Wire and separation prep-tool

a technology of wire and separation, applied in the direction of connection, line/current collector details, electrical apparatus, etc., can solve the problem of significant amount of undesirable radio frequency (rf) transmission, and achieve the effect of minimizing the low-voltage shock of any live electrical wire and enhancing grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

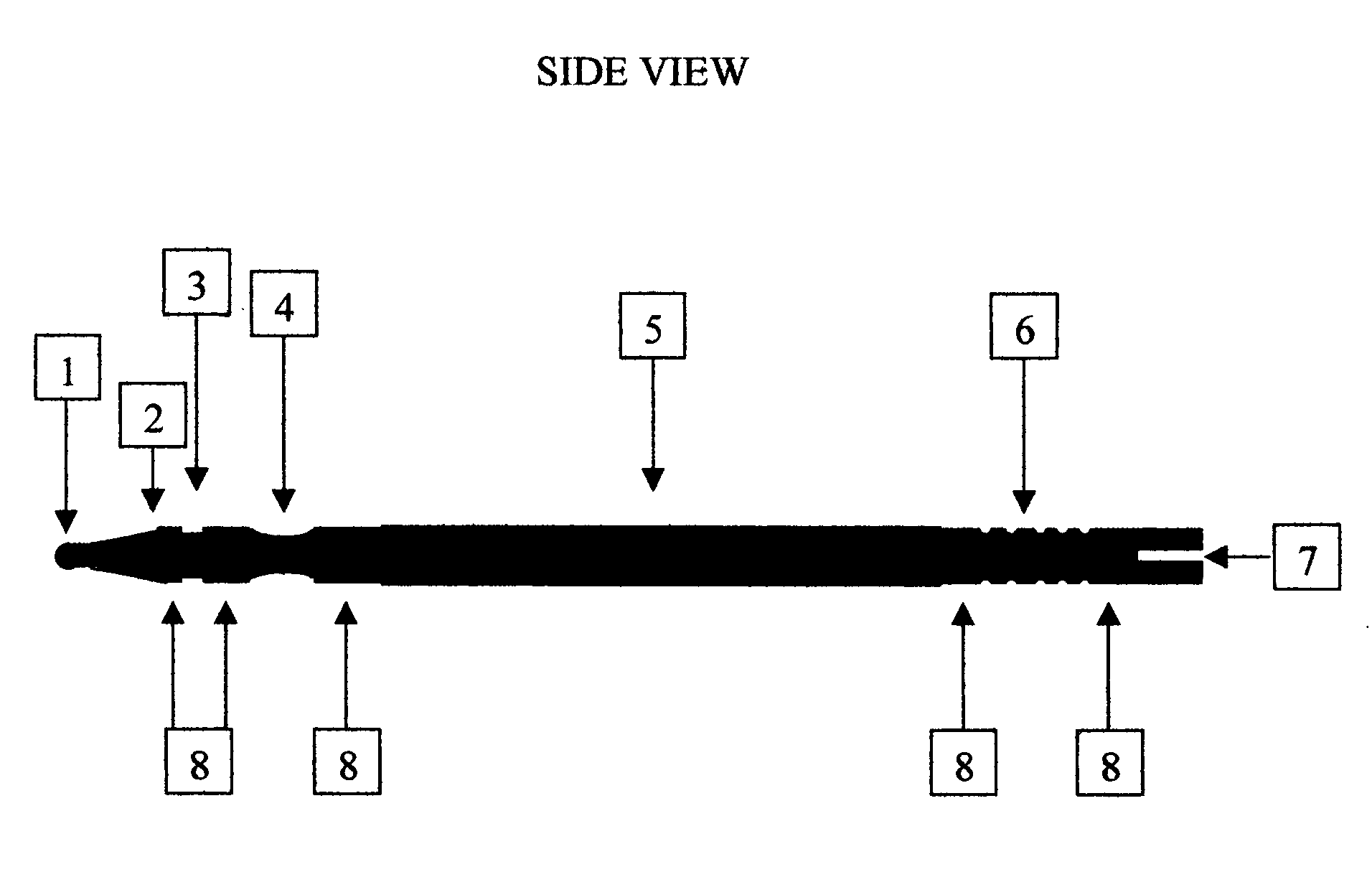

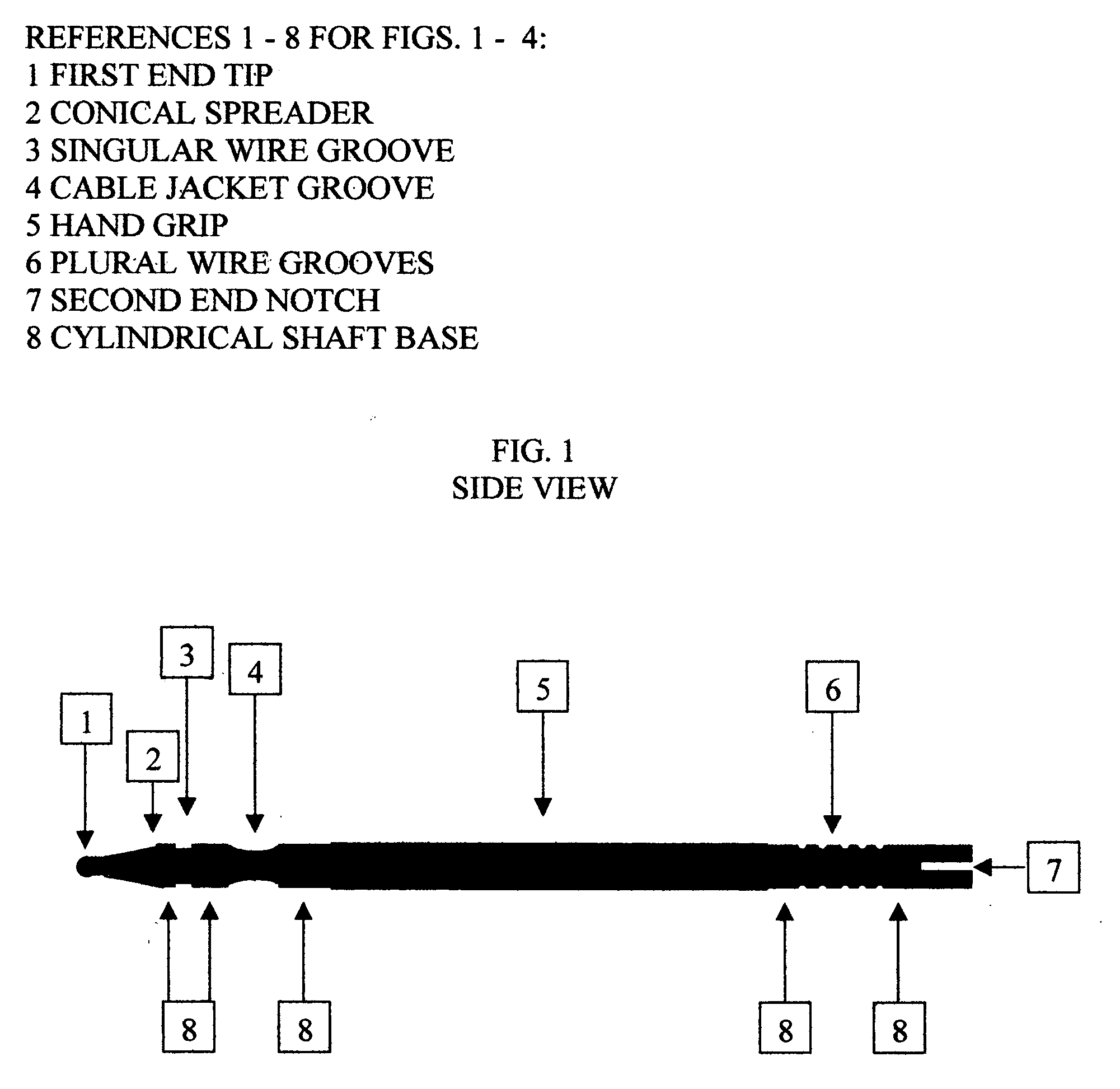

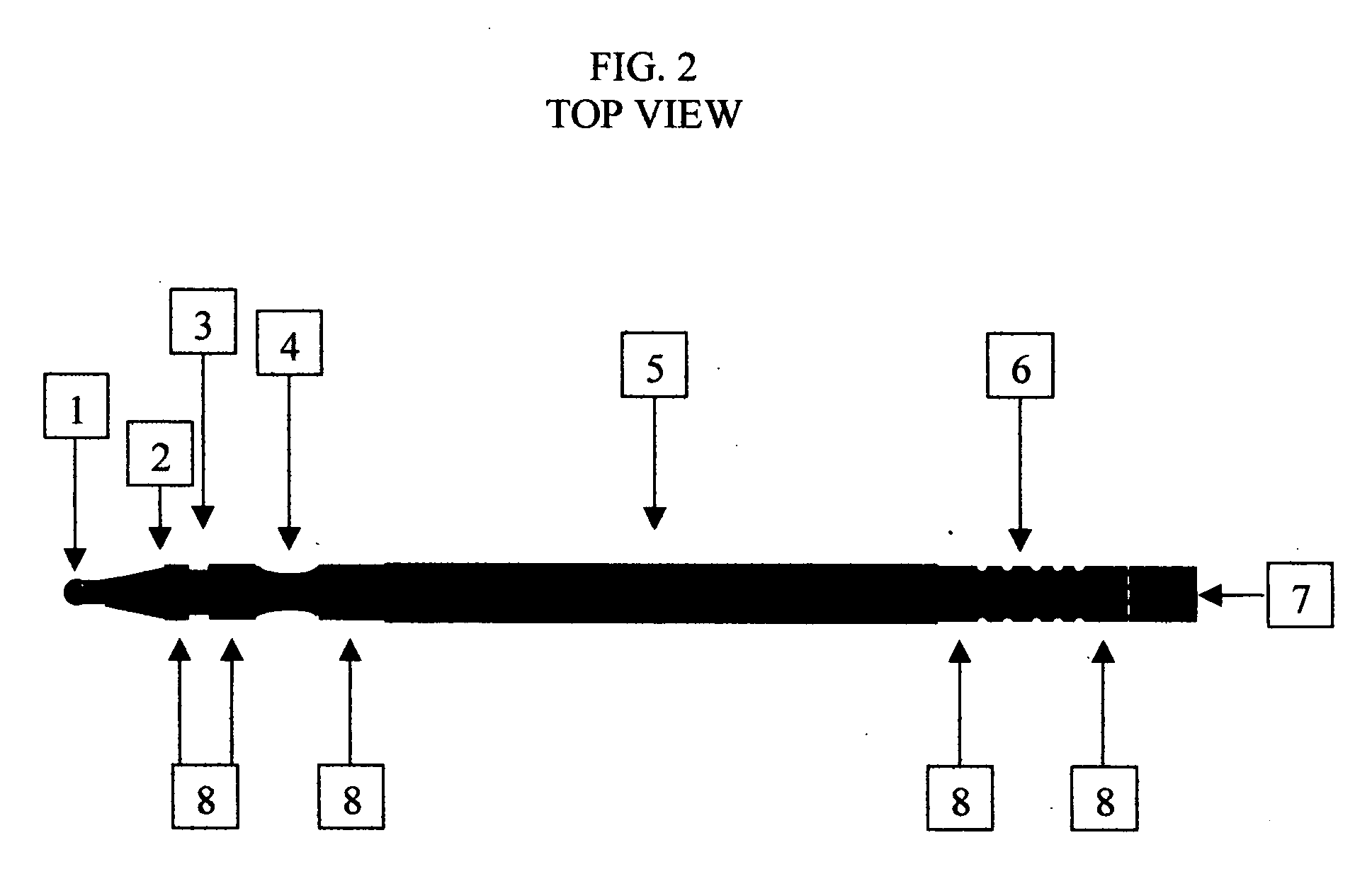

[0036] With reference to FIG. 1, a prolate cylindrical rod shaft tool having two opposing ends longitudal, one conically narrowed to a small dull pointed round mammilated end (see REF. 1), the other end perpendicularly blunt yet notched (see REF. 7). Located in between the two opposing ends is a strategic series of diametrically cut circular grooves of various depths and widths along the longitudal base shaft for specific tasks and applications (see REF. 3, 4, 6), along with an adhering concentric insulating tubular hand grip located in the middle section (see REF. 5).

[0037] This tool is a hand tool. The tool's length is 5.1″ (″=inches) and has a maximum diameter of 0.25″ except less where strategically grooved diametrically. Also with reference to FIG. 1, REF. 1, 2, 3, 4, 6, the prolate cylindrical rod shaft longitudal tool has five (5) subparts described below able to collectively perform six (6) distinct and different tasks.

SUBPARTFIG. / REF.TASKSubpart 1:FIG. 1, REF. 1:First En...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com