Break-away gas check for muzzle-loading firearms

a technology of firearms and gas check, which is applied in the direction of weapons, missile propulsion, ammunition projectiles, etc., can solve the problems of significant reduction in the efficiency of such firearms, malformed when being placed, and destructive interactions between bullets and bores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

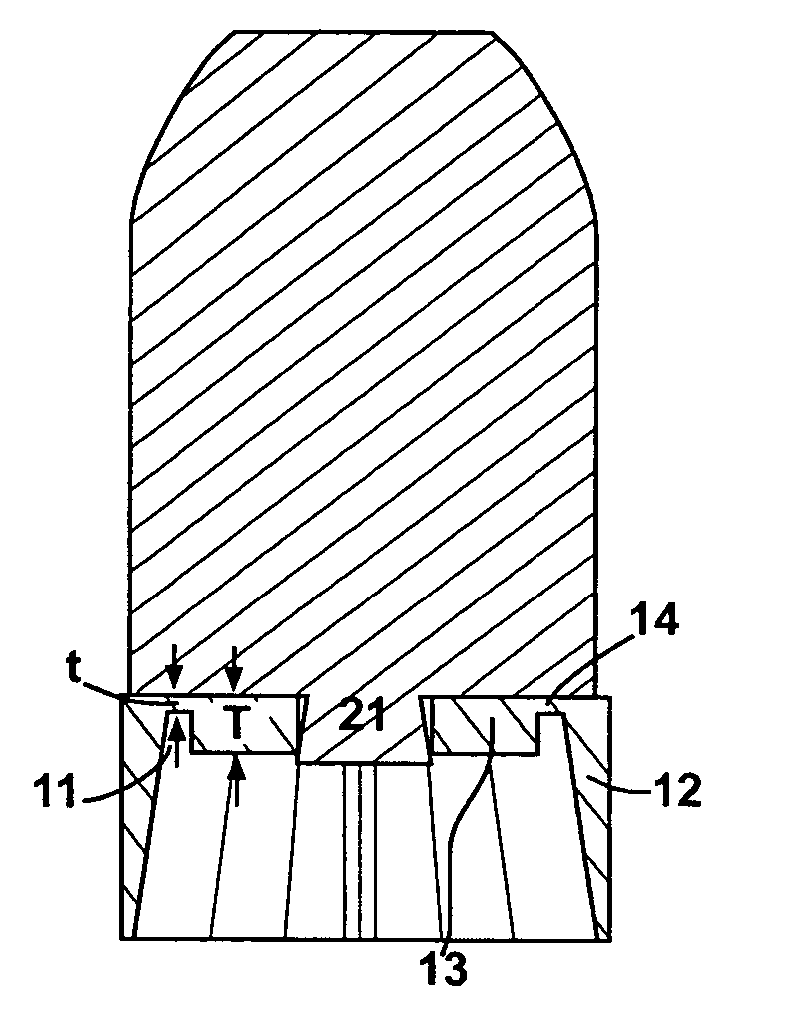

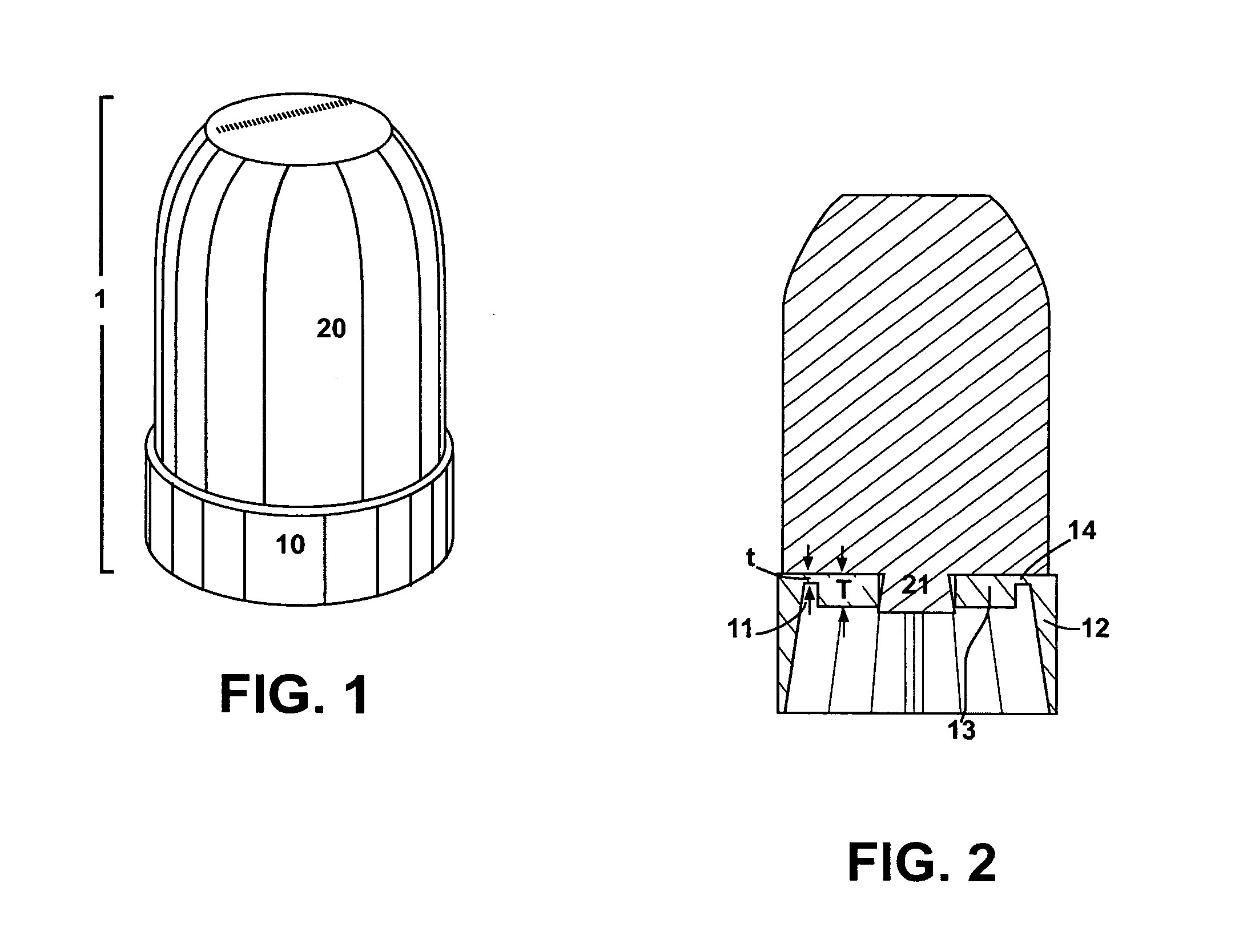

[0024] Referring to the Figures, there are shown several, but not the only, embodiments of the invented gas check member. The gas check is designed for use in combination with a bullet, and therefore is drawn in combination with a bullet in FIGS. 1, 2, 4, 5, and 7. The combination of a gas check member with a bullet will herein be referred to as a projectile.

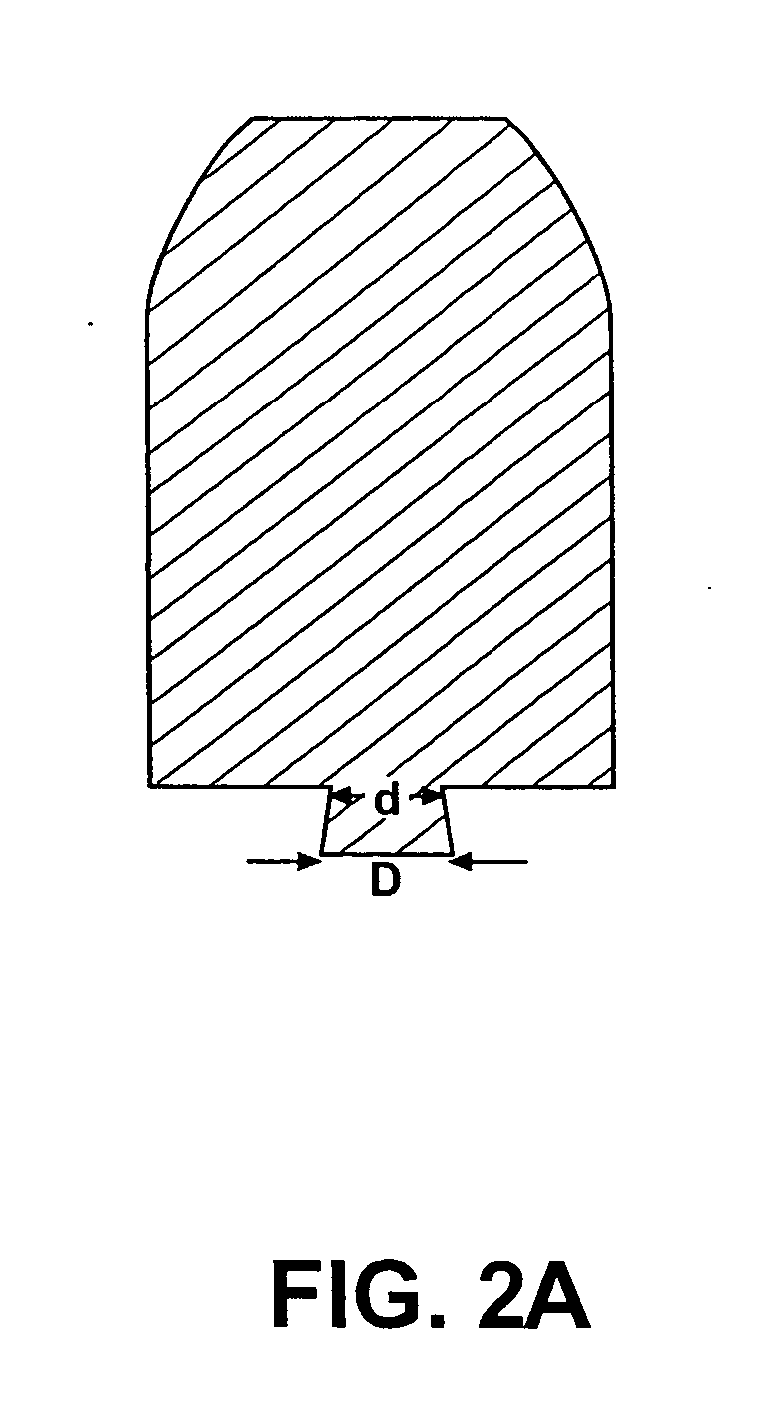

[0025] In FIGS. 1-5, gas check member 10 comprises a generally cylindrical element preferably constructed of a resilient plastic material and engineered to attach rearward of the maximum diameter of the bullet 20, as shown in FIGS. 1 and 2. The maximum diameter of the bullet is preferably slightly less than that of the bore, and the diameter of the gas check member exceeds that of both bullet and bore 50. This relationship is illustrated in FIG. 4. Bullets used in muzzle-loading firearms are typically composed of a suitable solid, but deformable, material such as lead, and exhibit a tapered cylindrical, ogive or blunted ogive d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com