Apparatus and method for cleaning membrane filtration modules

a technology of filtration module and apparatus, which is applied in the direction of filtration separation, membranes, separation processes, etc., can solve the problems of large energy consumption, inability to achieve continuous filtering, so as to improve the quality of filtrate and reduce the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

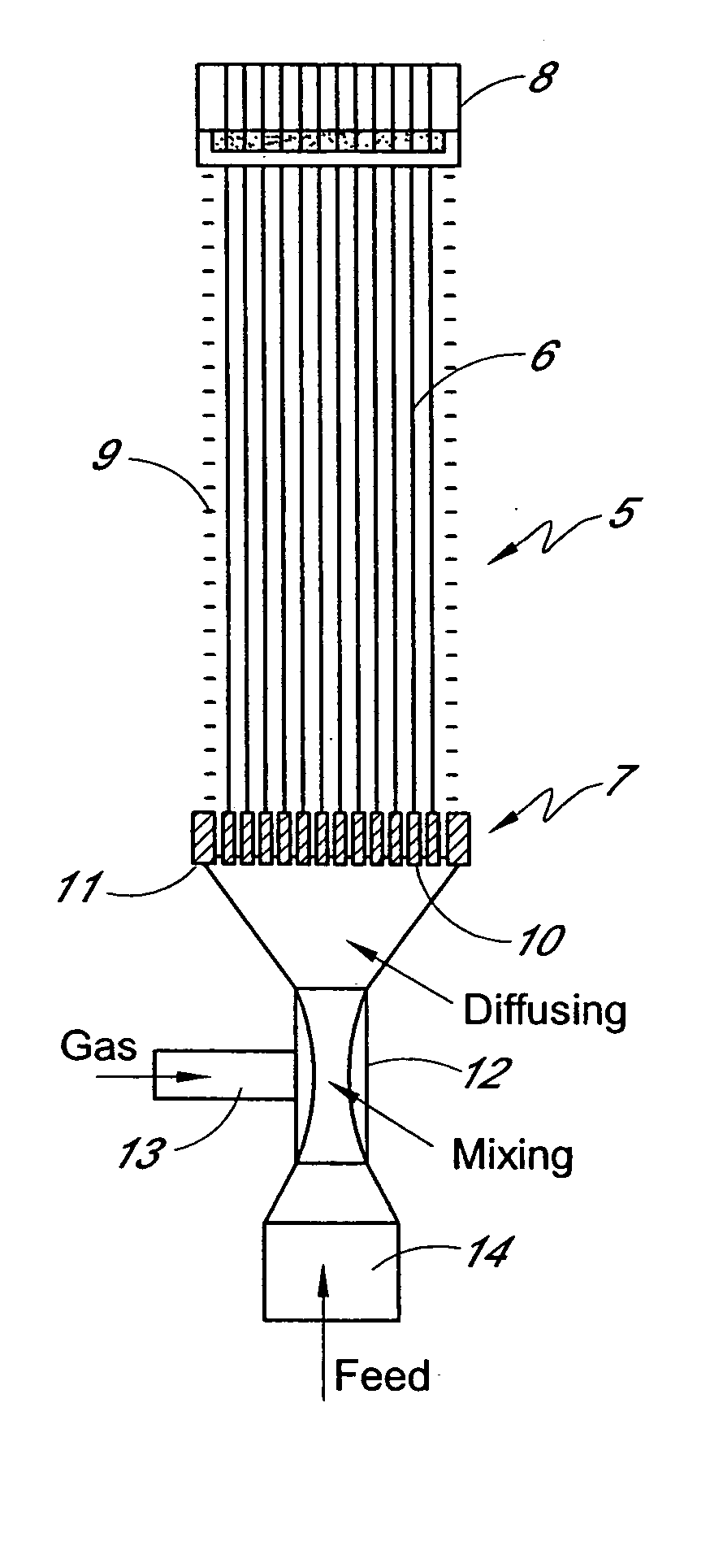

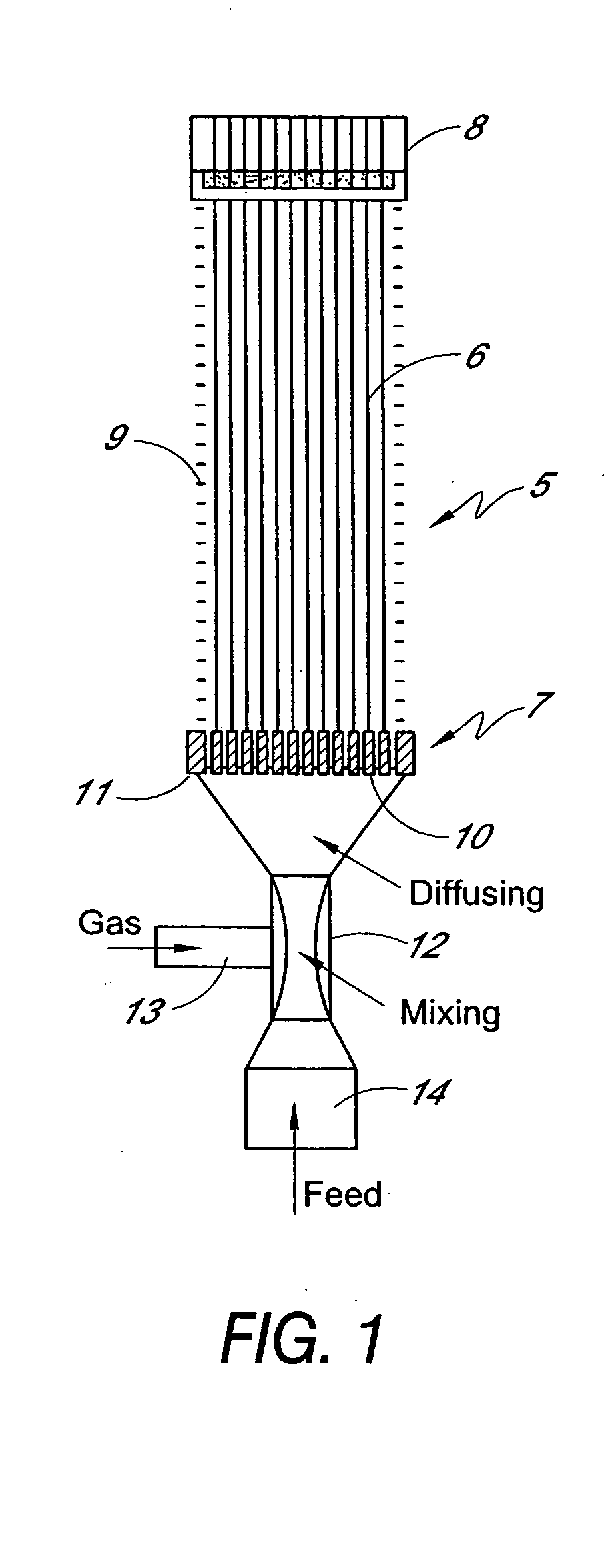

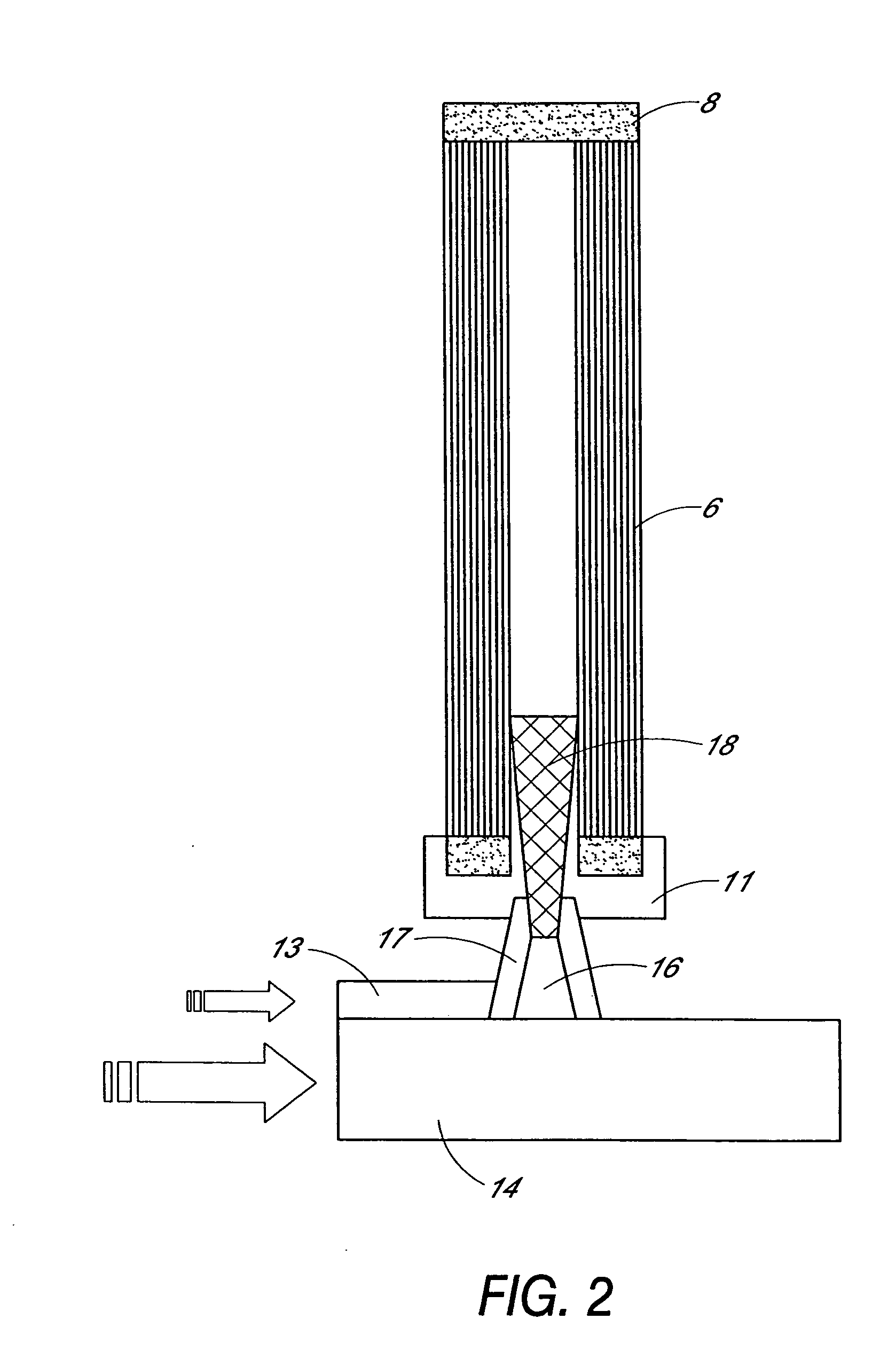

[0041] Referring to the drawings, the embodiments of the invention will be described in relation to a membrane module of the type disclosed in our earlier PCT application No. WO98 / 28066 which is incorporated herein by cross-reference, however, it will be appreciated that the invention is equally applicable to other forms of membrane module. The membrane module 5 typically comprises fibre, tubular or flat sheet form membranes 6 potted at two ends 7 and 8 and encased in a support structure, in this case a screen 9. Either one or both ends of the membranes may be used for the permeate collection. The bottom of the membrane module has a number of through apertures 10 in the pot 11 to distribute a mixture of gas and liquid feed past the membrane surfaces.

[0042] Referring to the embodiment shown in FIG. 1, a venturi device 12 or the like is connected to the base of the module. The venturi device 12 intakes gas through inlet 13, mixes or entrains the gas with liquid flowing through feed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com