High flavor load particle and method of preparing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

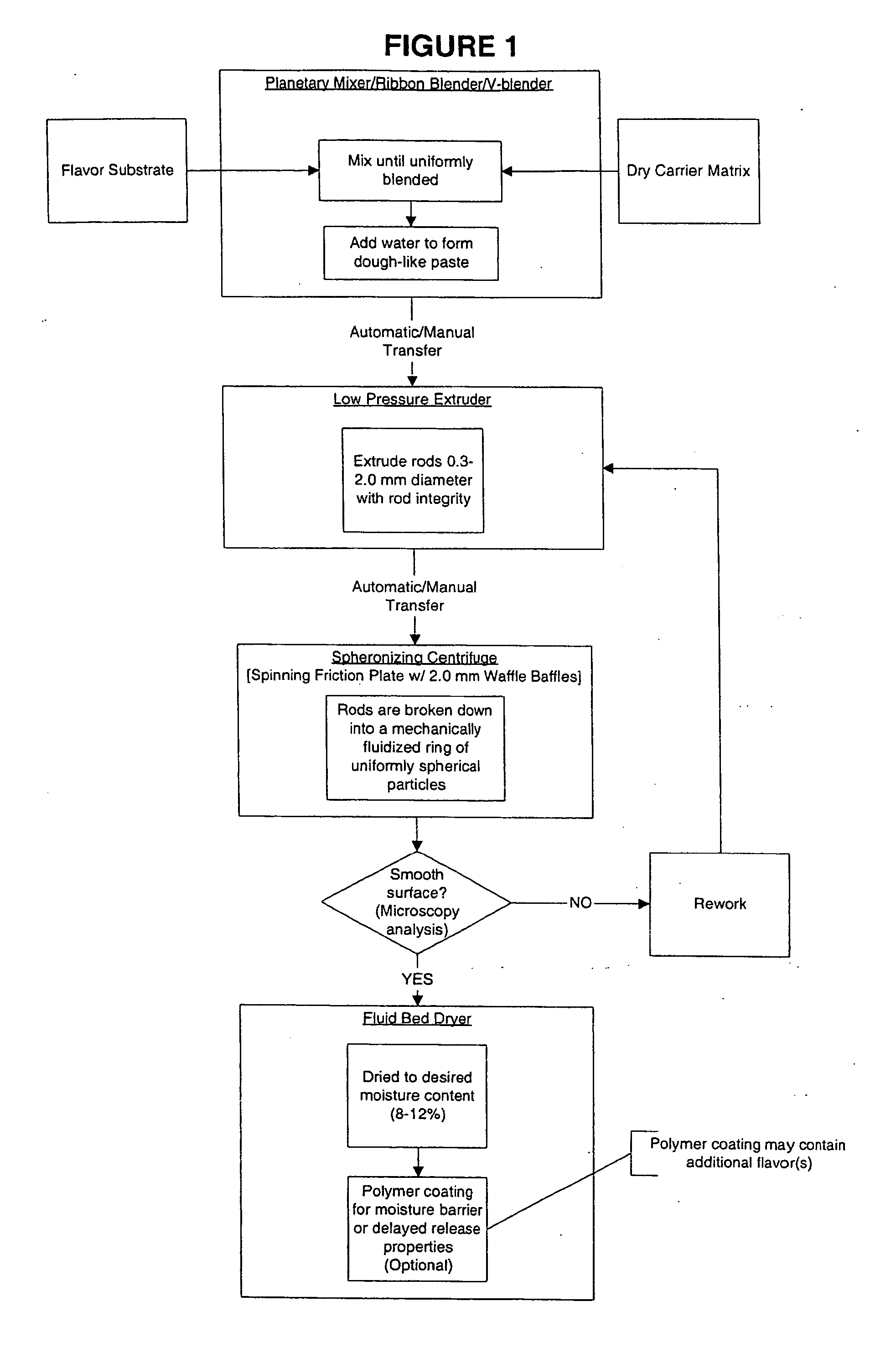

[0035] Particles of the invention can be prepared using the process that follows: [0036] 1. A hydrophilic flavor agent is applied to a dry matrix comprising of microcrystalline cellulose at a 50 / 50 w / w ratio to form a dough-like paste. [0037] 2. The dough resulting from step 1 is fed, automatically or manually, into a low-pressure extruder and extruded through a die face grid screen with a preferred grid size of 0.5 mm-1.0 mm, which defines the cross section of the particle rod. The extruder can be single or twin screw or axial twin screw, which is designed for gravity feed and low pressure extrusion or jacketed cooling of the extruder shaft. The unit has the capacity to extrude rods down to 0.3 mm with rod integrity. [0038] 3. The rods resulting from step 2 are delivered, manually or by machine, to a spheronizing unit. The spheronizer comprises a vertical cylinder with a discharge shaft or port, a circular multi baffled “friction” plate (e.g., 1 mm-5 mm disk) and a variable speed d...

example 2

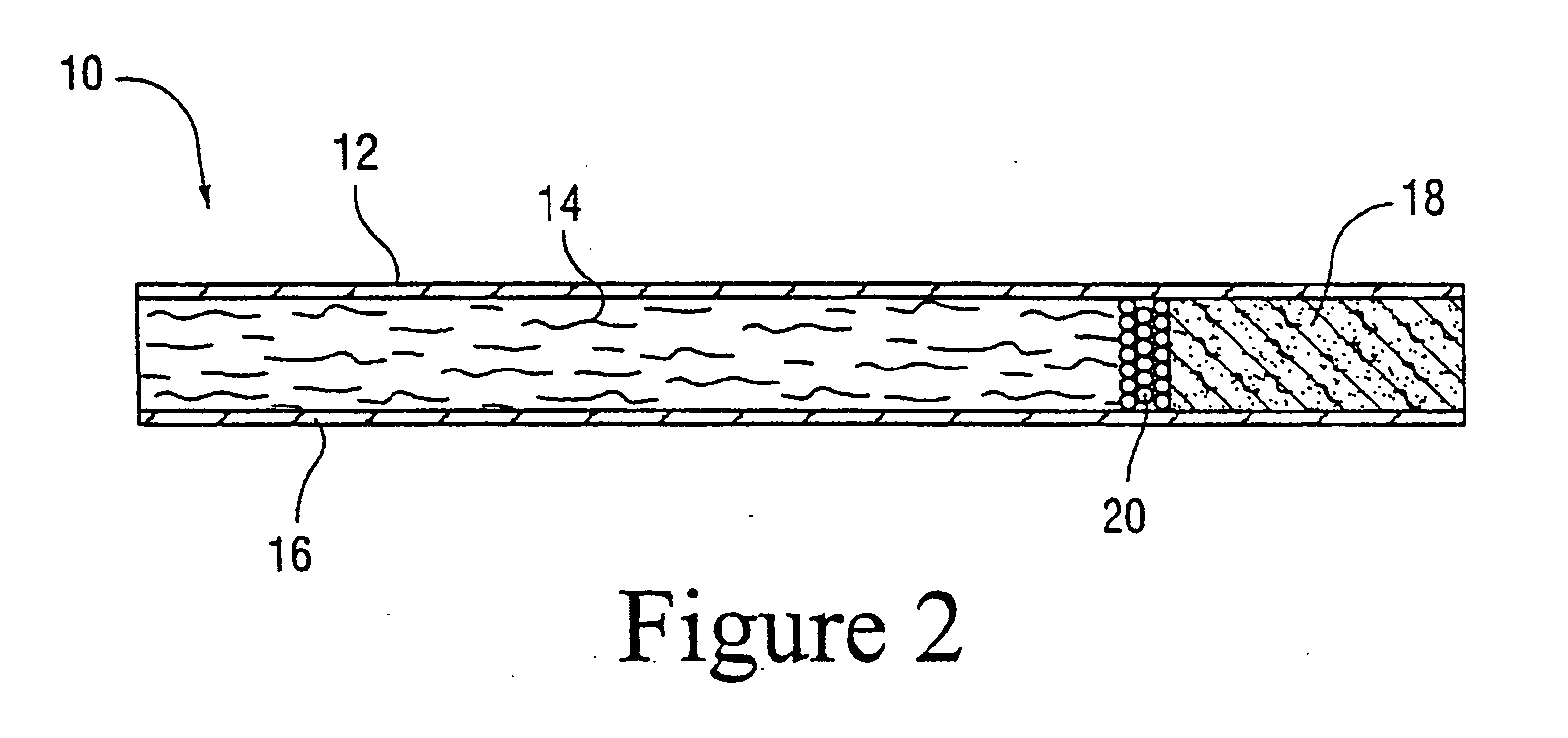

[0042] Described below is a process to deliver flavor post rod filler in a cavity beneath a cigarette filter. Theoretically, cellulose will swell, discharging flavor into entrained air flow.

Materials:

[0043] i) Tobacco Type flavor (composed of FEMA GRAS materials, the flavor can be a mix consisting of the following at the limits not to exceed the described maximum all described in percentage of the overall flavoring preparation: Acetanisole [0044] ii) Microcrystalline cellulose (Avicel PH101) (FMC Corp.) (45.45% W / W wet basis, 90.9% load dry basis). [0045] iii) Deionized water (50.00% W / W wet basis).

[0046] The process comprises the following steps: [0047] A) add Avicel and flavor to a planetary mixer; [0048] B) blend until visually uniform; [0049] C) add deionized water while mixing until visually uniform; [0050] D) extrude in a coaxial jacketed dome extruder to the specifications: 0.7 mm stainless steel dieface at an auger speed of 45 rpm inserting 10 shims at the dome contact p...

example 3

[0054] Described below is a process to deliver higher flavor load post rod filler in a cavity beneath the filter. As above, the cellulose will swell, discharging flavor into entrained air flow.

Materials:

[0055] i) Tobacco Type (composed of FEMA GRAS materials, the flavor can be a mix consisting of the following at the limits not to exceed the described maximum all described in percentage of the overall flavoring preparation: Acetanisole [0056] ii) Microcrystalline cellulose (Avicel PH101) (FMC Corp.) (45.55% W / W wet basis, 79.78% load dry basis). [0057] iii) Deionized water (45.45% W / W wet basis)

[0058] The process comprises the same steps set forth above in Example 2. The resulting spheres can be introduced into a cigarette rod in the manner described in Example 2 and flavor delivery evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com