Filtered wringer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

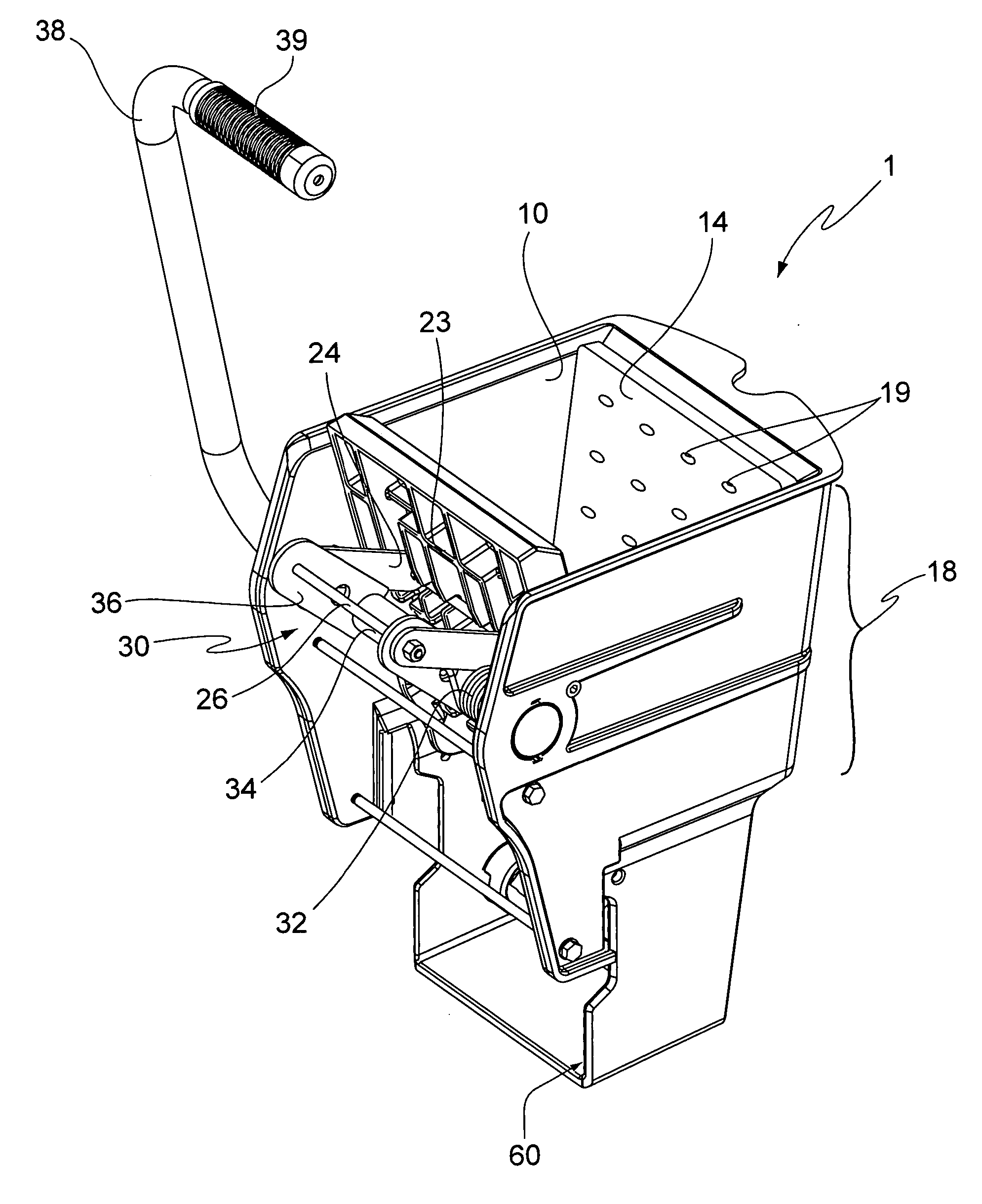

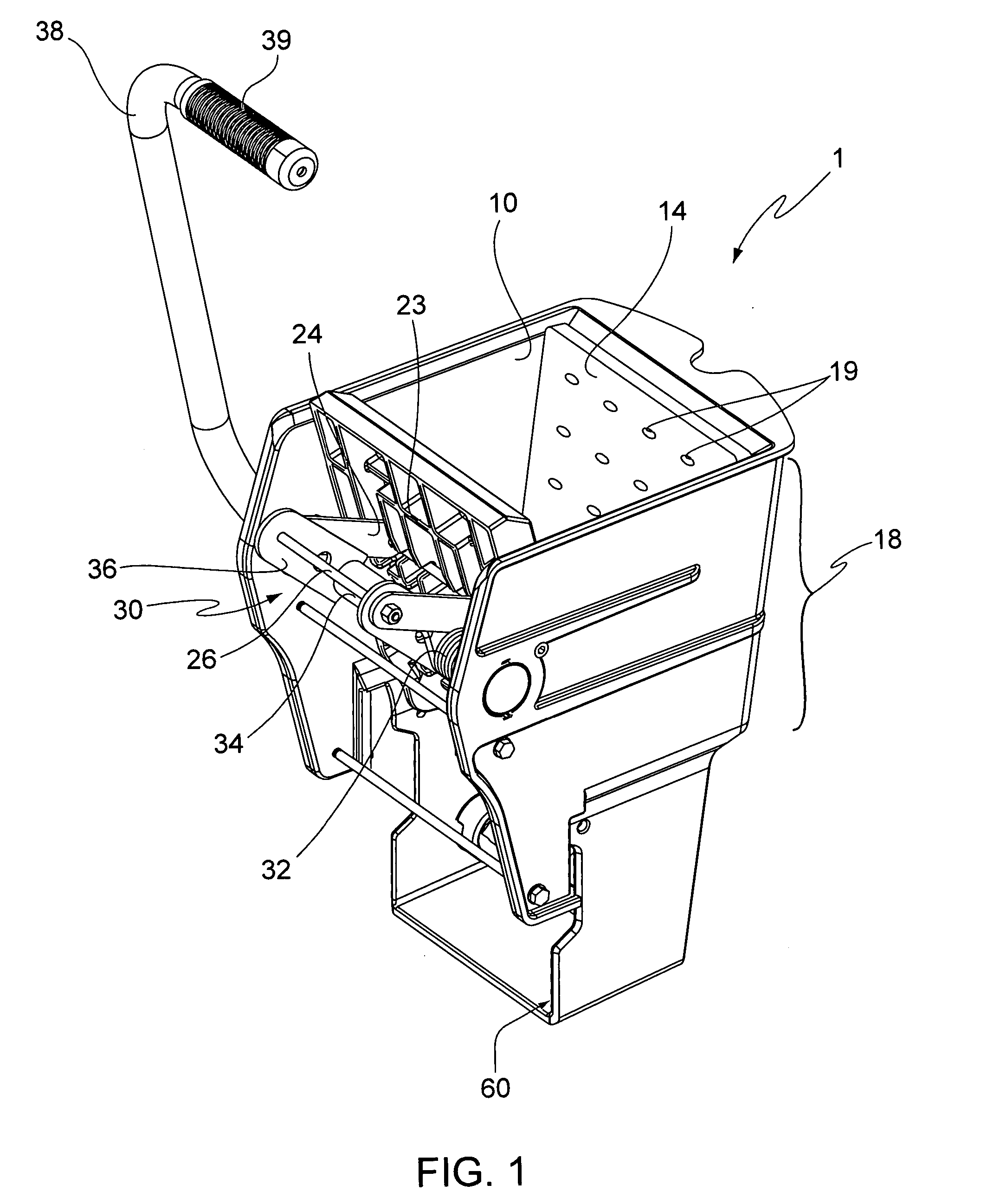

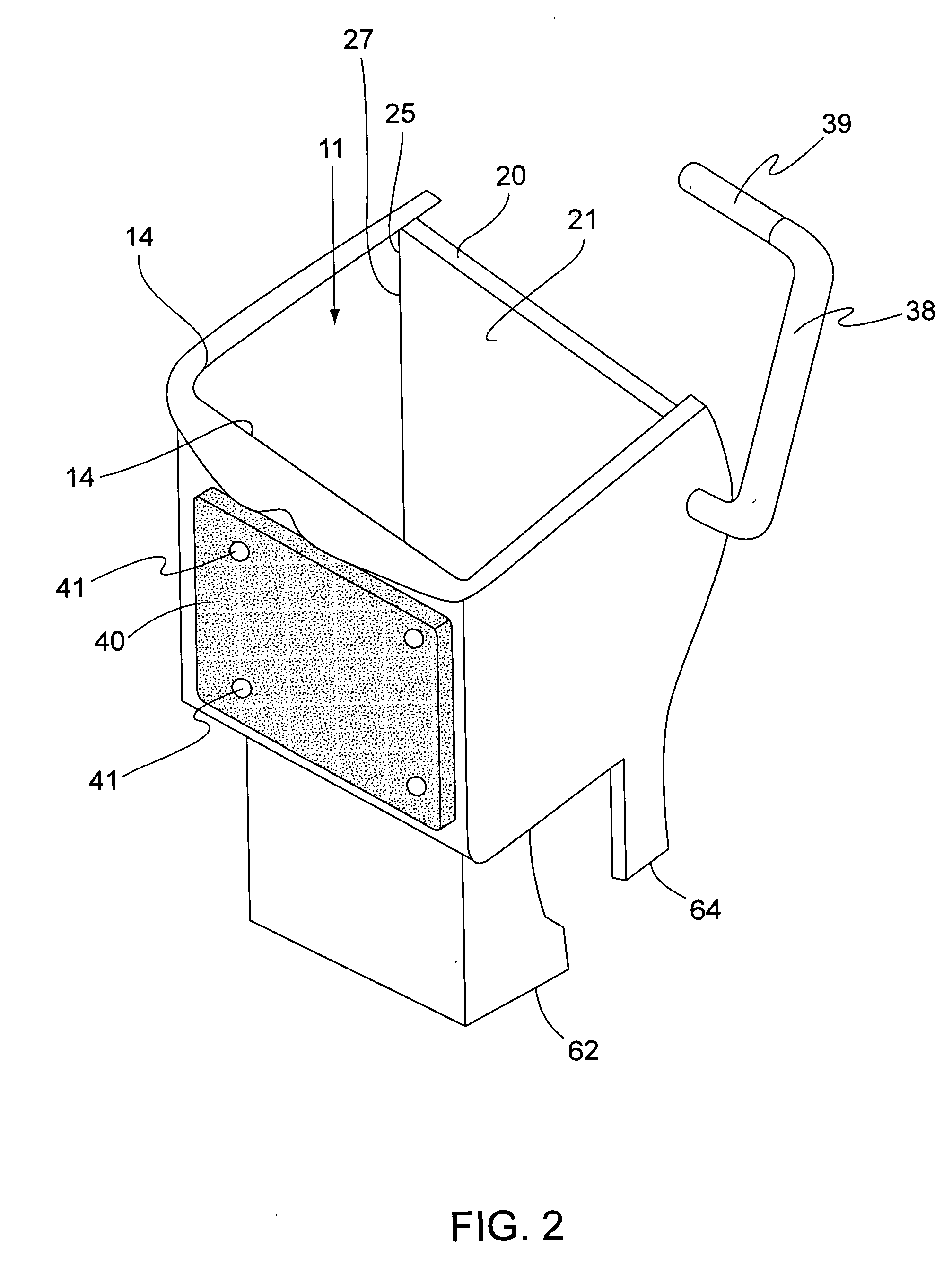

[0024]FIGS. 1-4 illustrate a first preferred embodiment of the present invention as described herewith. Wringer 1 generally comprises container 10, actuator 30, filter 40, and attachment member 60. Container 10 has open top 12, a plurality of side walls 14, movable section 20, and perforated section 18, which define an internal volume 11. Movable section 20 is movable from a first position A to a second position B (see FIGS. 3A and 3B, further described below), which reduces the size of internal volume 11. Sealing members 24 on edges 22 of movable section 20 minimize the leakage of fluid from container 10 where movable section 20 meets side walls 14. However, even if some fluid is able to leak out of container 10 through edges 22, this does not seriously hamper the effectiveness of the present invention. In a preferred embodiment, the components of container 10 are made of plastic, although other materials, such as metal, may also be used.

[0025] Movable section 20 is generally rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com