Golf club shaft

a golf club and shaft body technology, applied in the field of golf club shafts, can solve the problems of affecting production efficiency, increasing the number of manufacturing steps, and significant bending stress in the grip portion of the shaft body, and achieves the effects of reducing manufacturing costs, reducing manufacturing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

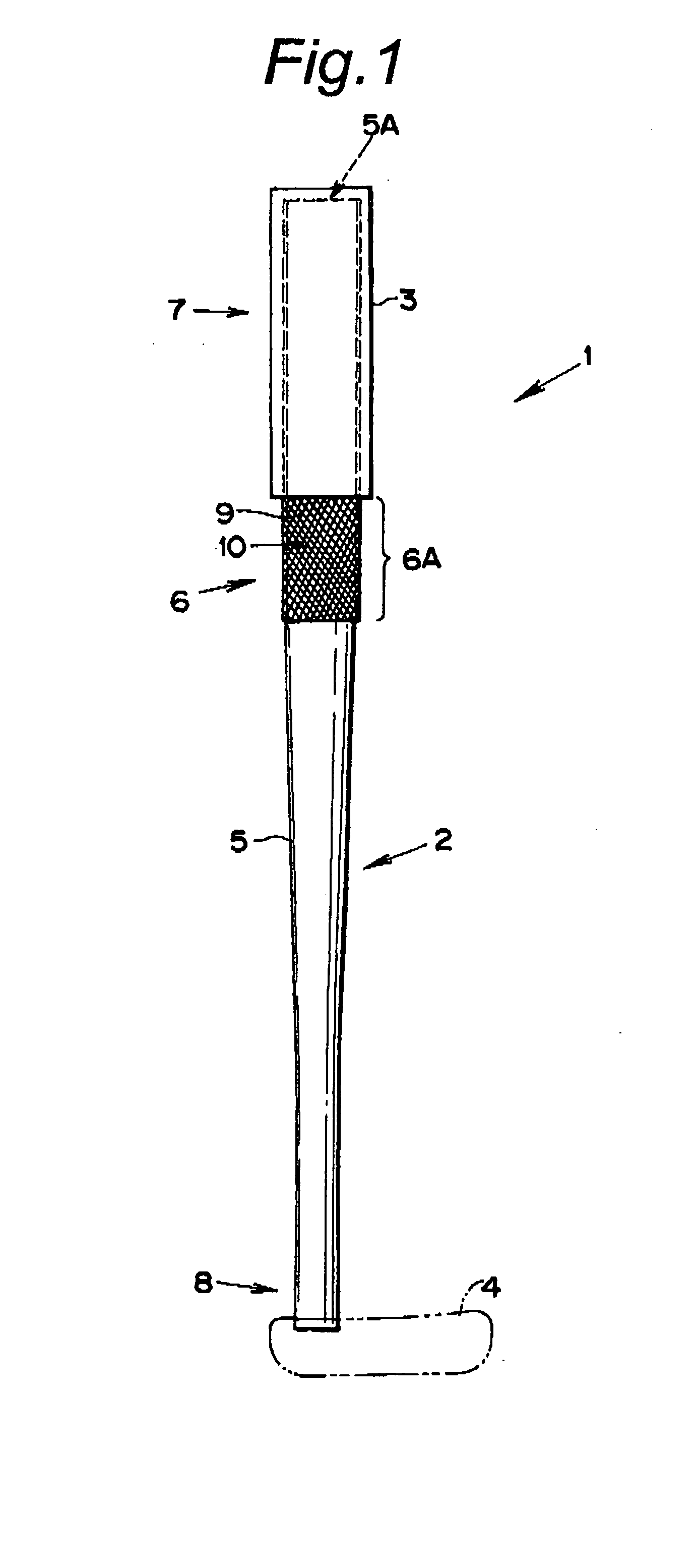

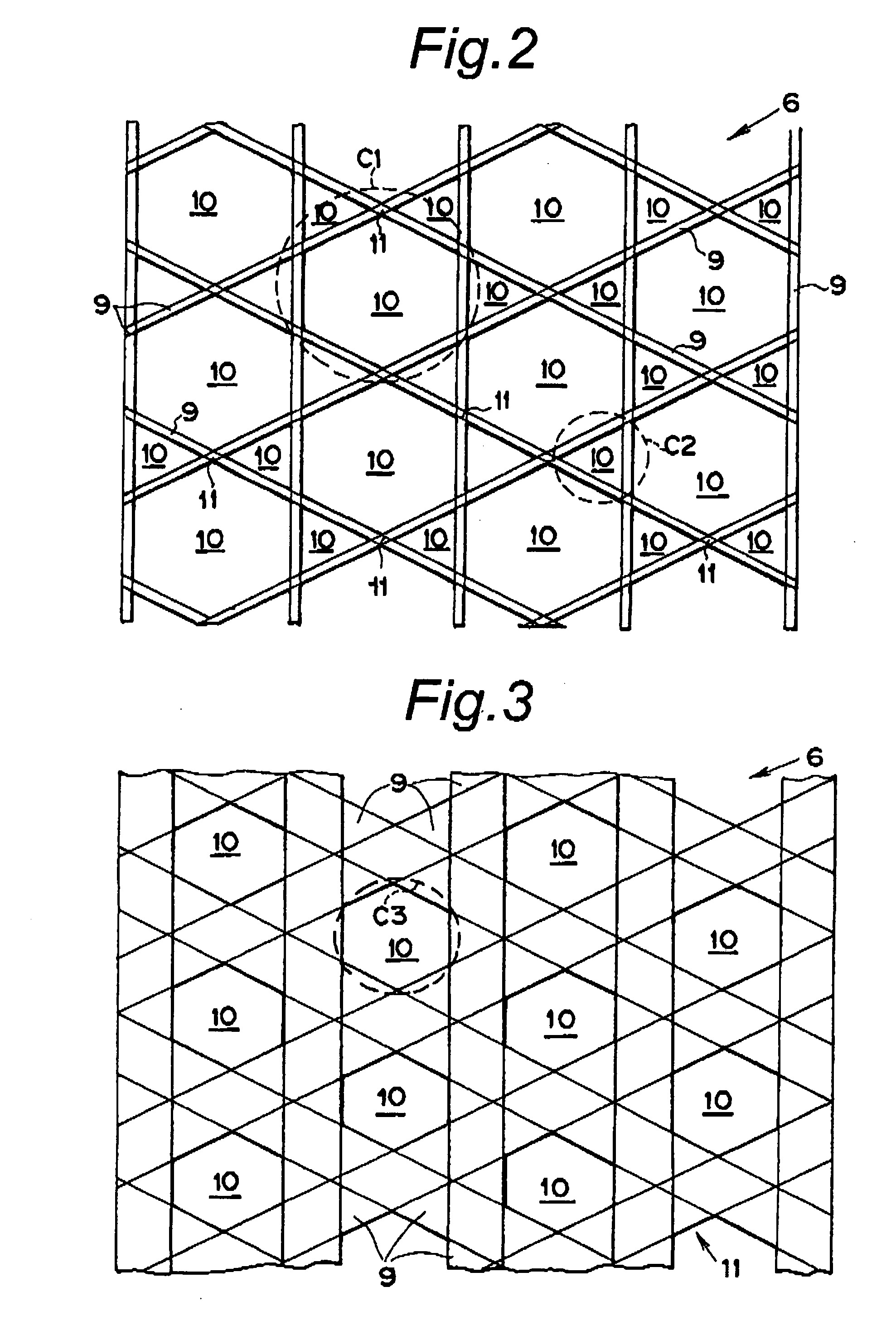

[0049] Since the structure is such that a grip is attached to a steel shaft body by interposing a fiber-reinforced plastic sheet member, that includes a fibrous reinforcing member typically having a reticular (or net-like) structure, the present invention achieves an ultra-lightweight golf club shaft, which enhances the bending strength, flattening strength and vibration damping capabilities of the grip part, and, in addition, improves grip fixability, and makes possible differentiation from the standpoint of appearance as well.

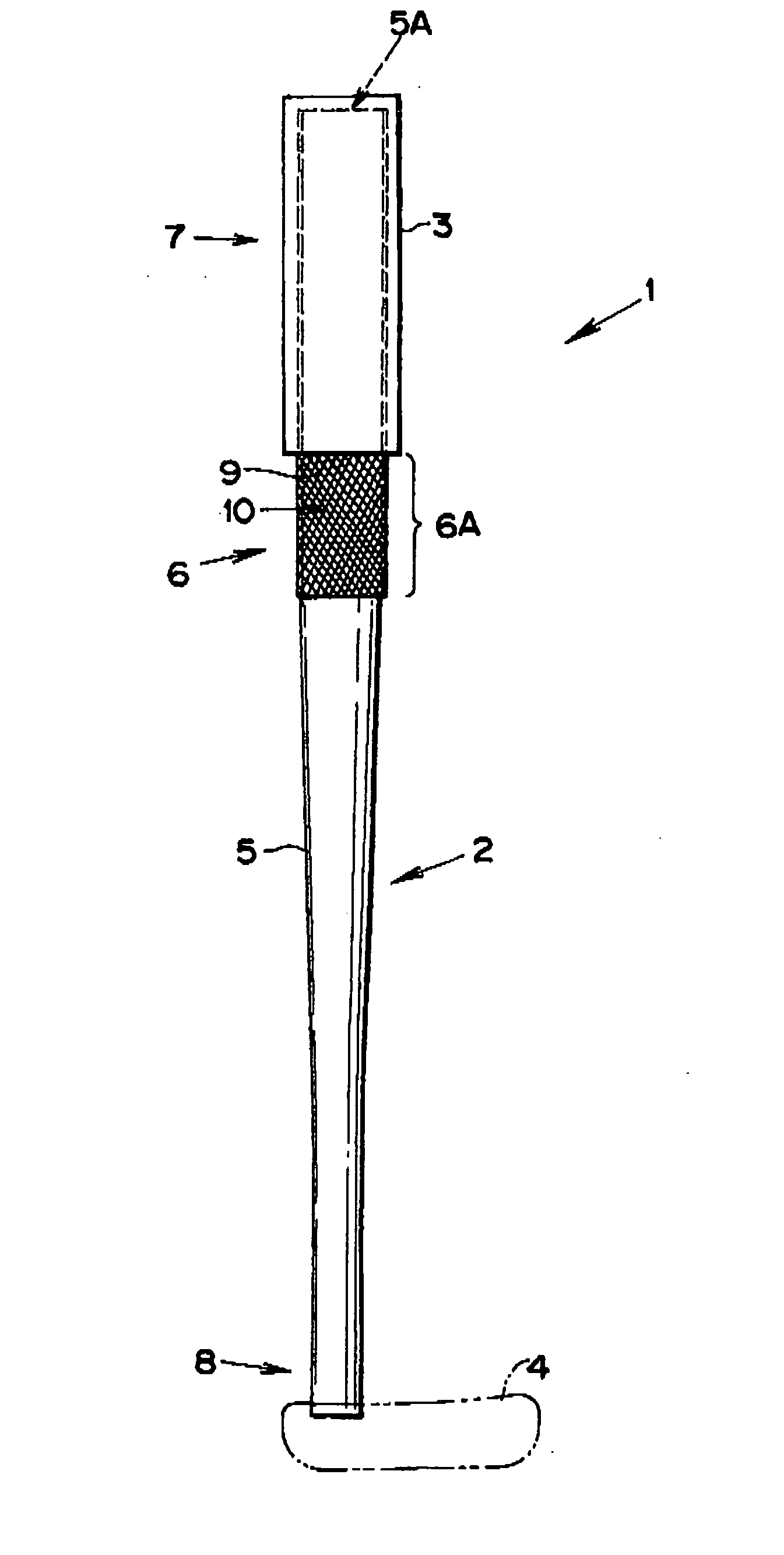

[0050]FIG. 1 is a front view of a golf club 1, and the golf club 1 has a golf club shaft 2, a grip 3 and a club head 4. The golf club shaft 2 has a shaft body 5 and a sheet member 6. The shaft body 5 is formed of steel, and the grip 3 can be mounted to the grip end 7 on one end thereof, and a club head 4 can be mounted to the club head end 8 on the other end thereof.

[0051] The sheet member 6 is secured circumferentially in one continuous turn to the grip en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com