Wall construction method

a construction method and wall technology, applied in the direction of walls, constructions, building material handling, etc., can solve the problems of high implementation cost, limited scope for varying the external appearance of the brick work to suit different architectural styles and personal tastes, and relatively time-consuming types of masonry construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

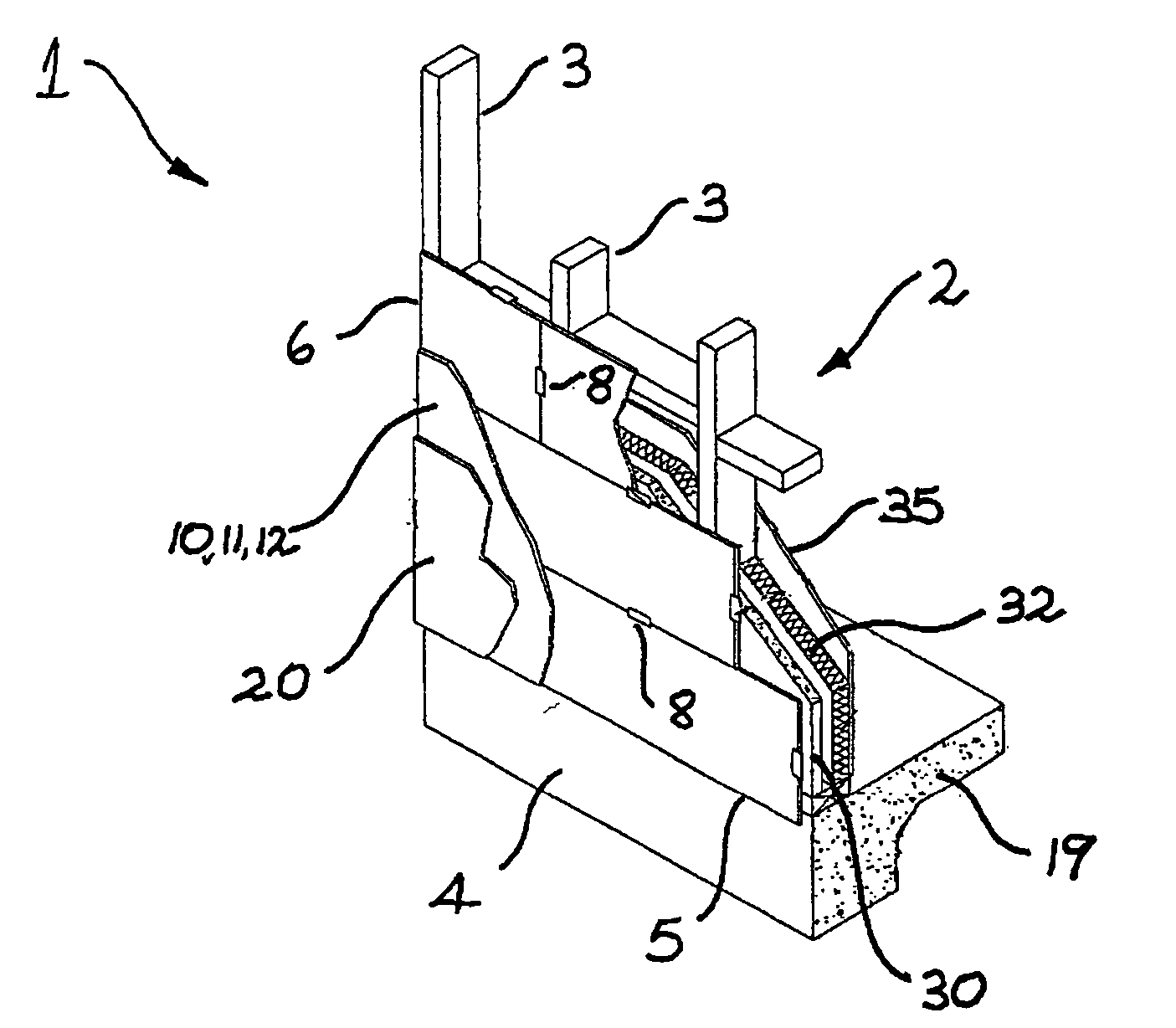

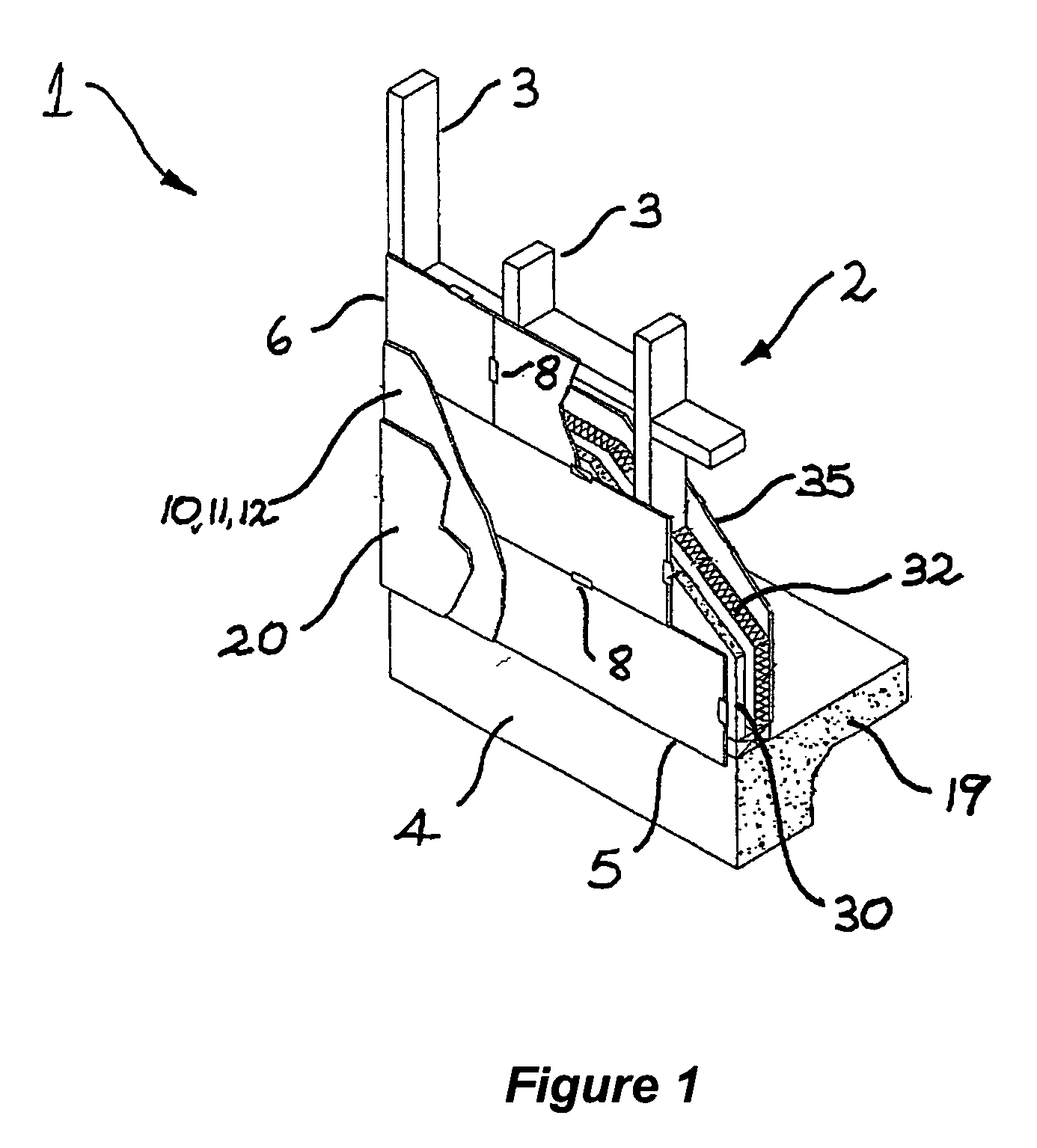

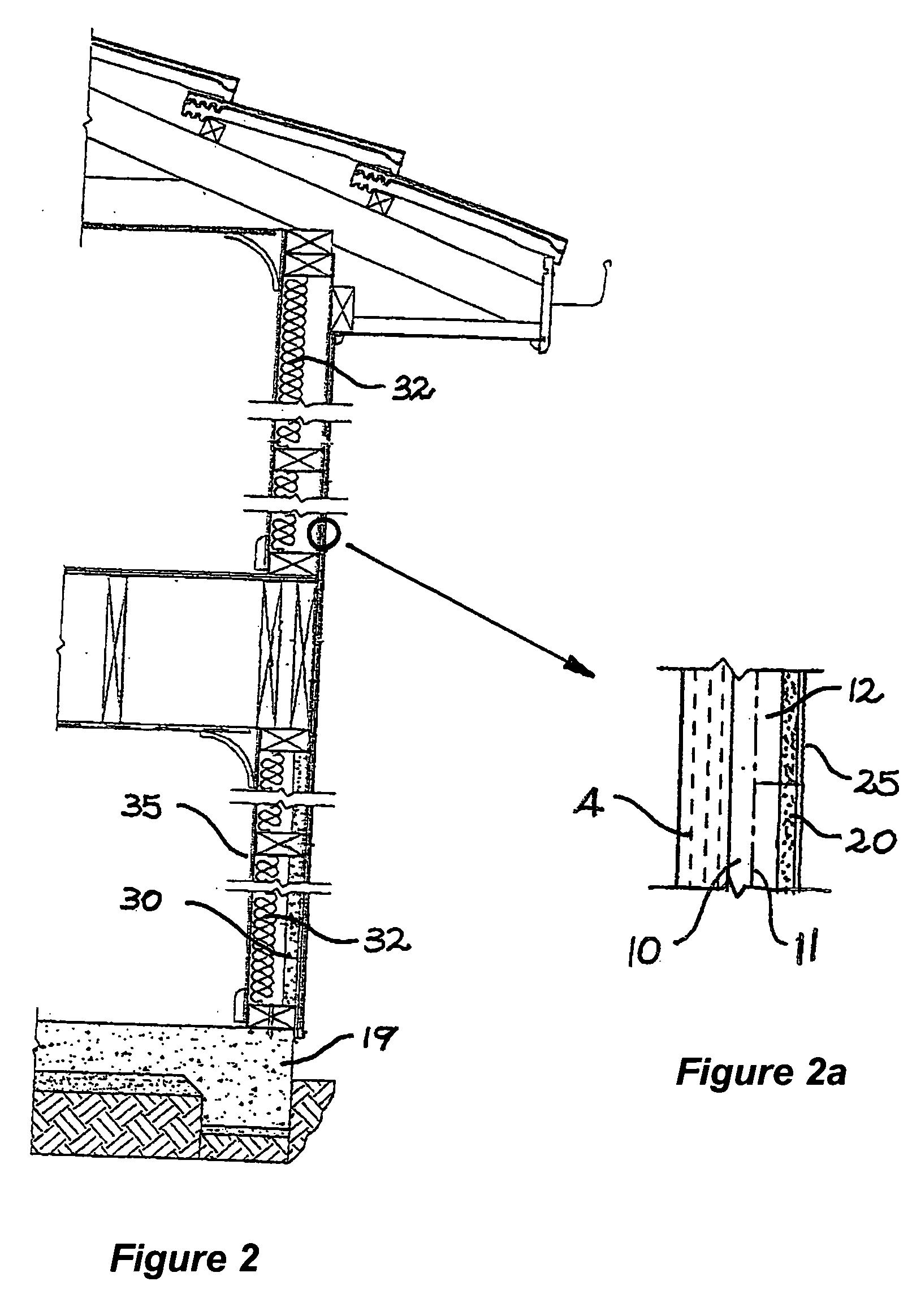

[0044] Referring initially to FIGS. 1 and 2, the invention provides a method for forming a composite wall 1. The first stage in the process involves erecting a structural frame 2 including a series of generally upright studs 3 spaced part at approximately 450 millimetre centres. The frame is preferably formed from timber, but may alternatively be formed from metal or other suitable framing materials.

[0045] The next stage of the process involves positioning a plurality of building or cladding sheets 4 over the frame in a generally horizontal orientation, such that at least a majority of the cladding sheets extend across multiple studs. The sheets are ideally staggered in a brickwork type configuration, which may be regular or irregular, as shown in FIG. 3. FIG. 4 is similar, but shows a typical installation of the sheets around an opening, such as a window or door. In cases such as this, the staggering is preserved as far as possible.

[0046] In the preferred form of the invention, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap