Protected integral gas cylinder with manual on/off and flow control valve

a gas cylinder and automatic on/off technology, applied in the field of containment of gas, can solve the problems of wasting a lot of resources, and wasting a lot of resources, and achieving the effect of reducing the cost of each cylinder, saving resources, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Certain terminology is used herein for convenience only and is not to be taken as a limitation on the present invention. Further, in the drawings, the same reference numerals are employed for designating the same elements throughout the figures and certain features may be shown in somewhat schematic form.

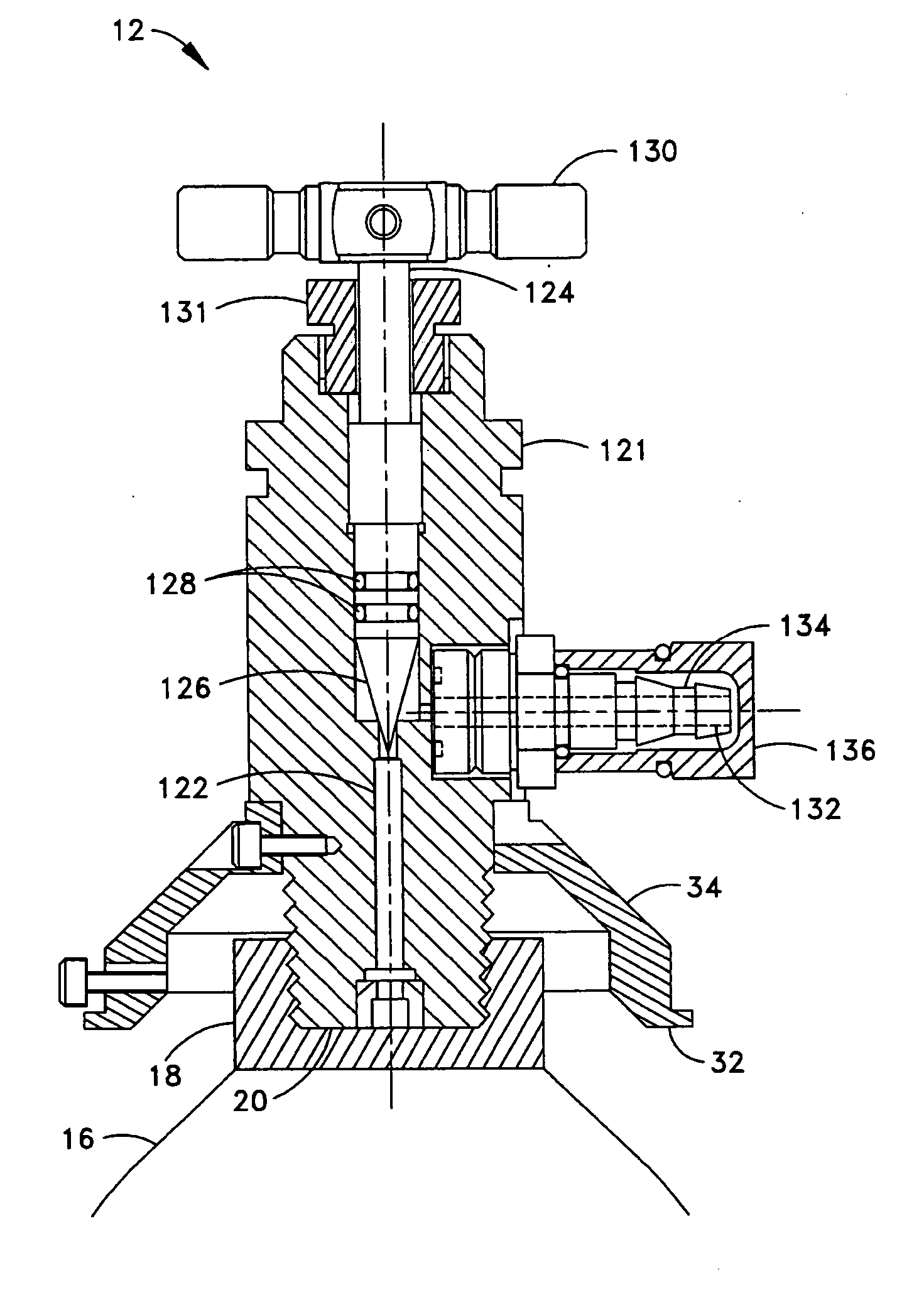

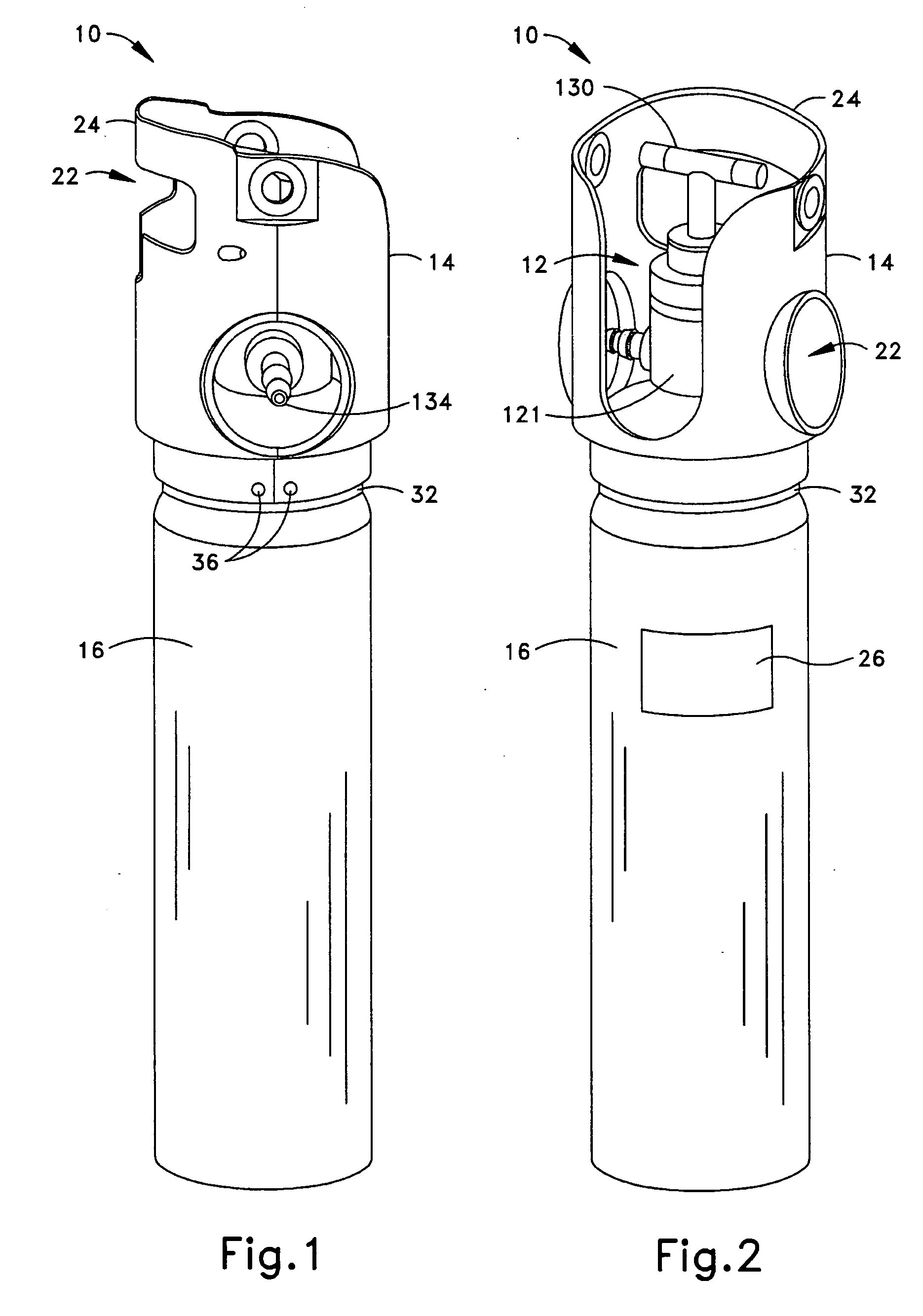

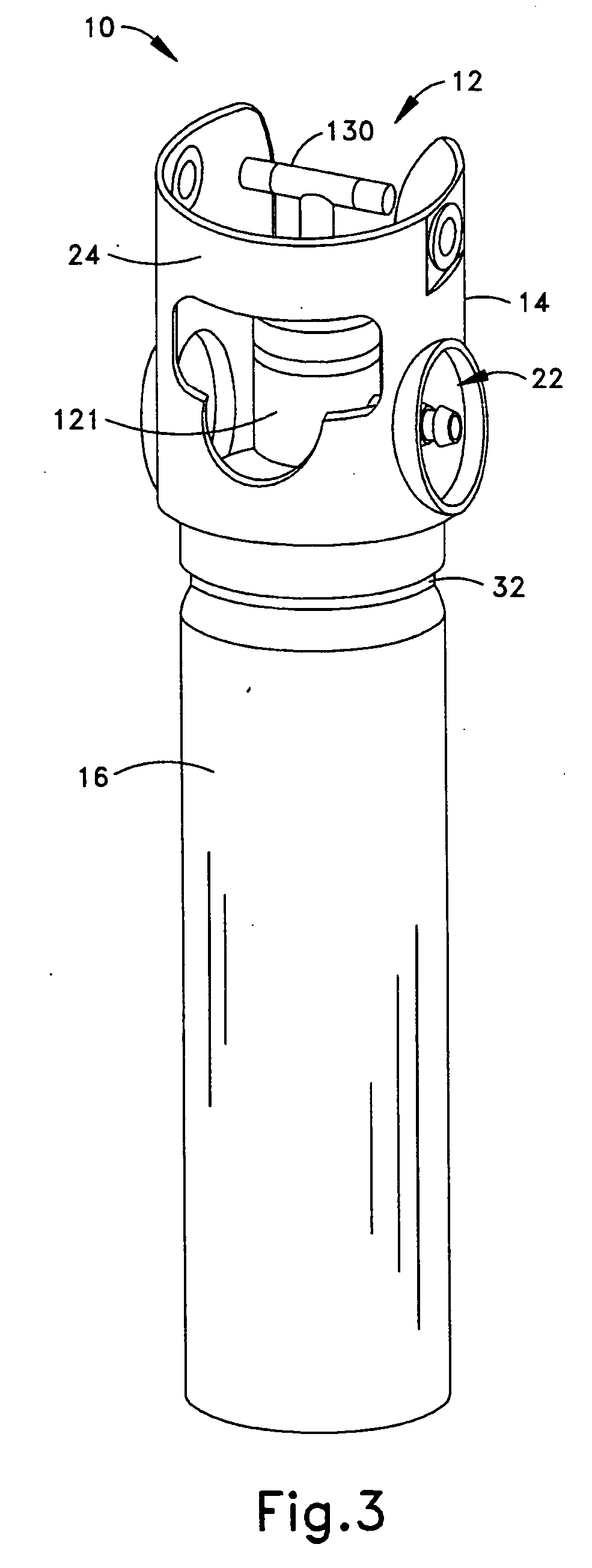

[0022] Provided is a valve and a housing for a device capable of containing pressurized contents, such as a gas cylinder, for example. The valve includes a valve body and a stem with a tapered end. Manual operation of the valve is provided by a grasp connected to a proximal end of the stem. Through manipulation of the grasp, for example, by turning the grasp, the stem can be made to move within the body. Movement of the stem within the body allows for seating and unseating the stem from the body and manual flow control of contents out of the gas cylinder to which the valve is coupled.

[0023] The device includes a common fill and discharge port. The port may be partially defi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| movement | aaaaa | aaaaa |

| impact forces | aaaaa | aaaaa |

| impact force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com