Support bracket to suspend sheet material for a wall

a technology of supporting brackets and wall supports, which is applied in the field of brackets, can solve the problems of not being ideally suited, cumbersome to use, and relatively complex known devices, and achieve the effects of convenient nailing or screwing of sheets, low manufacturing cost, and low cost of brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

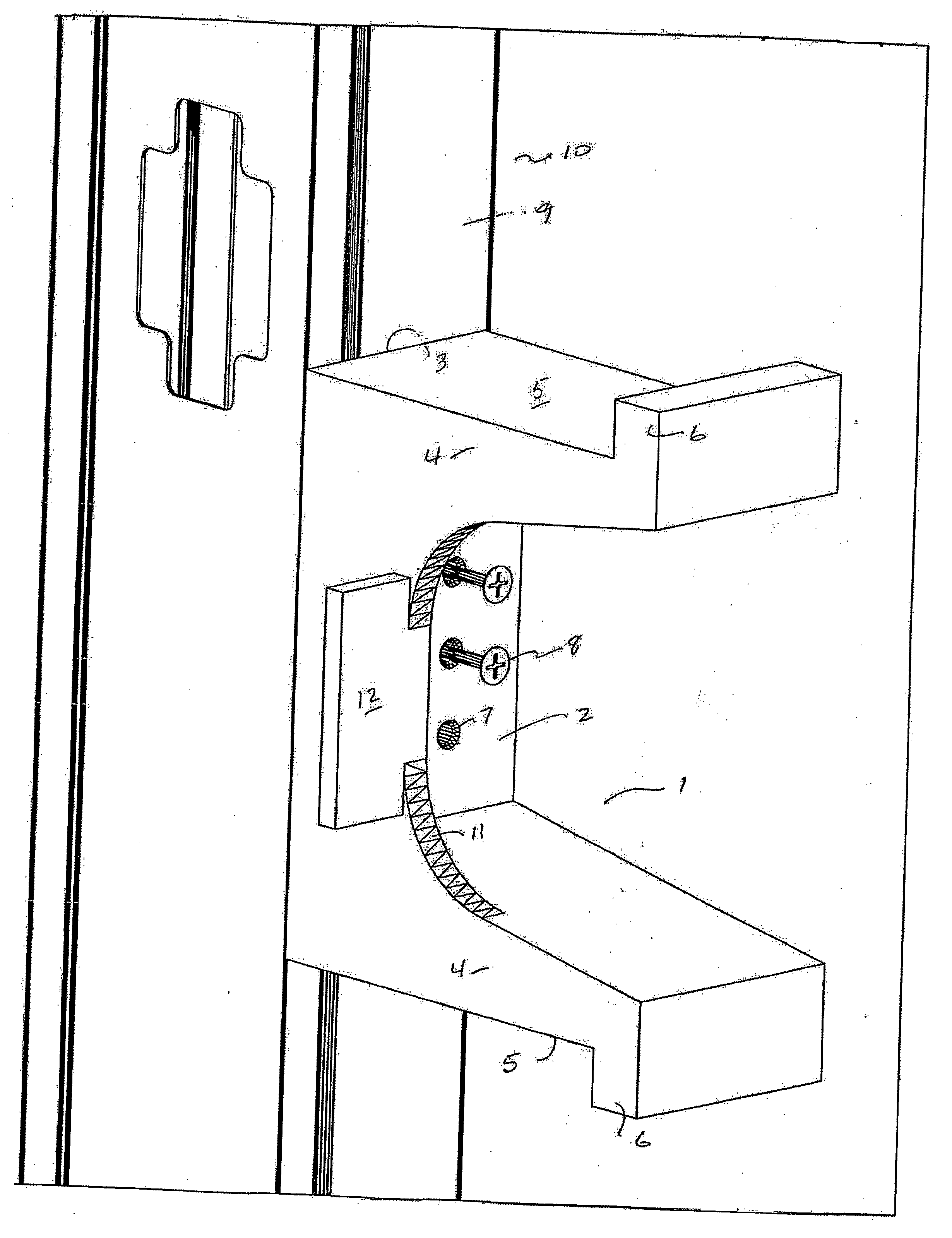

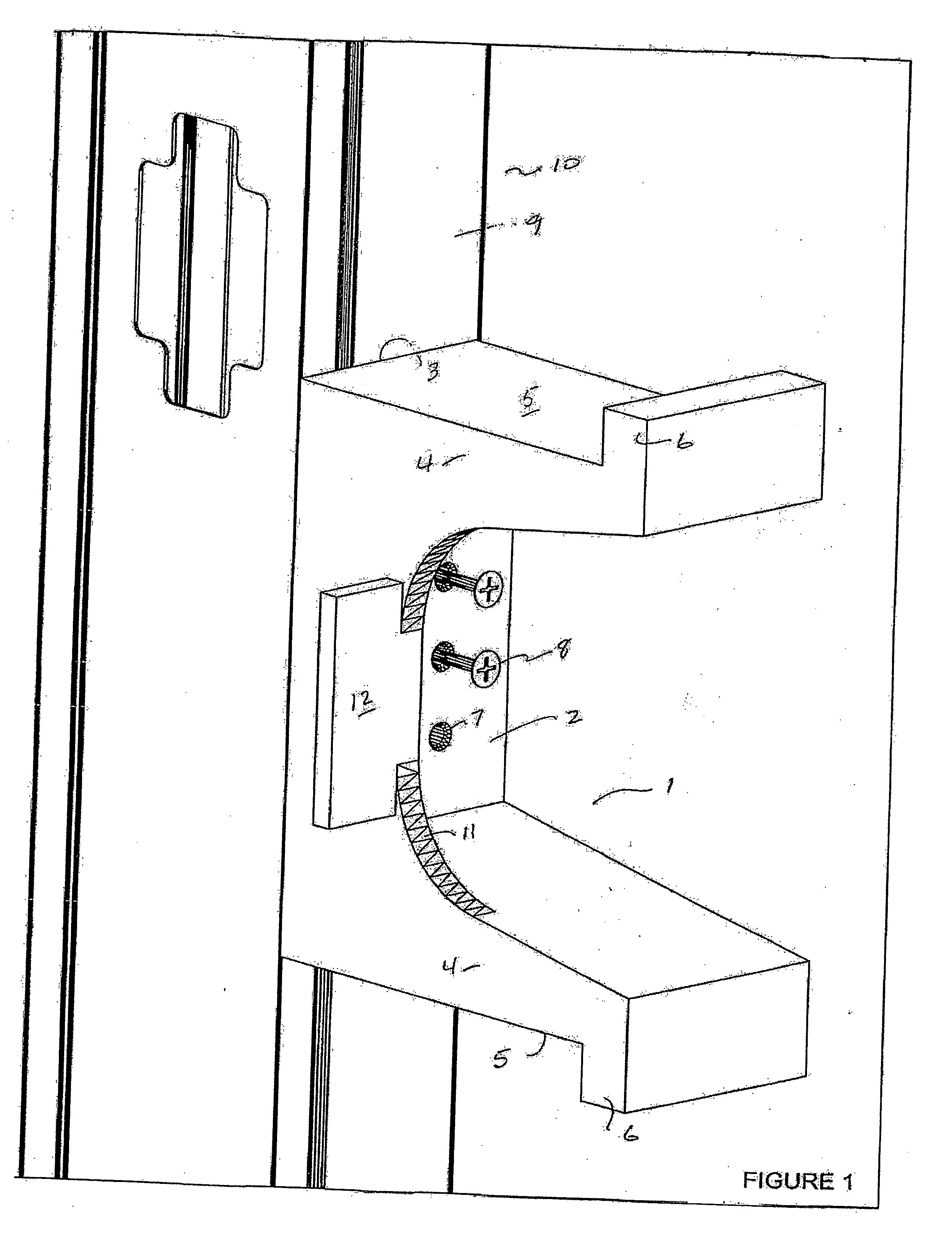

[0023] Referring now to FIG. 1, the bracket 1 comprises a flat rectangular base 2 having a bottom stud contact surface 3.

[0024] A pair of vertically spaced apart, horizontal, oppositely directed, L-shaped support arms 4 project forwardly from the base 2. The support arms 4 each provide a panel-supporting surface 5 and a panel-retaining lip 6.

[0025] Through holes 7 are formed in the base 2, through which threaded fasteners 8 may be driven to fasten the bracket 1 onto the side surface 9 of the stud 10.

[0026] A first flange 11 protrudes forwardly from the base 2 and joins the support arms 4 at their lower ends at one side. The flange 11 functions to reinforce the support arms 4. A second flange 12 projects sideways from the first flange 11, to provide means for the installer to grasp to firmly hold the bracket 1.

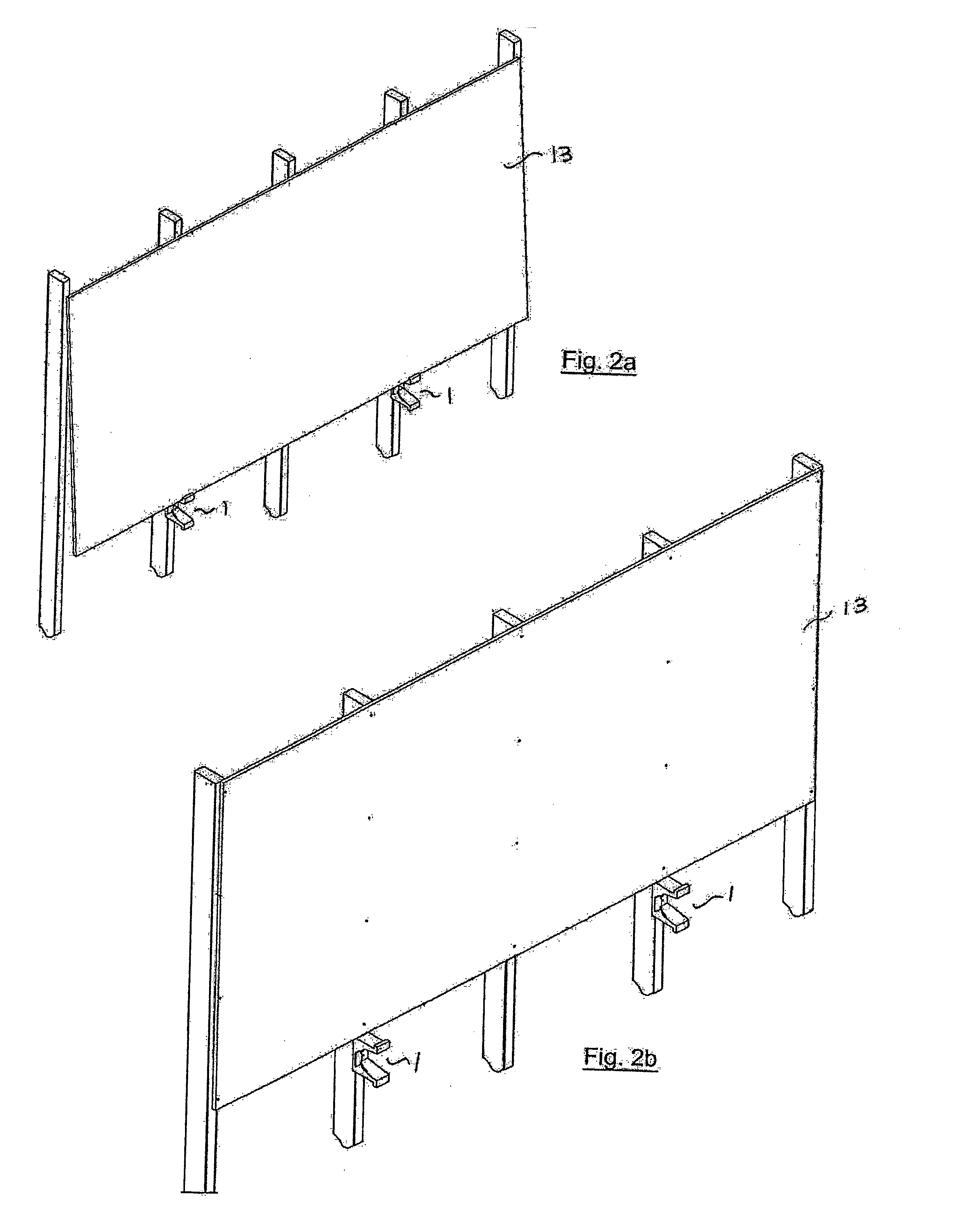

[0027] The support arms 4 of the brackets 1 provide temporary support for a section or panel of dry wall 13 at an elevated position on the wall frame prior to final positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com