Central toilet/bathroom venting

a toilet and central technology, applied in the direction of lavatory sanitory, water installation, construction, etc., can solve the problem that odors cannot be allowed to fill the room, and achieve the effect of facilitating the attachment of energy recovery systems, facilitating indoor air quality improvement and circulation, and promoting energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

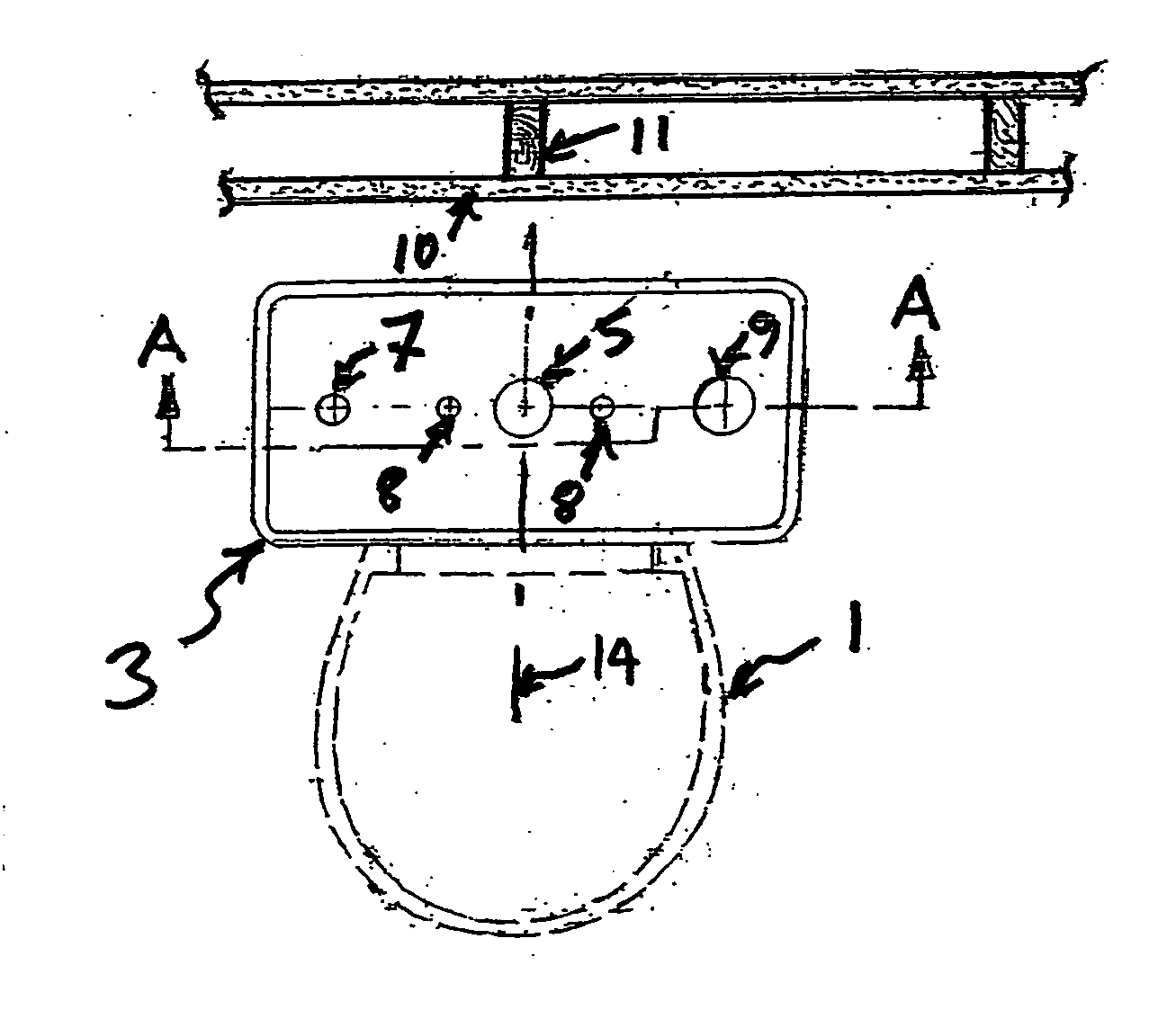

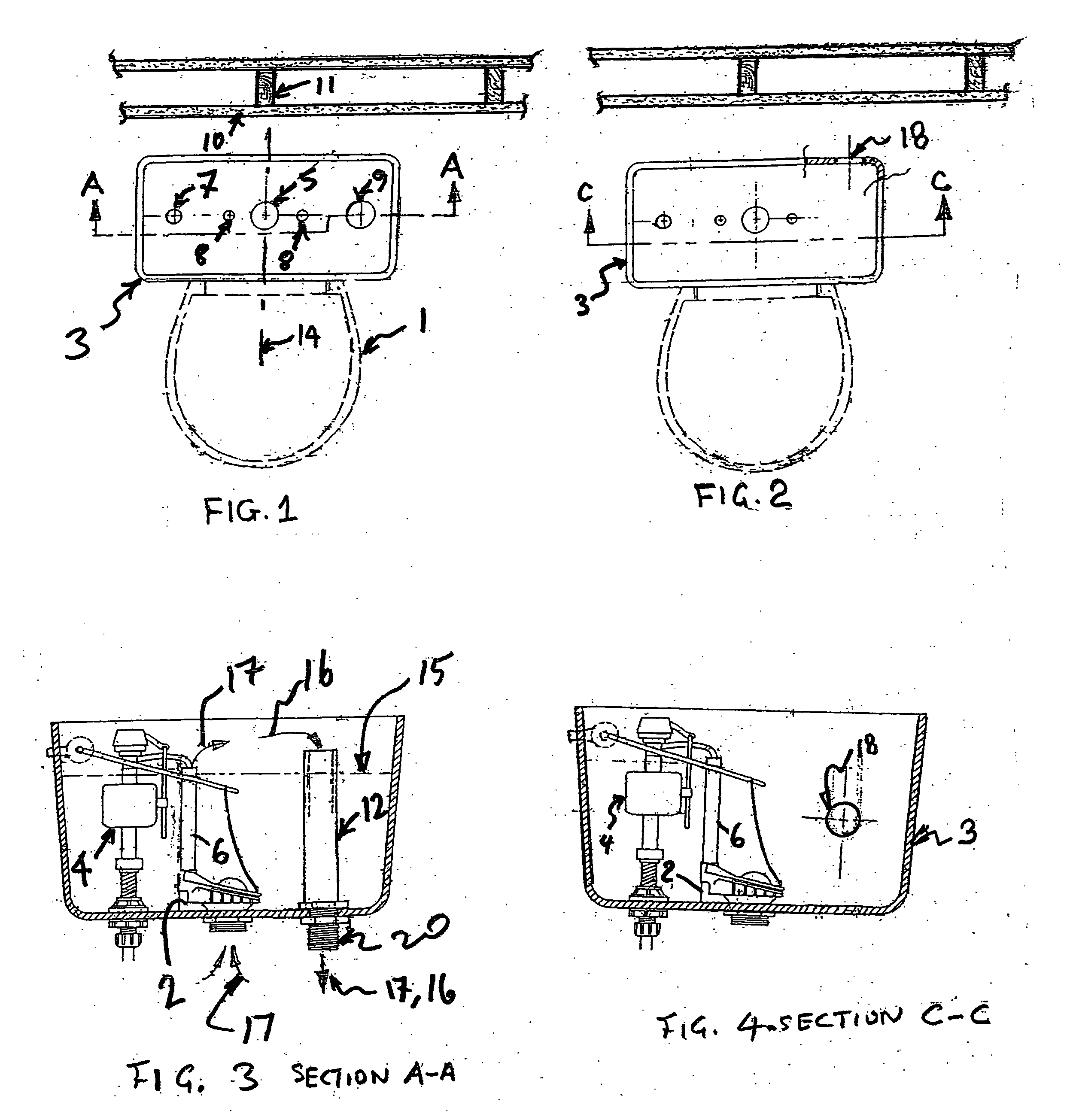

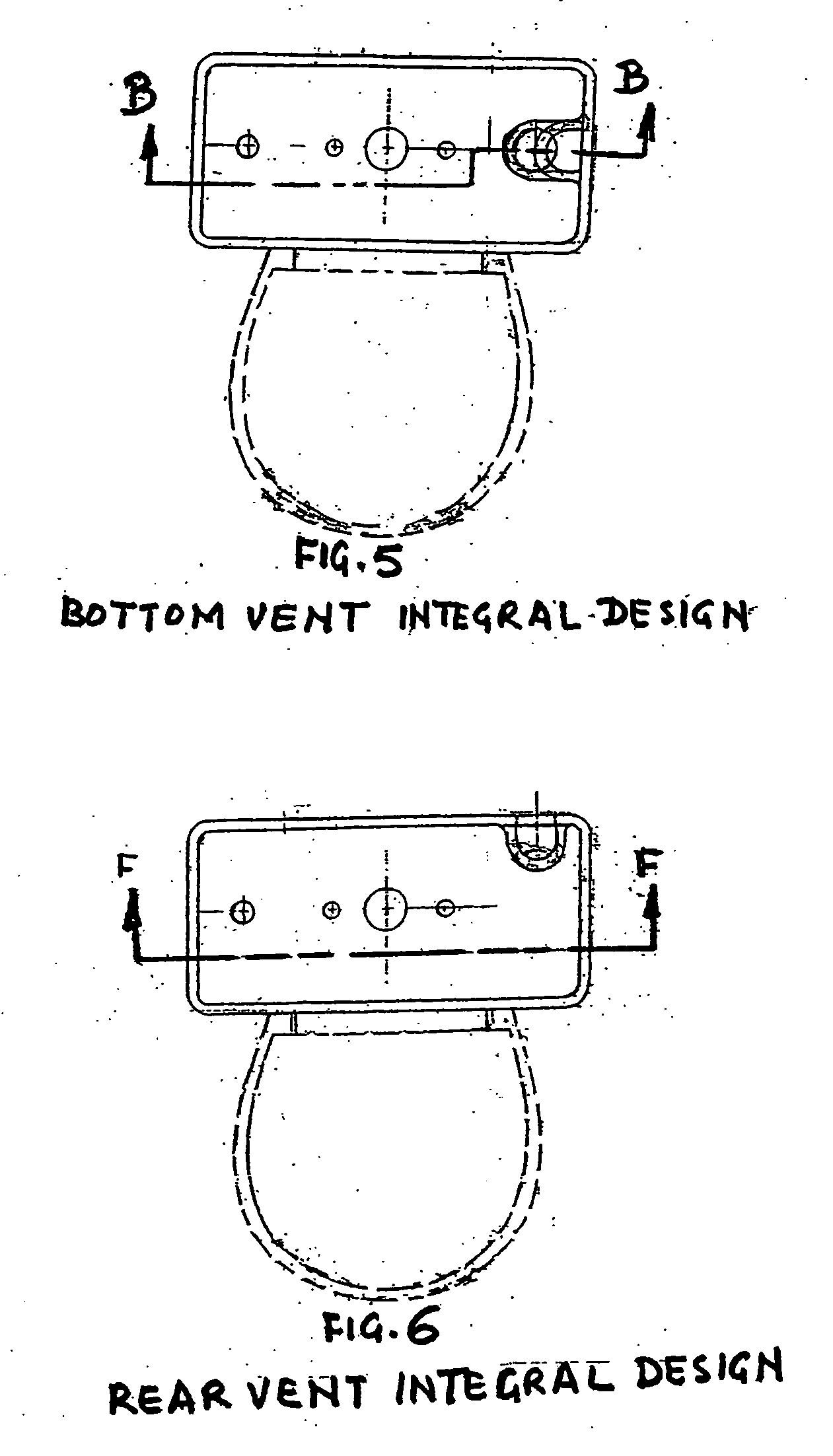

[0029] In accordance with a first embodiment of the present invention, there is provided a venting system as depicted in FIG. 11. The venting system includes toilet assemblies having special features in terms of a venting opening at the bottom of the tank, FIG. 11A and / or a venting opening at the back of the tank as in, FIG. 11B. The venting system also includes branch conduits 23 which are connected to a larger central venting conduit 24. The larger conduit 24 is connected to an electrically driven or powered fan / blower or energy recovery exhaust system 25. The venting system and assembly has a final discharge outlet 26 which is equipped with a back draft prevention damper 27. The purpose of the back draft damper is to prevent reverse flow of what the fan is exhausting through the ducts and conduits when the fan is off.

[0030]FIG. 11 shows one of the most efficient modes for utilizing this invention by connecting appropriate exhaust lines to outlet connectors 20 so that the odors w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap