Drawer for a heated food cabinet

a technology for food cabinets and drawers, which is applied in the field of drawers for heated food cabinets, can solve the problems of affecting the service life of the food cabinet, and increasing the effort and time required to clean and sanitize the food storage area, so as to facilitate full access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

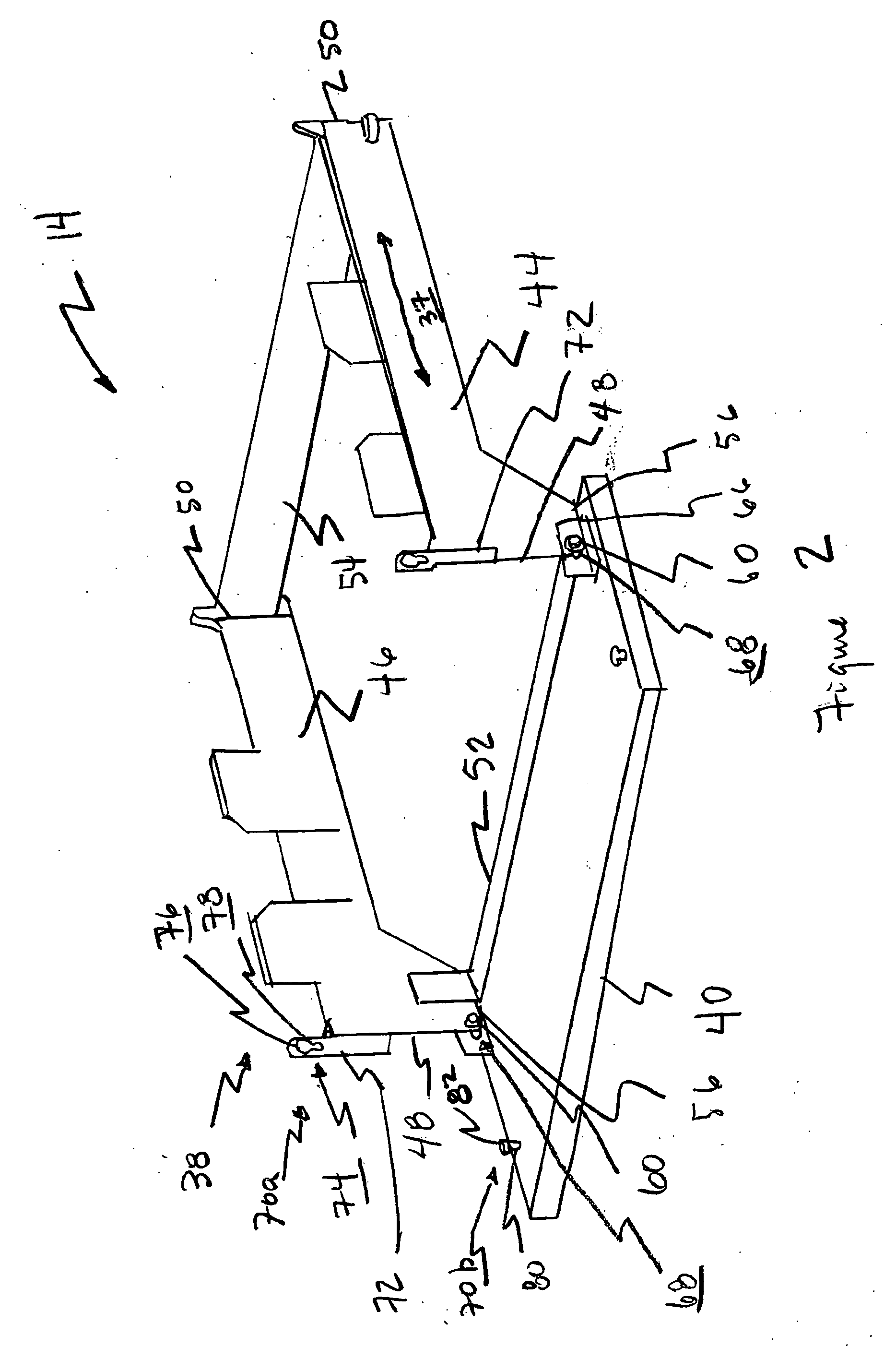

[0018] Refer now to the drawings wherein depicted elements are not necessarily shown to scale and wherein like or similar elements are designated by the same reference numeral through the several views.

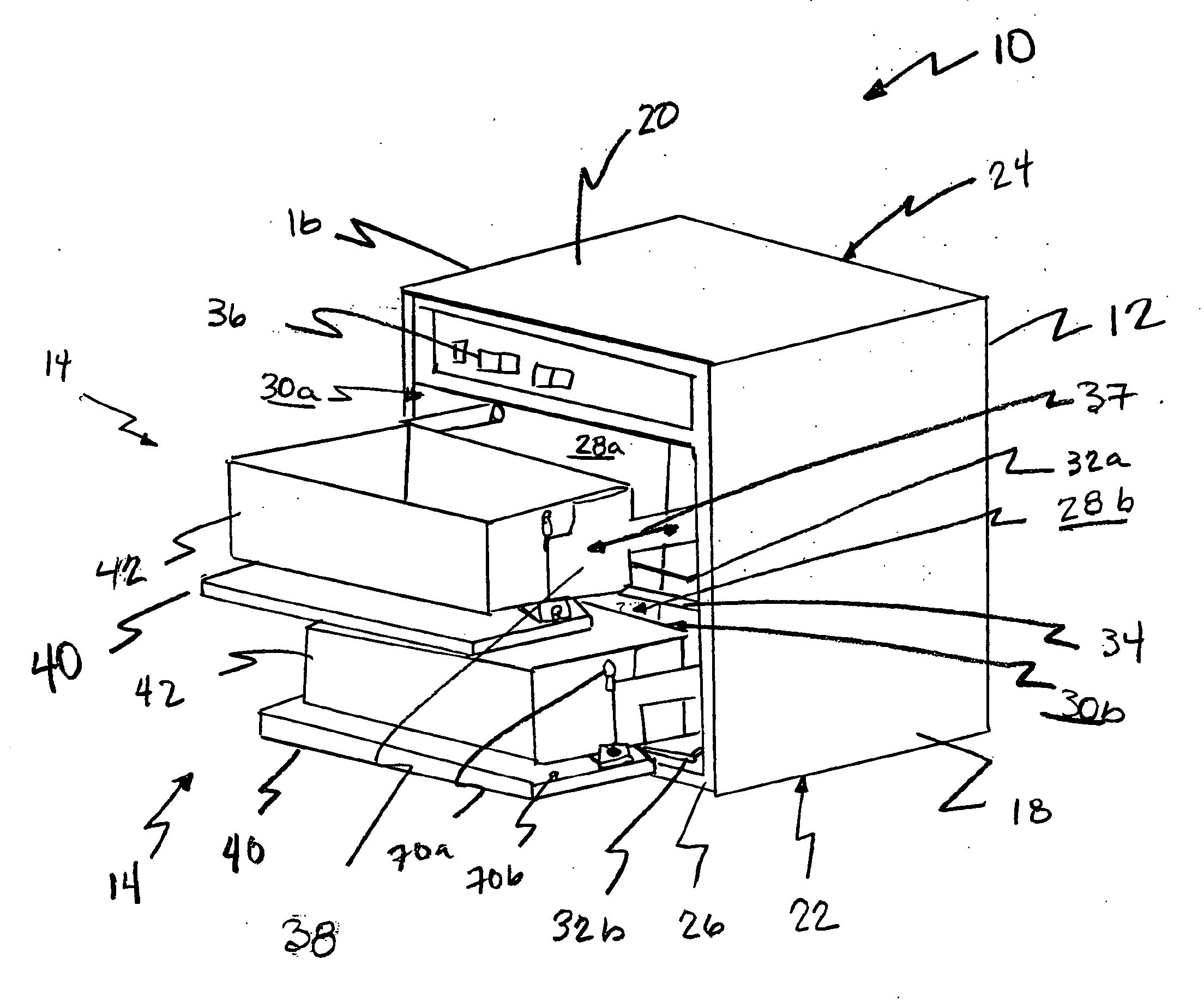

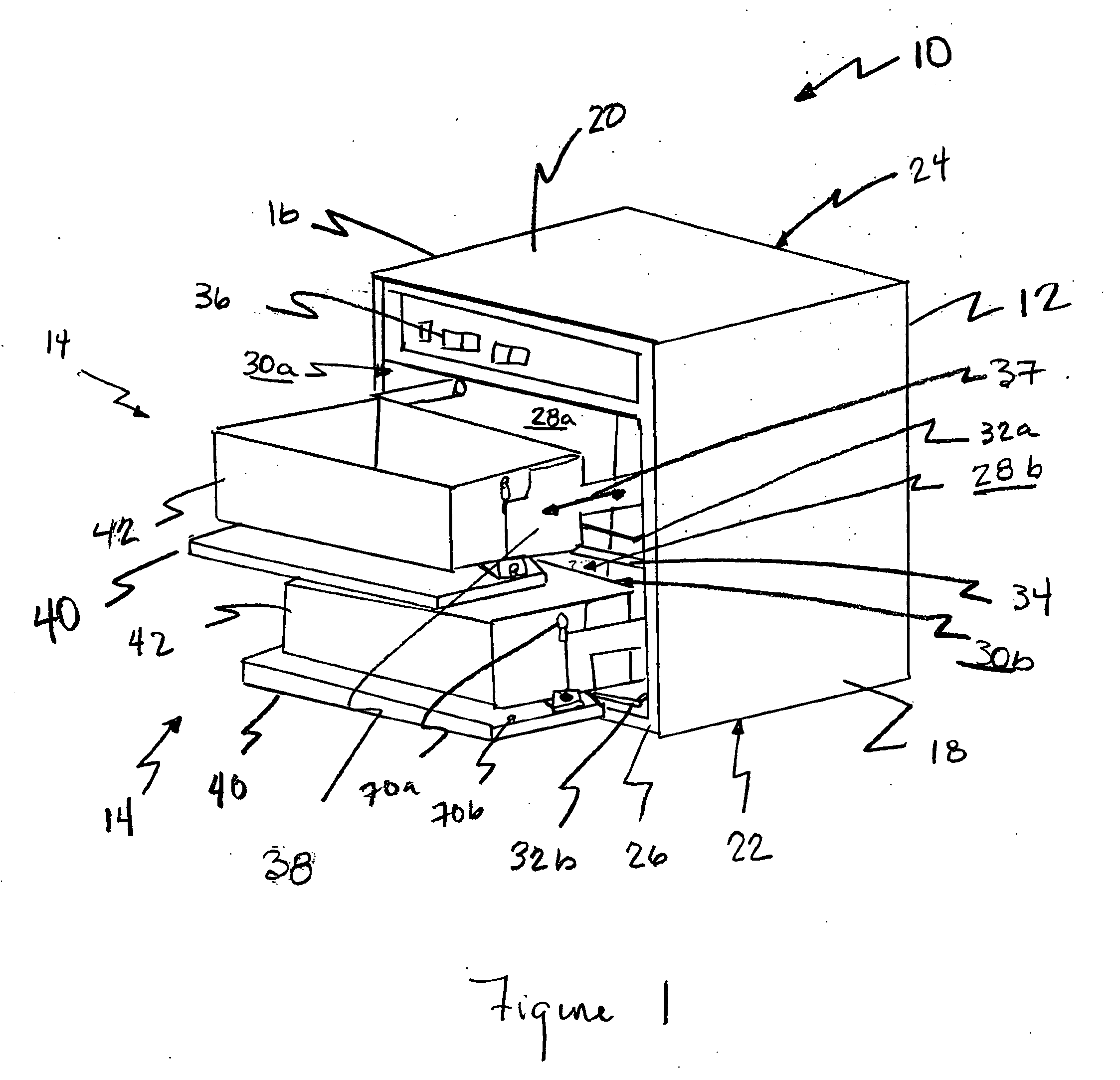

[0019]FIG. 1 is a perspective view of a positional drawer door for a food cabinet of the present invention generally designated by the numeral 10. The present invention includes a food cabinet 12 and a drawer, generally designated by the numeral 14, that is movable between a closed position in which drawer 14 is positioned within food cabinet 12 and an opened position wherein drawer 14 extends from cabinet 12.

[0020] Cabinet 12 may be a cooking or warming oven or holding oven. Cabinet 12 includes opposing side walls 16, 18, a top wall 20, a bottom wall 22, a back wall 24, and a front wall 26 forming a heated cavity 28. Cabinet 12 may be constructed of stainless steel, aluminum or other suitable material for a heating apparatus.

[0021] Access to heated cavity 28 is formed by openings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com