block 22. Two ends of the air chamber 34 are respectively formed with two vents 33 for connecting with the pipelines 131 of the controlling valve 13.

first embodiment

[0026] The air chamber 34 is directly formed in the main body 1 instead of the cylinder 31. This can achieve the same effect as the first embodiment and the components of the air gun are simplified.

third embodiment

[0027] In the above embodiments, the pipelines 131 of the controlling valve 13 extend along the channels 15 of two sides of the main body 1 to connect with the vents 33 of the thruster 3. Alternatively, two passages 16 can be directly formed in the main body 1 as shown in FIG. 7 which shows the present invention. One end of each passage 16 is connected with the vent 33, while the other end of the passage 16 is connected with the pipeline 131 of the controlling valve 13. Accordingly, the air can be also conducted into the thruster 3 for driving the piston rod 32. Furthermore, the passages 16 are hidden in the main body 1 so that the appearance of the main body 1 is beautified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com