Bottle cap

a bottle cap and automatic mounting technology, applied in the field of bottles, can solve the problems of high cost, complicated structure and operation of the automatic mounting apparatus of the bottle cap on the bottle mouth, etc., and achieve the effect of simplifying structure and operation and reducing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

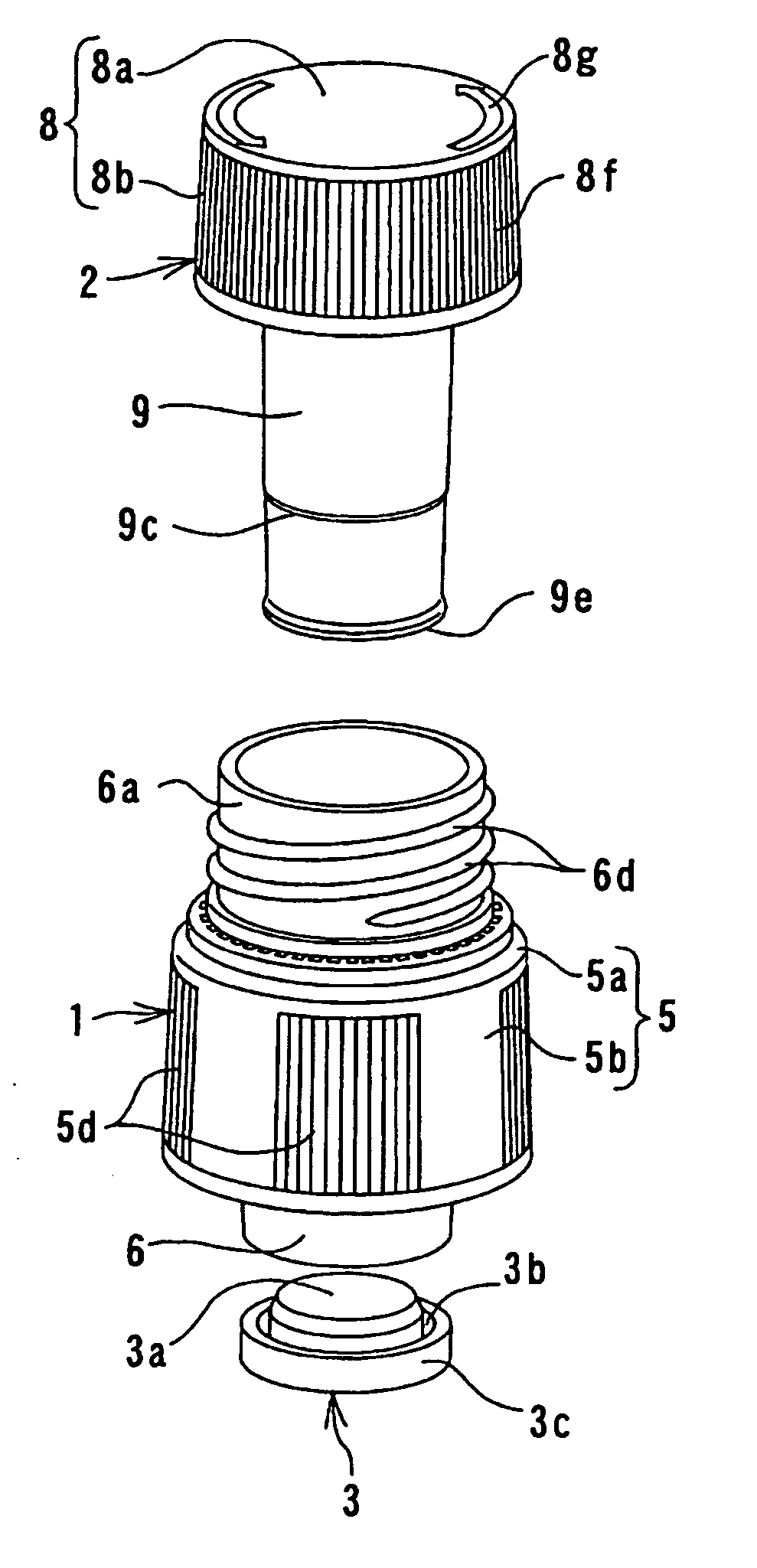

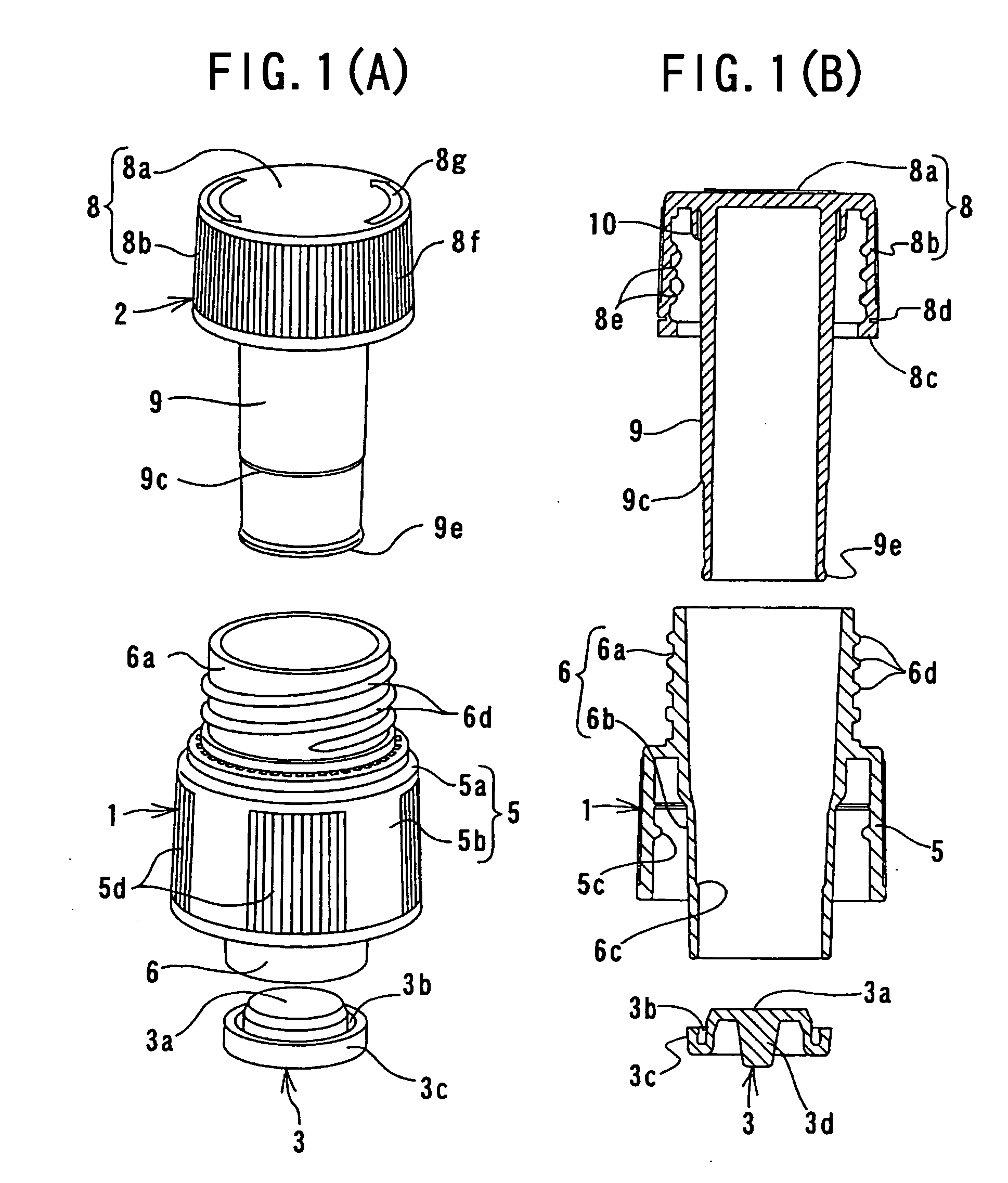

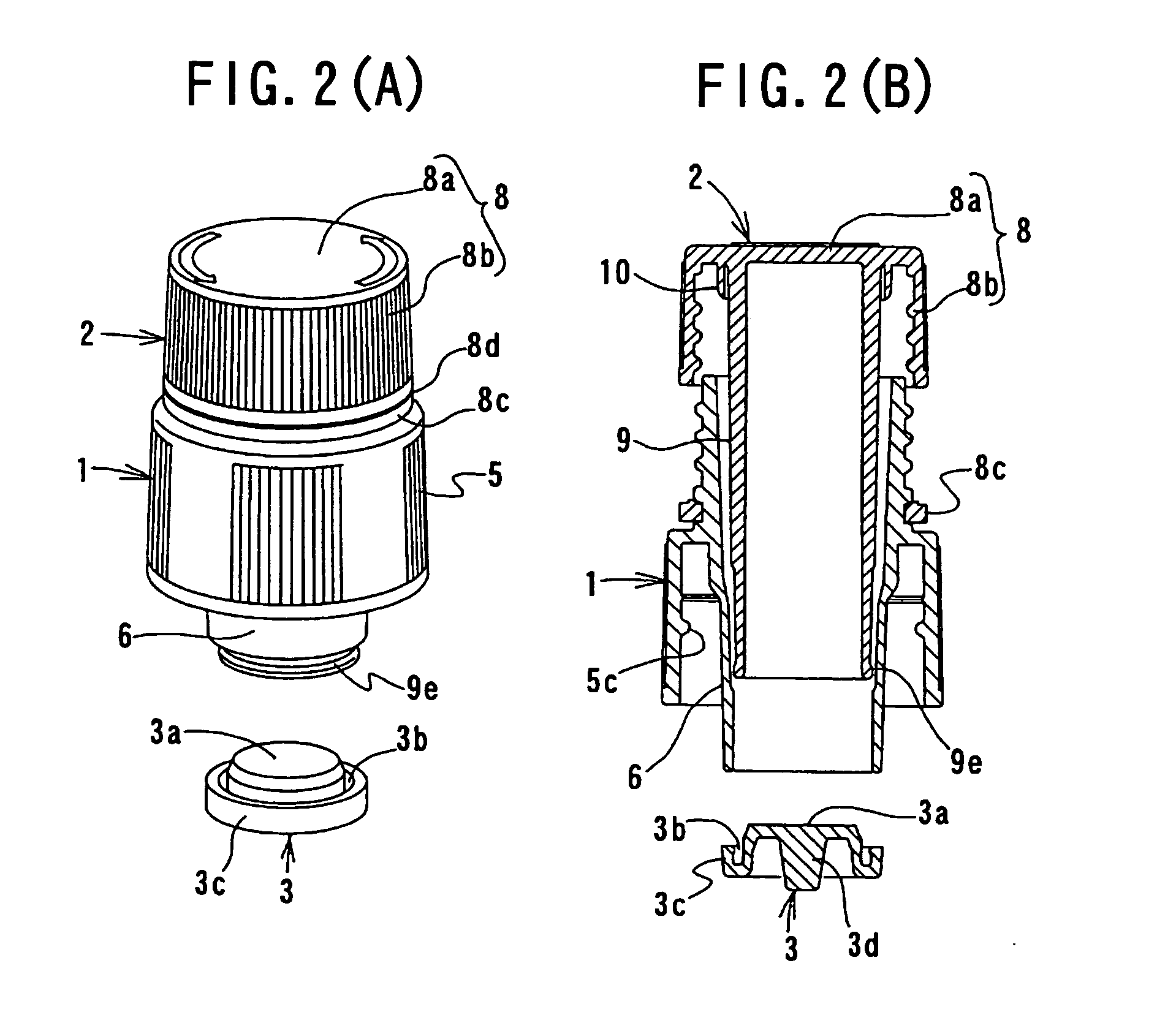

Image

Examples

first embodiment

[0067] Referring to FIGS. 5(A), 5(B), 6 and 7, there is shown a bottle cam according to a first embodiment of the present invention. The bottle cap shown includes two parts of a cap body A molded as a unitary member from a hard plastic material and an upper lid D in the form of a disk molded as a unitary member from a hard plastic material but separately from the cap body A. Further, as occasion demands, a sheet member E is applied to the upper lid D.

[0068] The cap body A is formed as a unitary molded member and includes an outer tube portion 51, a ceiling portion 52 having a circular raw material supplying entrance 52a, an inner tube portion 53 extending downwardly from the ceiling portion 52, and a bottom lid 54 at a lower end of the inner tube portion 53. A threaded portion 51c for engaging with a threaded portion 50b provided on an outer circumferential face of a mouth 50a of the bottle 50 is formed on an inner circumference of the outer tube portion 51. Further, a thin cut 55 ...

second embodiment

[0083] Now, a bottle cap according to a second embodiment of the present invention is described.

[0084] Referring to FIGS. 12(A), 12(B) and 13, the bottle cap of the second embodiment includes two parts of a cap body A molded as a unitary member from a hard plastic material and a bottom lid B molded as a separate unitary member from a hard plastic material.

[0085] The cap body A is a molded unitary member including an outer tube portion 51, a ceiling portion 52, and an inner tube portion 53 extending downwardly from the ceiling portion 52. A threaded portion 51c for engaging with a threaded portion 50b provided on an outer circumferential face of a mouth 50a of a bottle 50 such as a PET bottle shown in FIG. 15 is formed on an inner circumference of the outer tube portion 51. Further, a thin cut 55 is formed along an entire circumference at a lower circumferential edge portion of the outer tube portion 51 so that a portion of the outer tube portion 51 on the upper side with respect t...

third embodiment

[0103] Now, a bottle cap according to a third embodiment of the present invention is described with reference to FIGS. 20 to 23.

[0104] The bottle cap of the third embodiment is composed of a single part formed as a molded unitary member made of a hard plastic material and including a cap body A and an upper lid D in the form of a disk. A sheet member E is adhered to the upper lid D as occasion demands.

[0105] The cap body A is formed as a unitary member molded together with the upper lid D by simultaneous molding and includes an outer tube portion 51, a ceiling portion 52 having a circular raw material supplying entrance 52a, an inner tube portion 53 extending downwardly from the ceiling portion 52, and a bottom lid 54 at a lower end of the inner tube portion 53 similarly as in the bottle cap of the first embodiment. A threaded portion 51c for engaging with a threaded portion 50b provided on an outer circumferential face of a bottle mouth 50a of the bottle 50 is formed on an inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com