Fluid compressor

a compressor and fluid technology, applied in the field of fluid compressors, can solve the problems of lowering fuel efficiency of hydrogen gas, high humidity of hydrogen off gas, and interference with normal activation of fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

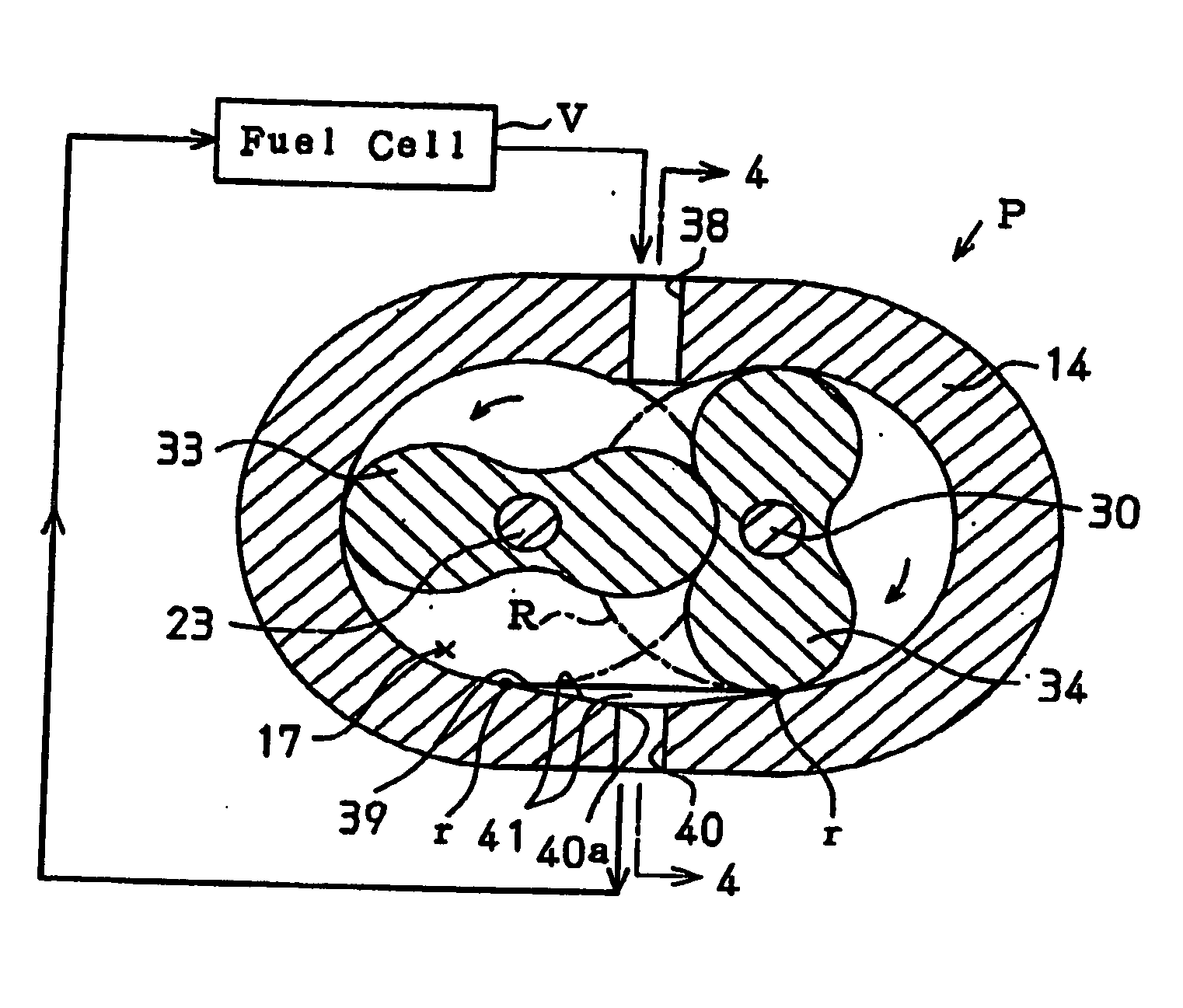

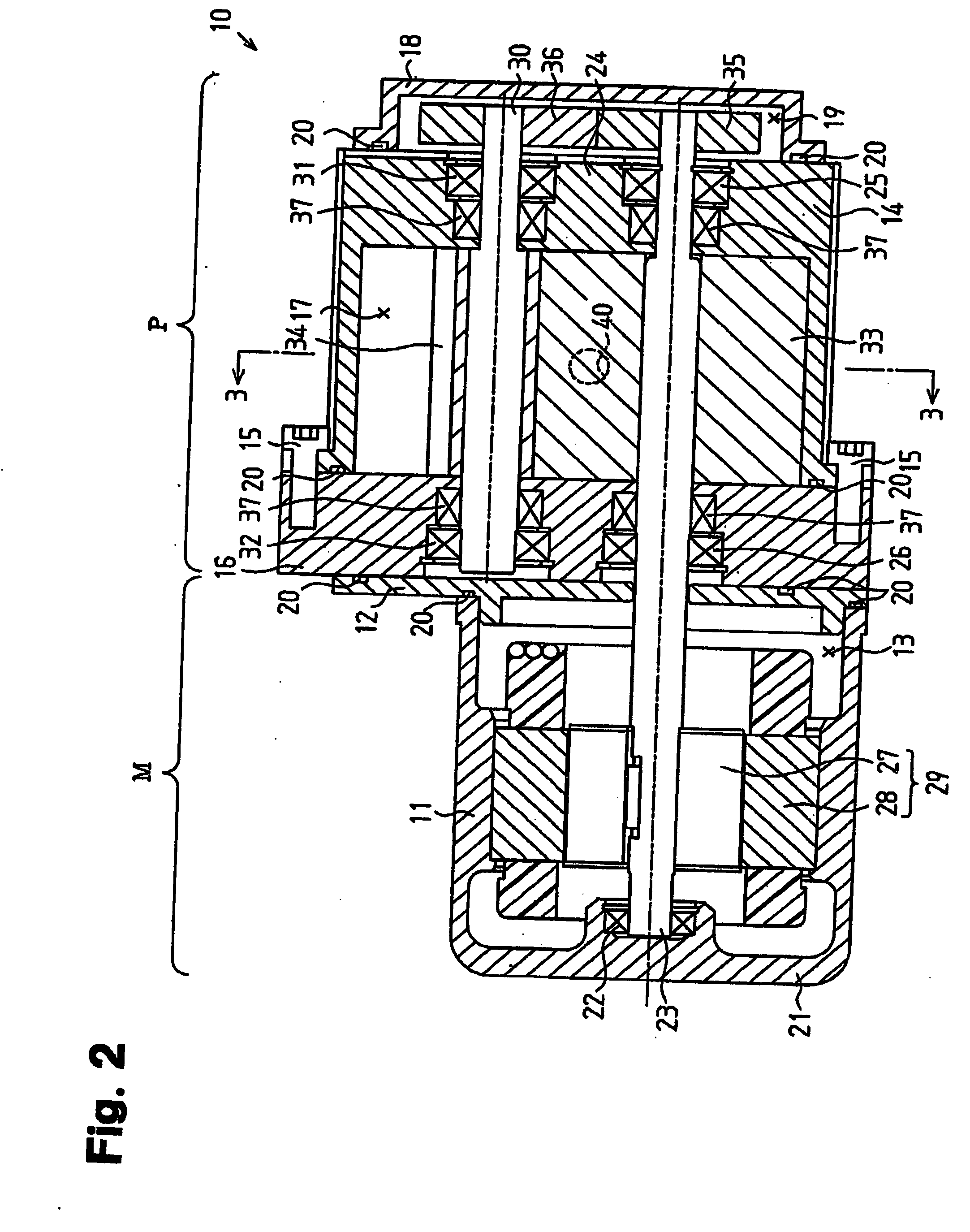

[0017] A hydrogen compressor 10 according to a preferred embodiment of the present invention will now be described with reference to FIGS. 2 to 4. The hydrogen compressor 10 is one type of fluid compressor that is used in a fuel cell system.

[0018] Referring to FIG. 2, in the preferred embodiment, the hydrogen compressor 10 includes a motor M and a root pump P. The motor M includes a motor housing 11, which is cylindrical, and a partition wall 12. The motor housing 11 has a closed first end (left end as viewed in FIG. 2) and an open second end (right end as viewed in FIG. 2). The partition wall 12 is coupled to the motor housing 11 so as to close the open second end of the motor housing 11. A motor chamber 13 is defined by the inner surface of the motor housing 11 and the inner surface of the partition wall 12. The pump P includes a pump housing 14, which has the shape of a generally oval cylinder with a closed end, and a bearing block 16. The pump housing 14 has an open first end (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com