Noise absorbing structure and noise absorbing/insulating structure

a technology of noise absorption and noise insulation, applied in the direction of instruments, flooring, transportation and packaging, etc., can solve the problem that the noise absorption effect based on the helmholtz resonance principle cannot be shown sufficiently, and achieve the effect of effective noise absorption and wide frequency rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

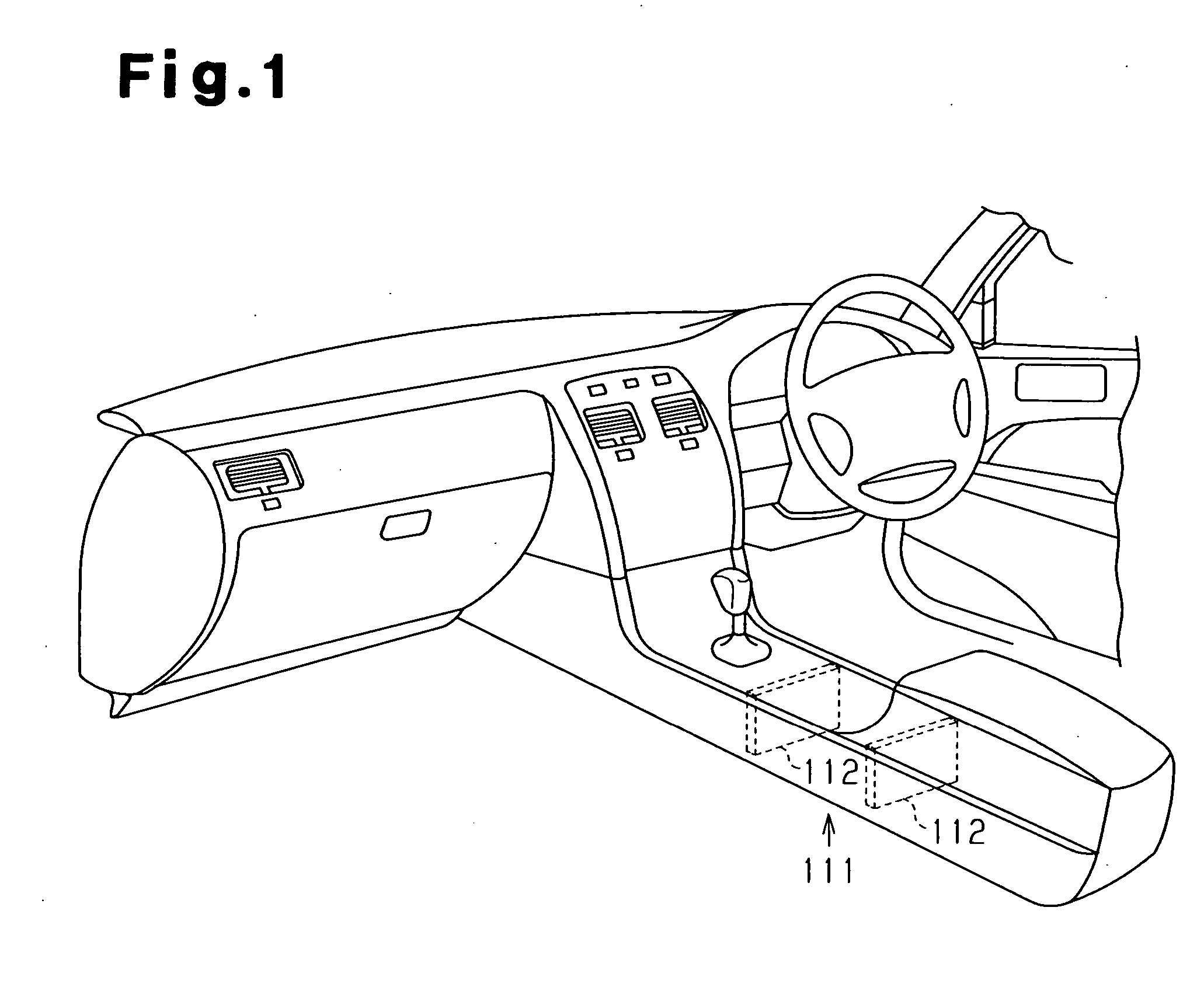

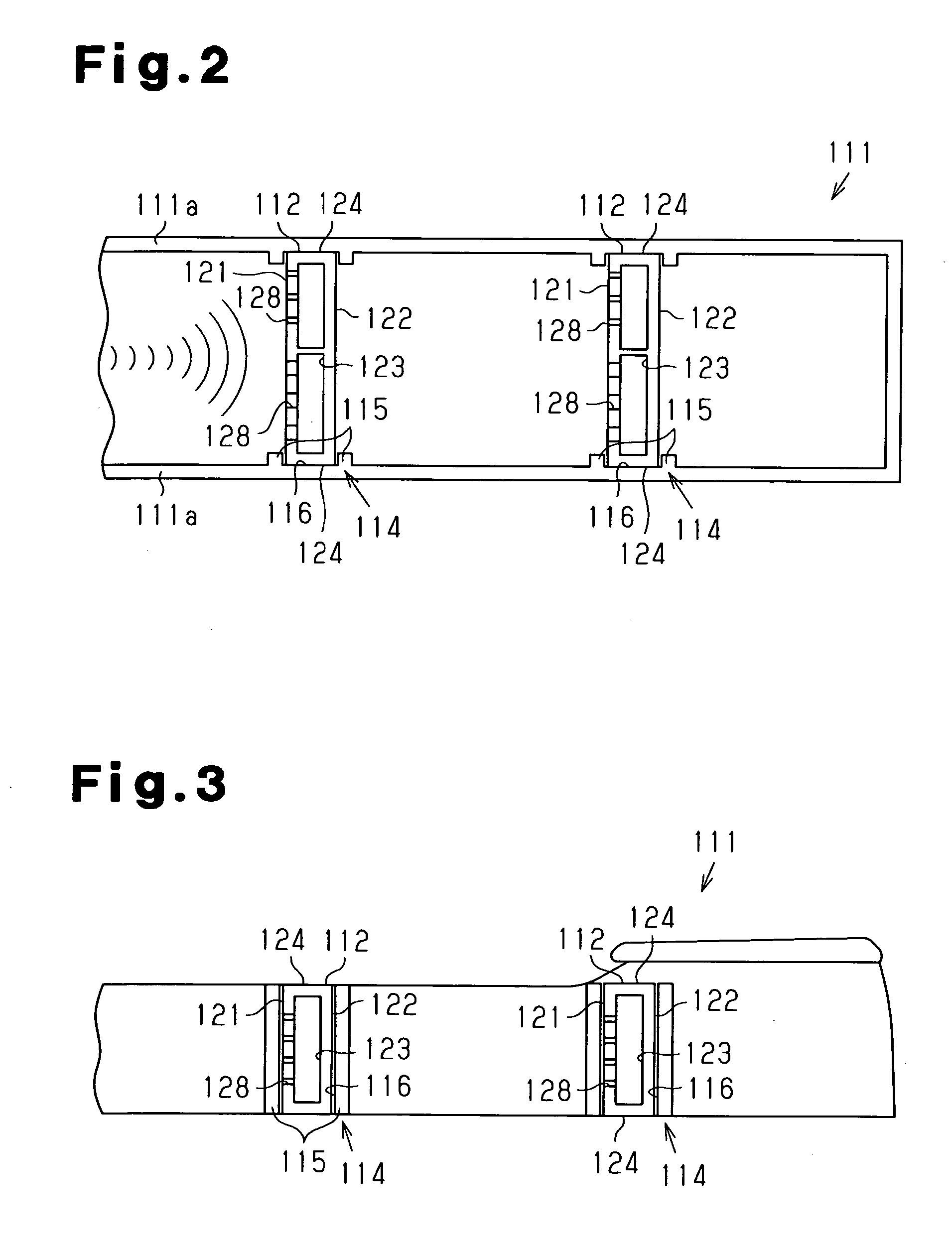

[0039] A first embodiment of a noise absorbing / insulating structure according to the present invention will now be described with reference to FIG. 1 through FIG. 5. The noise absorbing / insulating structure of the first embodiment is installed in a console 111, which is an interior equipment of a vehicle.

[0040] As shown in FIG. 1, the console 111 is arranged between the driver's seat and passenger seat in the passenger compartment. Drive train components (not shown) including the engine and gears are mounted in the front lower part of the vehicle. Various kinds of noise, generated by the drive train components, are propagated through the inner space of the console 111 and leak into the passenger compartment through gaps thereby creating the noise in the passenger compartment. Two noise absorbing / insulating boxes 112 are installed inside the console 111 as noise absorbing bodies for reducing the passenger compartment noise. The two noise absorbing / insulating boxes 112 form a noise a...

second embodiment

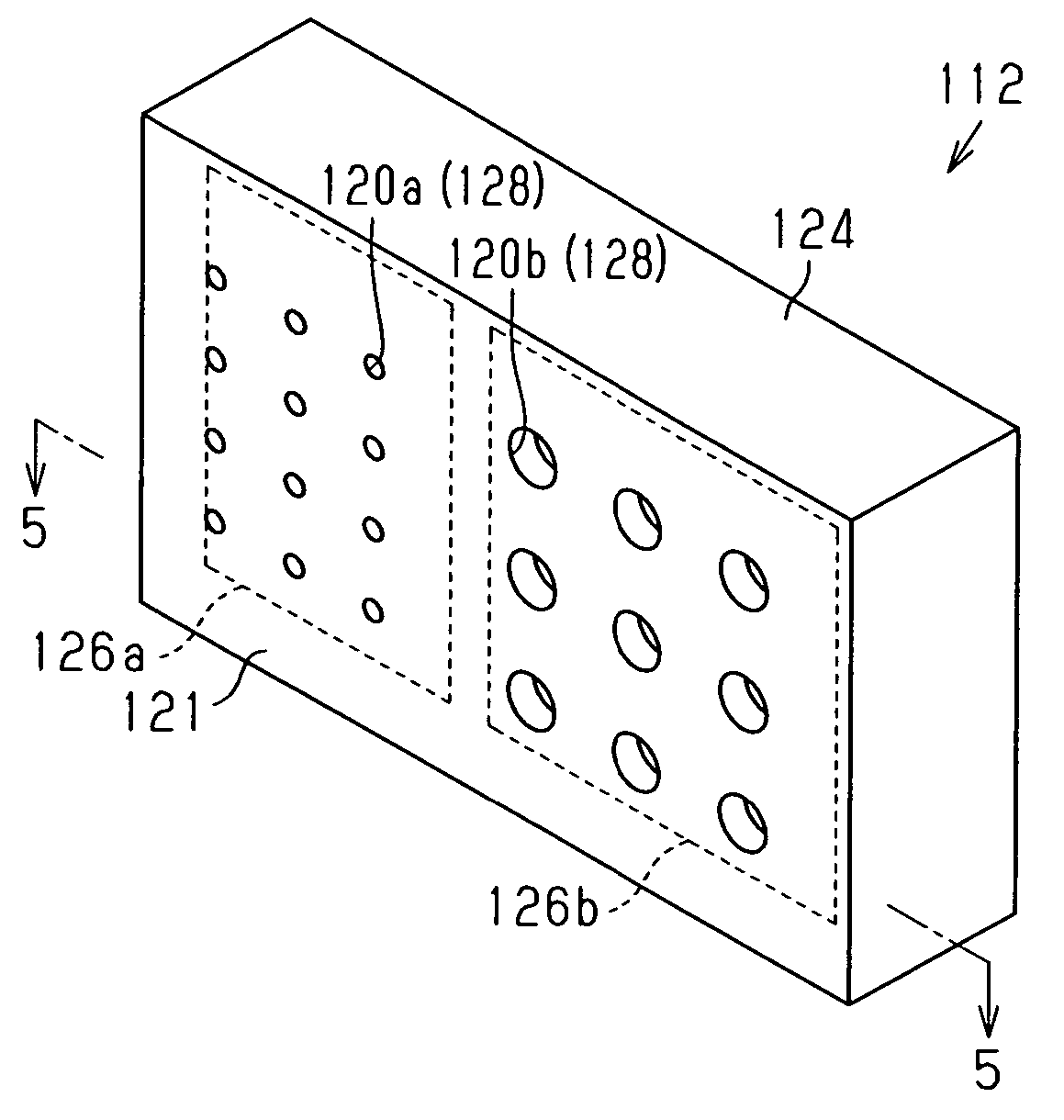

[0060] Hereafter, a noise absorbing / insulating box 132 according to a second embodiment of the present invention will be described with reference to FIGS. 6 and 7. FIG. 6 is a perspective view of the noise absorbing / insulating box 132, and FIG. 7 is a cross-sectional view taken along line 7-7 of FIG. 6.

[0061] As shown in FIG. 6 and FIG. 7, the noise absorbing / insulating box 132 includes first and second noise absorbing / insulating sub-boxes 132a and 132b, which are assembled integrally with each other. The volumes in the first and second noise absorbing / insulating sub-boxes 132a and 132b are the same. The noise absorbing / insulating box 132 is thin and has a rectangular box shape formed by joining the side of the first noise absorbing / insulating sub-box 132a with the side of the second noise absorbing / insulating sub-box 132b.

[0062] In the noise absorbing / insulating box 132 of the second embodiment, the first noise absorbing / insulating sub-box 132a is constructed as a first noise abs...

third embodiment

[0067] A noise absorbing / insulating box 212 according to a third embodiment of the present invention will now be described with reference to FIGS. 8 to 11. In the third embodiment, the noise absorbing / insulating box 212 has a step-like shape as shown in FIG. 10 and is installed in a console 111 as shown in FIGS. 8 and 9.

[0068] As shown in FIGS. 10 and 11, the noise absorbing / insulating box 212 has a first noise absorbing portion 226a, a second noise absorbing portion 226b, and a third noise absorbing portion 226c, which are hollow and are partitioned from each other by first and second partition walls 225a and 225b that link a first wall 221 and a second wall 222. In other words, the noise absorbing / insulating box 212 of the third embodiment is constituted by integrating the first, second, and third noise absorbing portions 226a, 226b, and 226c, each of which has a rectangular box shape. The first wall 221 is formed to have a step-like shape as a whole. The first and second partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com