Golfing putter

a technology of golf putter and ball, which is applied in the field of golfing putter, can solve the problems and achieves the effect of reducing the predictability of the direction and distance traveled by the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

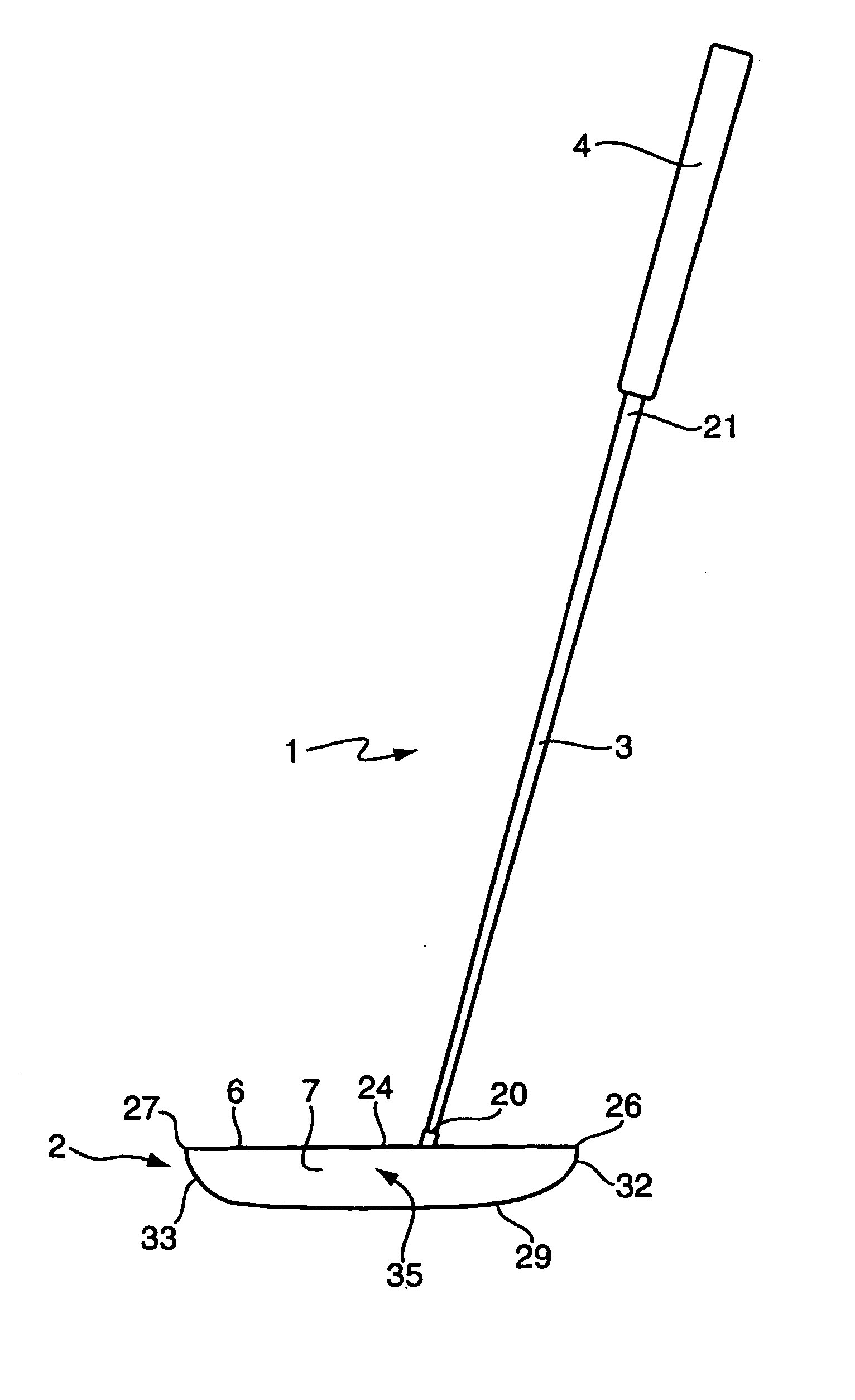

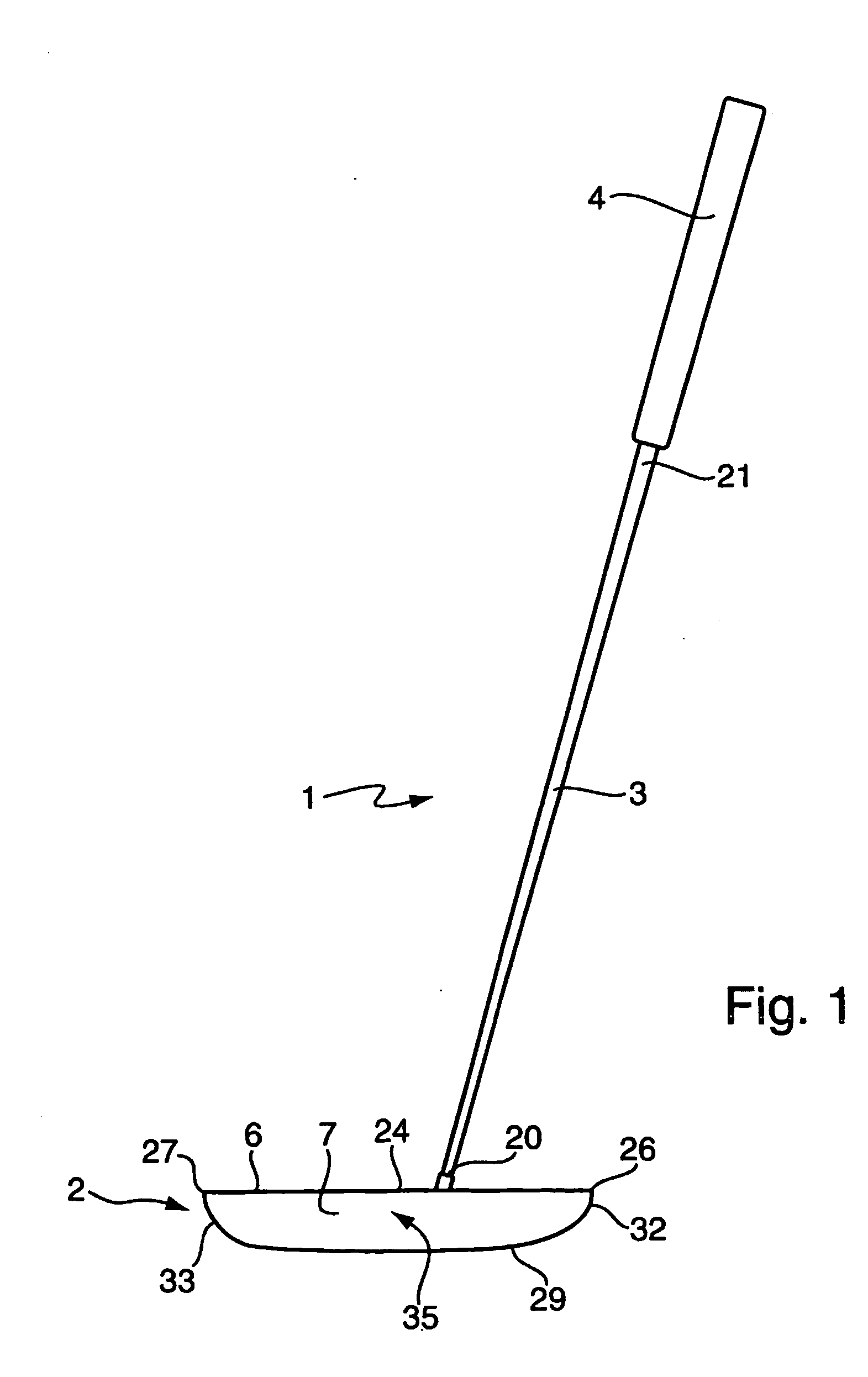

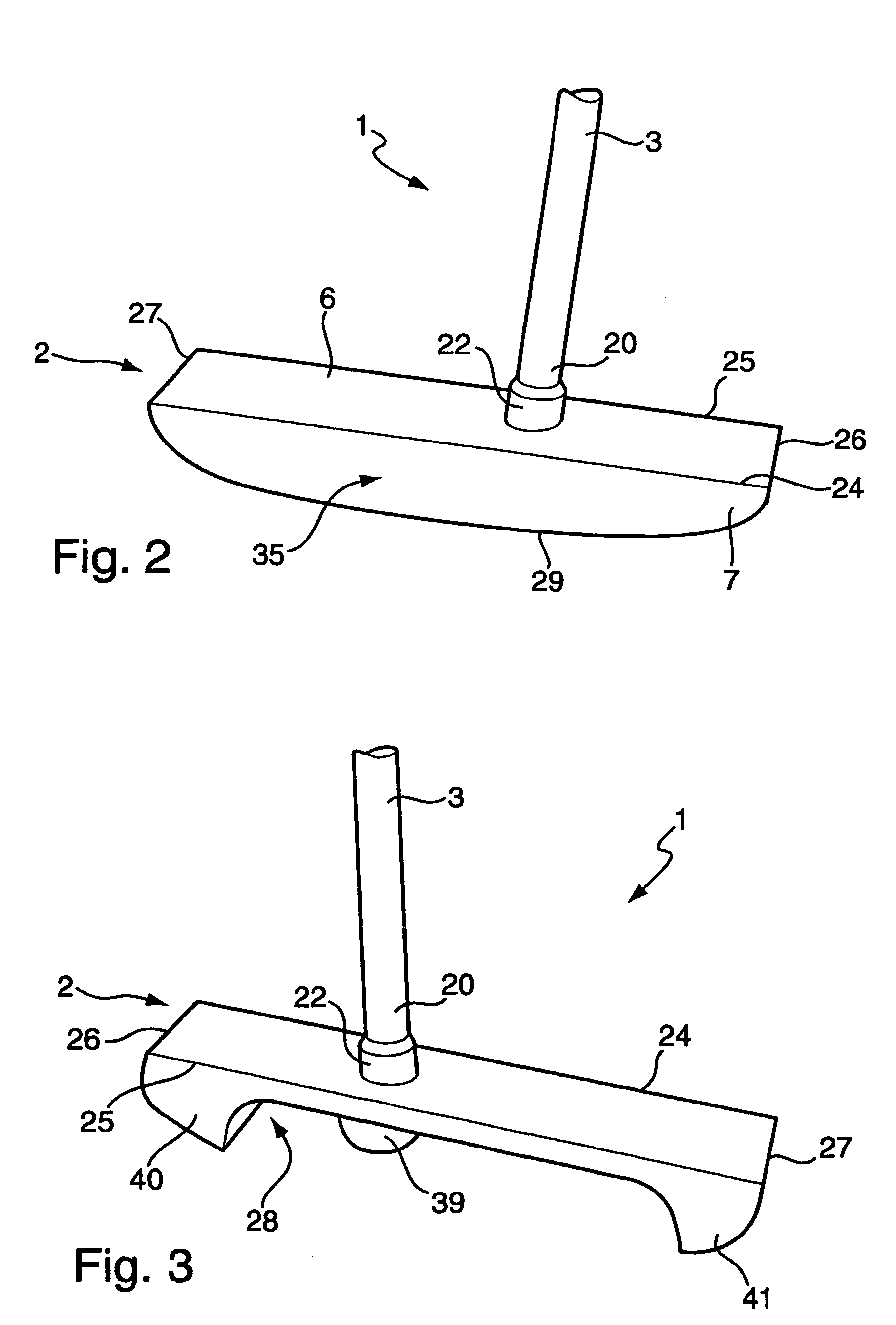

[0037]FIGS. 1, 2 and 3 show a first embodiment of a golfing putter 1. The putter 1 has a tapered chromed steel shaft 3 and a brass putting head 2. A narrow end 20 of the shaft 4 is attached to the brass putting head 2. An opposite wider end 21 of the shaft 3 passes inside a rubber hand grip 4. The shaft 3 and grip 4 are similar to those used for other golfing putters.

[0038] As shown in FIG. 2, the head 2 has a hole 5 into which the narrow end 20 of the shaft 3 is fitted, for example using an interference fit. Optionally, a chromed steel bushing 22 may surround the narrow end 20 of the shaft 3 to make a more secure fit to the hole 5. The shaft 3 may be bonded to the putting head 2 within the hole 5 or bushing 22 by an epoxy resin (not shown).

[0039] The putting head 2 has a rectangular flat top face 6. The shaft 3 is shown at an angle of 15° degrees to a normal of the top face 6 of the putting head 2, but may be between 10° and 45°.

[0040] The top face 6 is bounded by straight paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com