Fluid filtration apparatus and method

a filter apparatus and fluid technology, applied in the direction of moving filter element filters, filtration separation, separation processes, etc., can solve the problems of unfavorable production and production costs of filter apparatus, and the complexity of such filters tends to drive up the price of filter apparatus and the cost of production. , to achieve the effect of less pressure drop through the filter apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

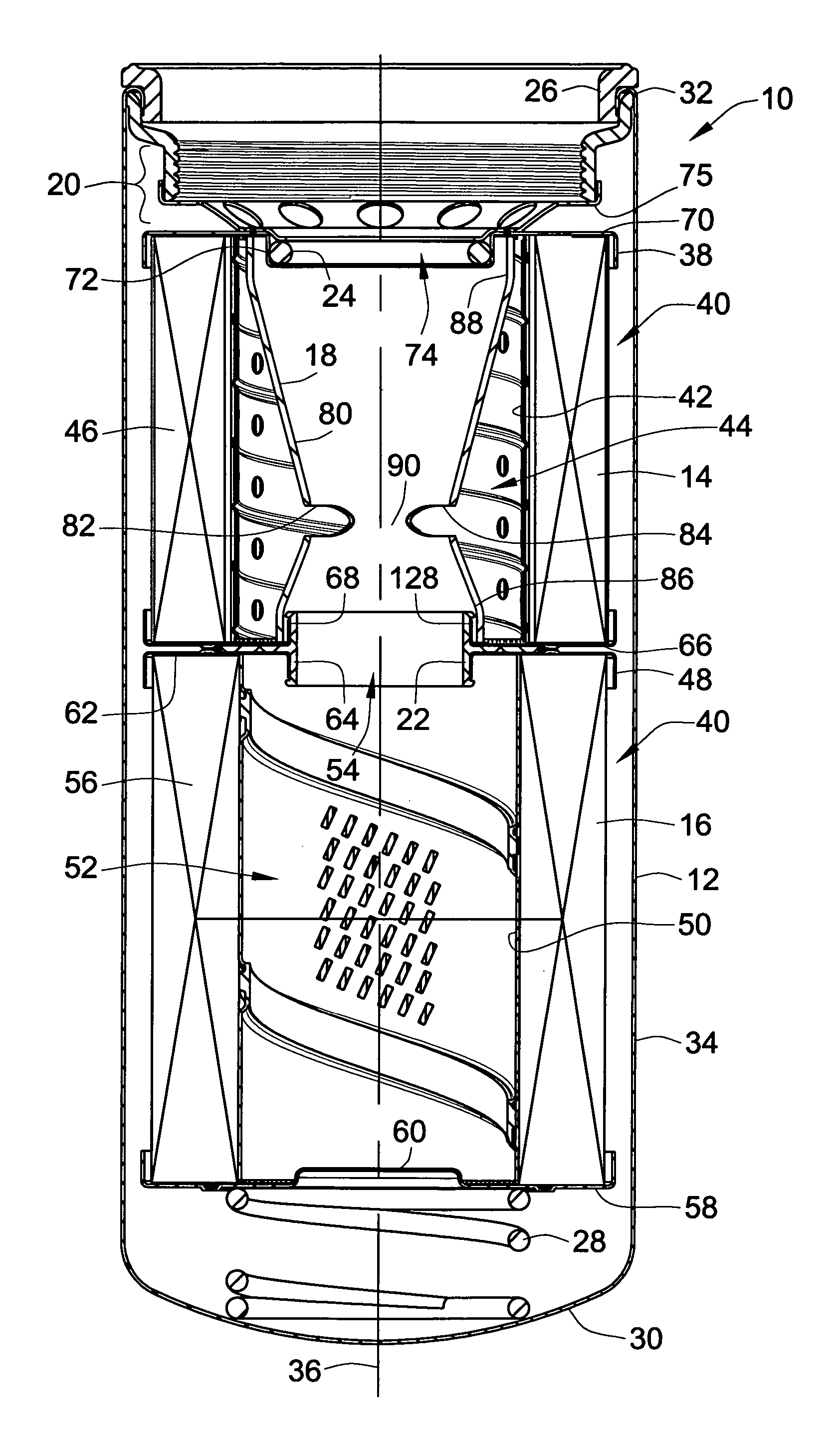

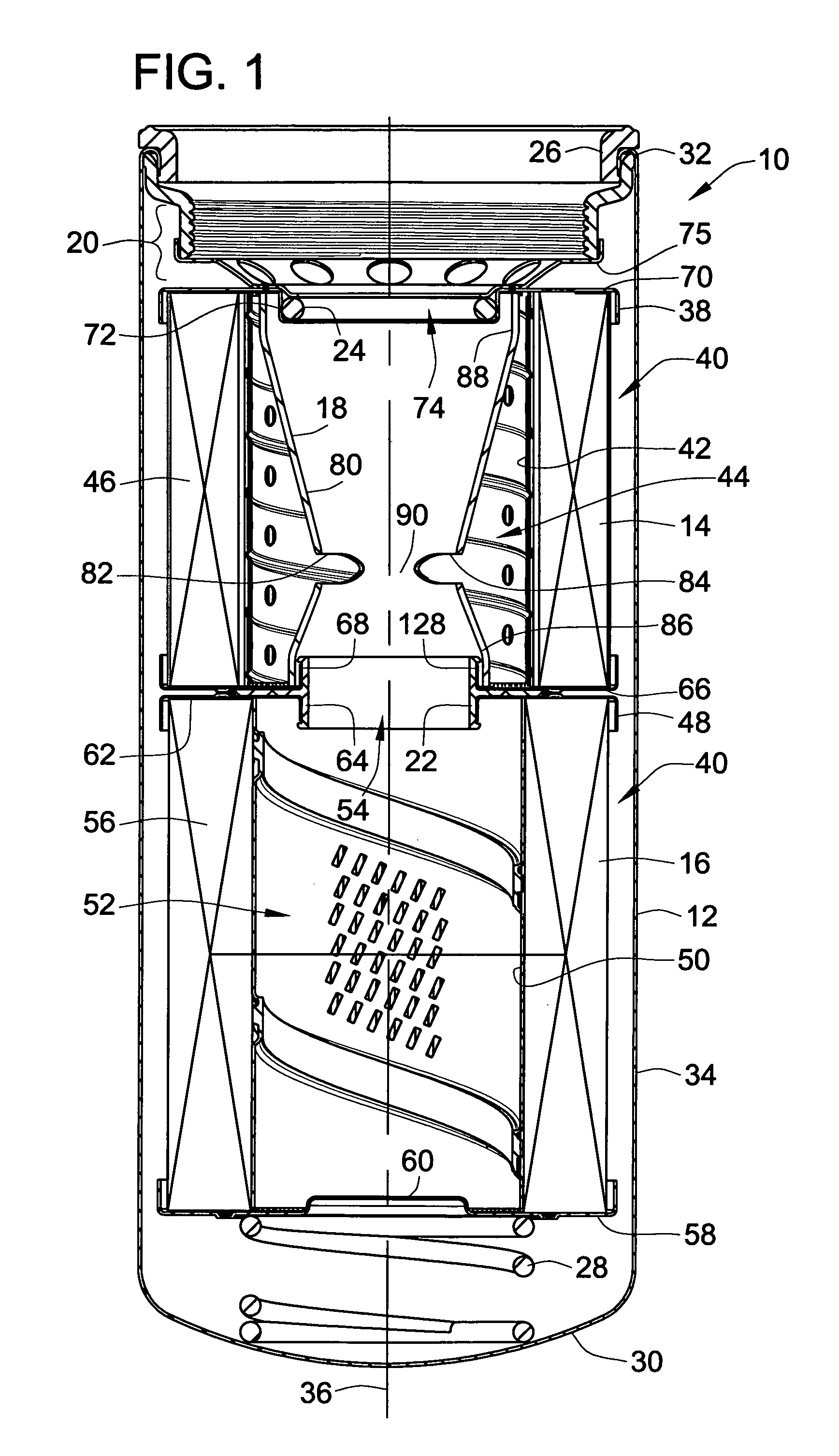

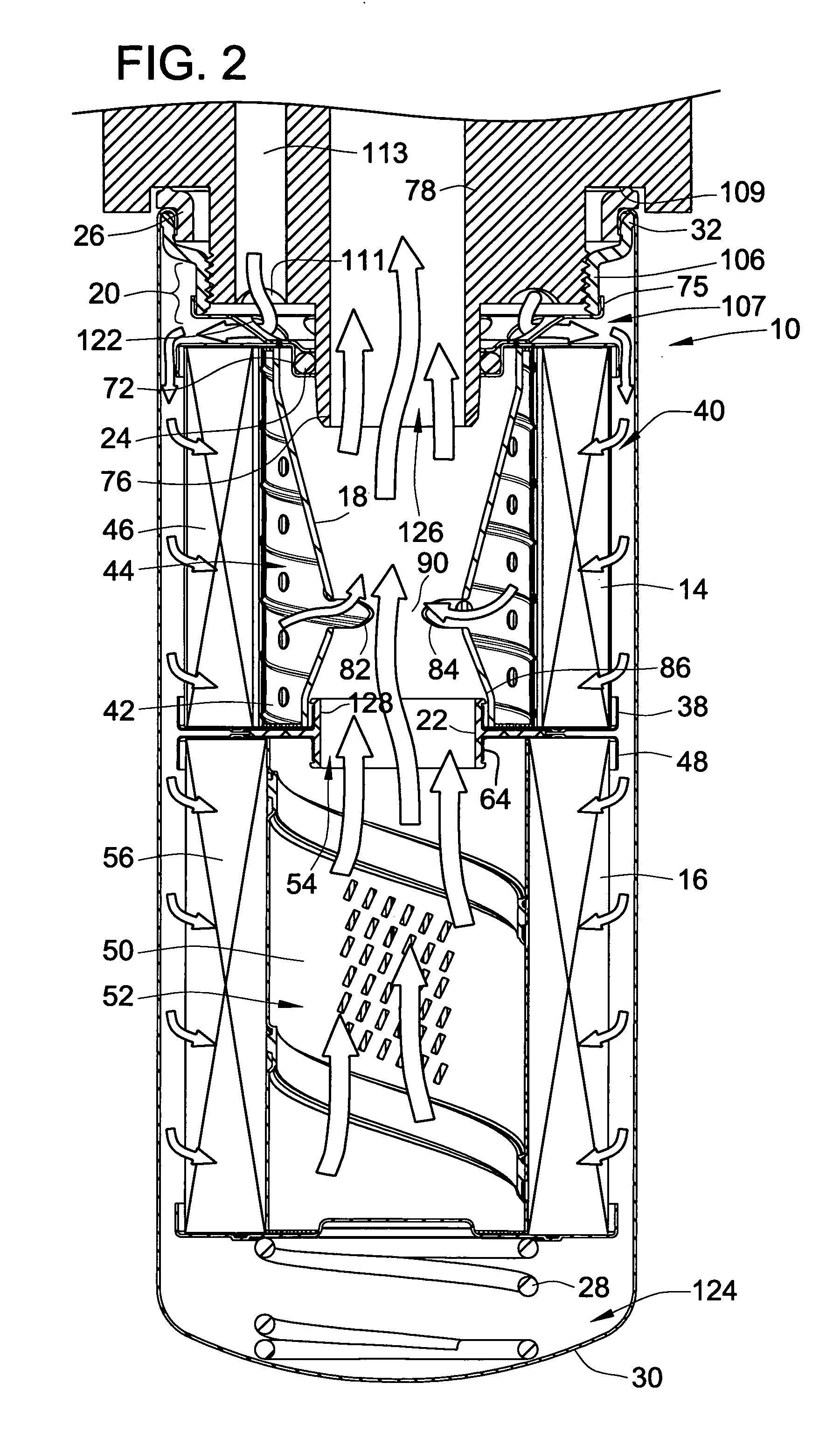

[0032]FIGS. 1 through 3 show a first exemplary embodiment of a filter apparatus, according to the invention, in the form of a spin-on filter 10. As shown in FIG. 1, the spin on filter 10 includes, a housing 12, enclosing a bypass filter 14, a full flow filter 16, a flow balancing element 18, a baseplate and spacer apparatus 20, an intermediate seal 22, an outlet seal 24, an inlet seal 26, and a helical compression spring 28. In general, FIGS. 1 and 3 show structural details of the exemplary embodiment of the spin-on filter 10, and FIG. 2 shows the manner in which fluid flows through the exemplary embodiment of the spin-on filter 10.

[0033] The housing 12 has a closed end 30 and an open end 32, joined by a cylindrical sidewall 34 defining a longitudinal axis 36 extending from the closed end 30 to the open end 32 of the housing 12.

[0034] The bypass filter 14 is disposed within the housing 12 at a point along the longitudinal axis 36 adjacent the open end 32 of the housing 12. The byp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com