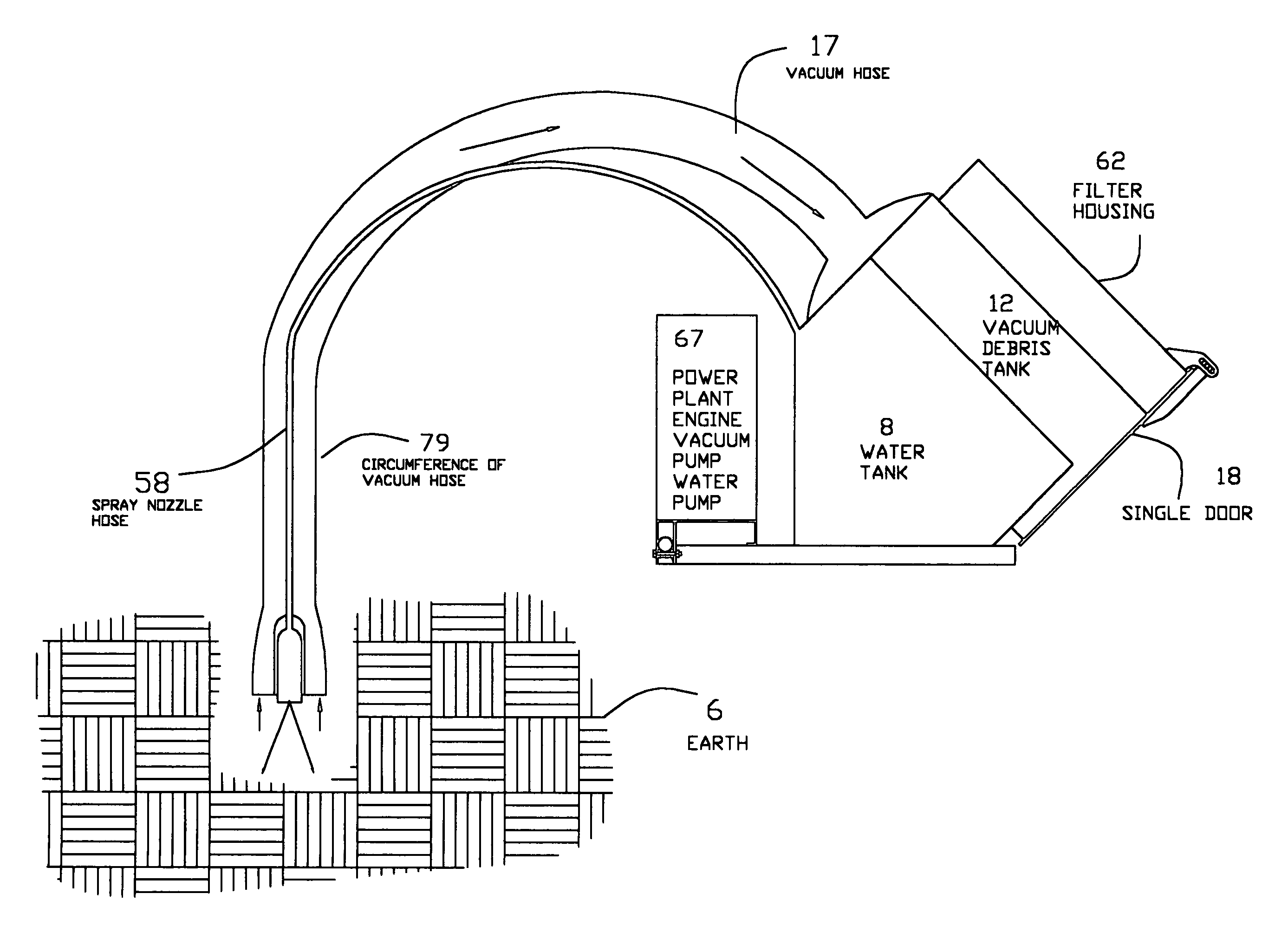

Vacuum excavation suction hose attachment

a vacuum hose and suction hose technology, applied in the field of hose attachments, can solve the problems of limiting the maximum size of debris entering the vacuum hose, affecting the velocity of air and debris travel, etc., and achieve the effect of reducing the size of the opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

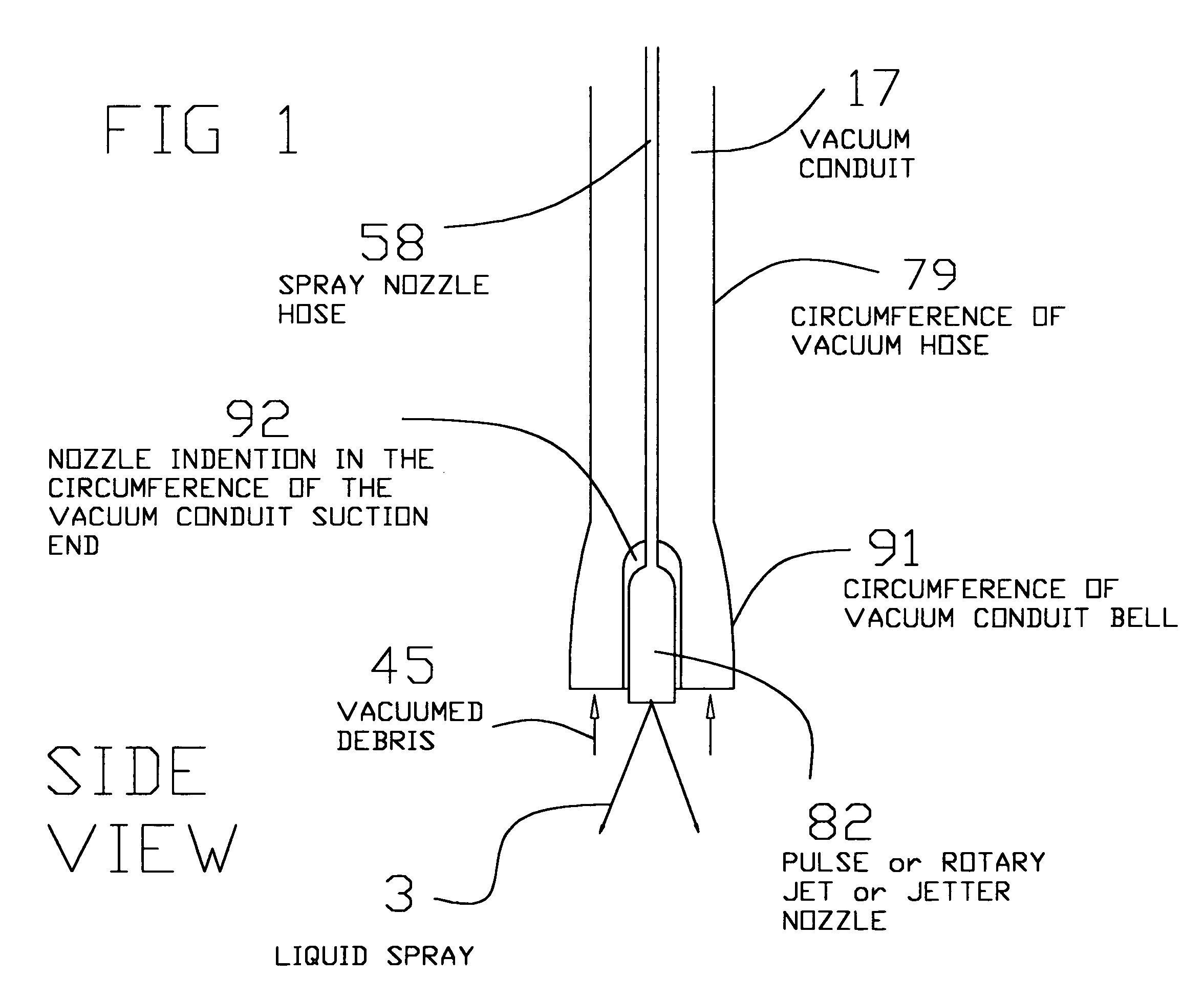

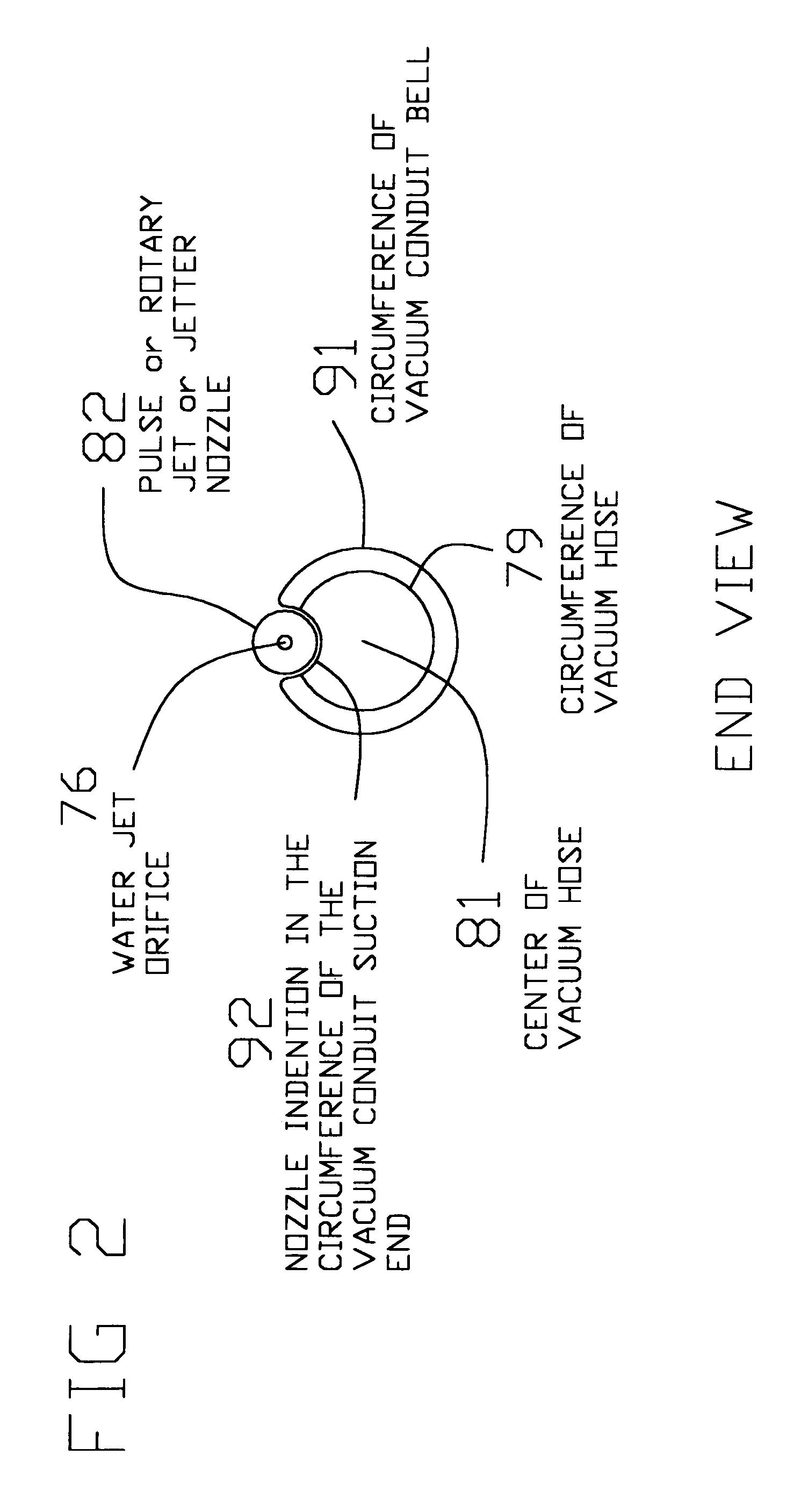

[0021] Referring now to the drawings, FIG. 1 is a cross section side elevation of a vacuum hose 17 which may be used to vacuum excavated dirt or earthen material. The circumference wall 79 of the vacuum hose 17 has been increased at the suction inlet to form a bell 91 shaped configuration. The bell circumference 91 is larger than the vacuum hose circumference 79 thus increasing the inlet area. An indention 92 is made into the bell circumference 91. The ratio between the vacuum hose circumference 79, the bell circumference 91 and the size of the indention 92, affects the area of the suction inlet of the vacuum hose 17 thus affecting the velocity of air and debris travel at that point. Various desired velocity characteristics may be achieved by manipulating the above mentioned ratios. Various debris 45 are vacuumed more effectively at different velocities thus the above mentioned ratios may be predetermined for best efficiency of a given debris 45 to be vacuumed.

[0022] The indention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com