Helmet face shield

a technology for helmets and shields, applied in the field of helmet shields, can solve the problems of affecting the vision of riders, adding to the manufacturing cost of the face shield assembly, and being difficult to see without a rather bulky perimeter frame, so as to improve the anti-condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

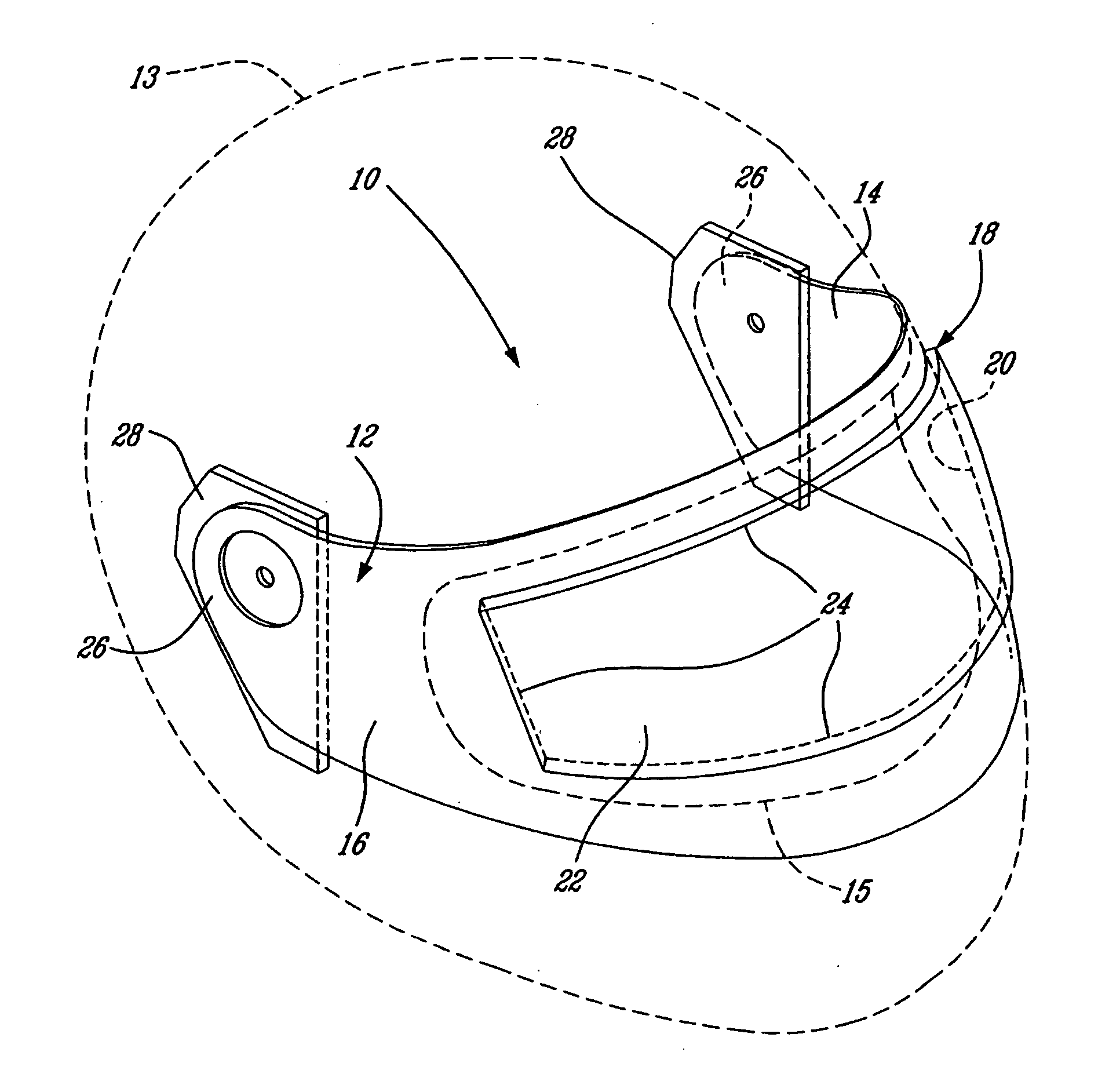

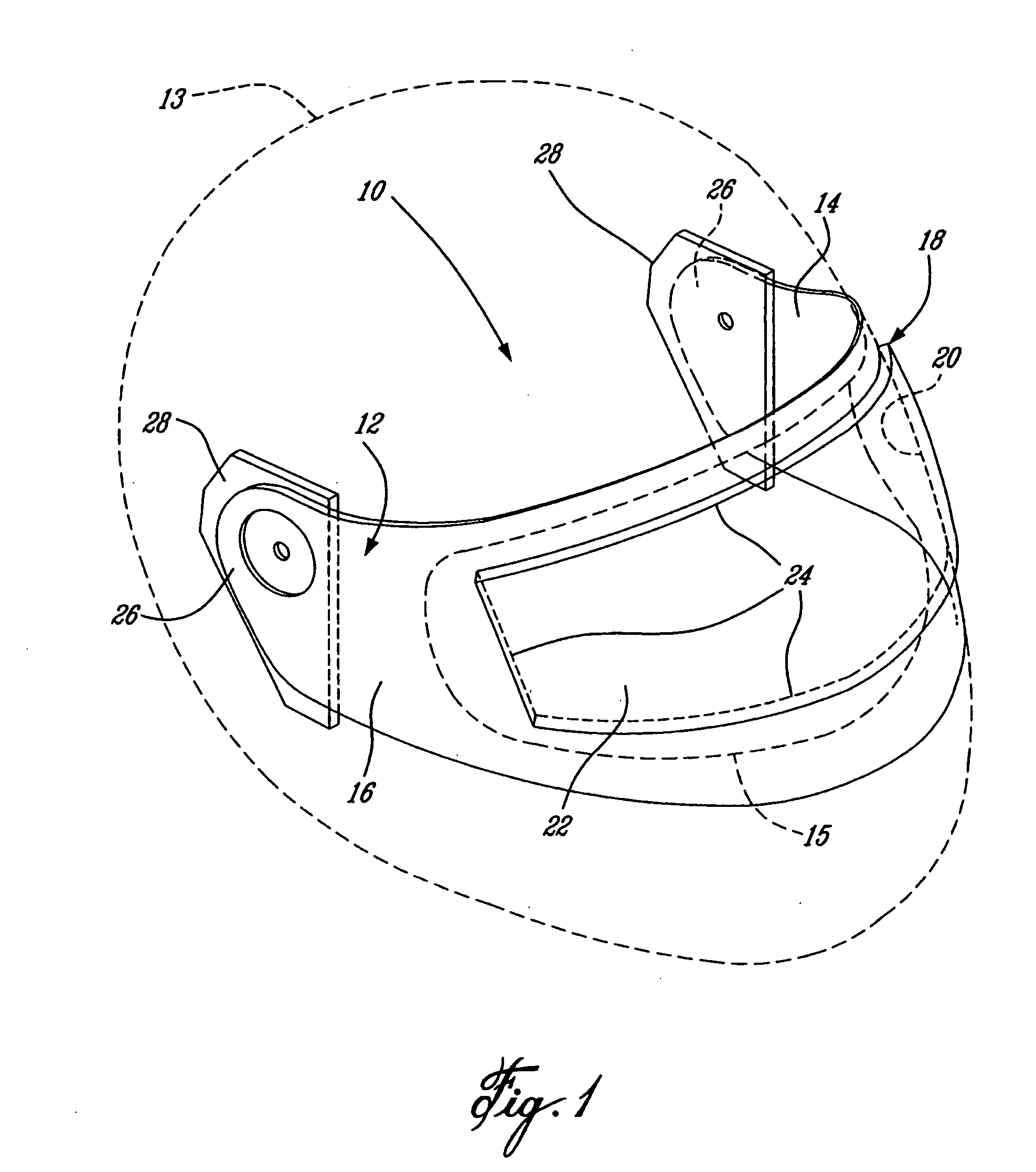

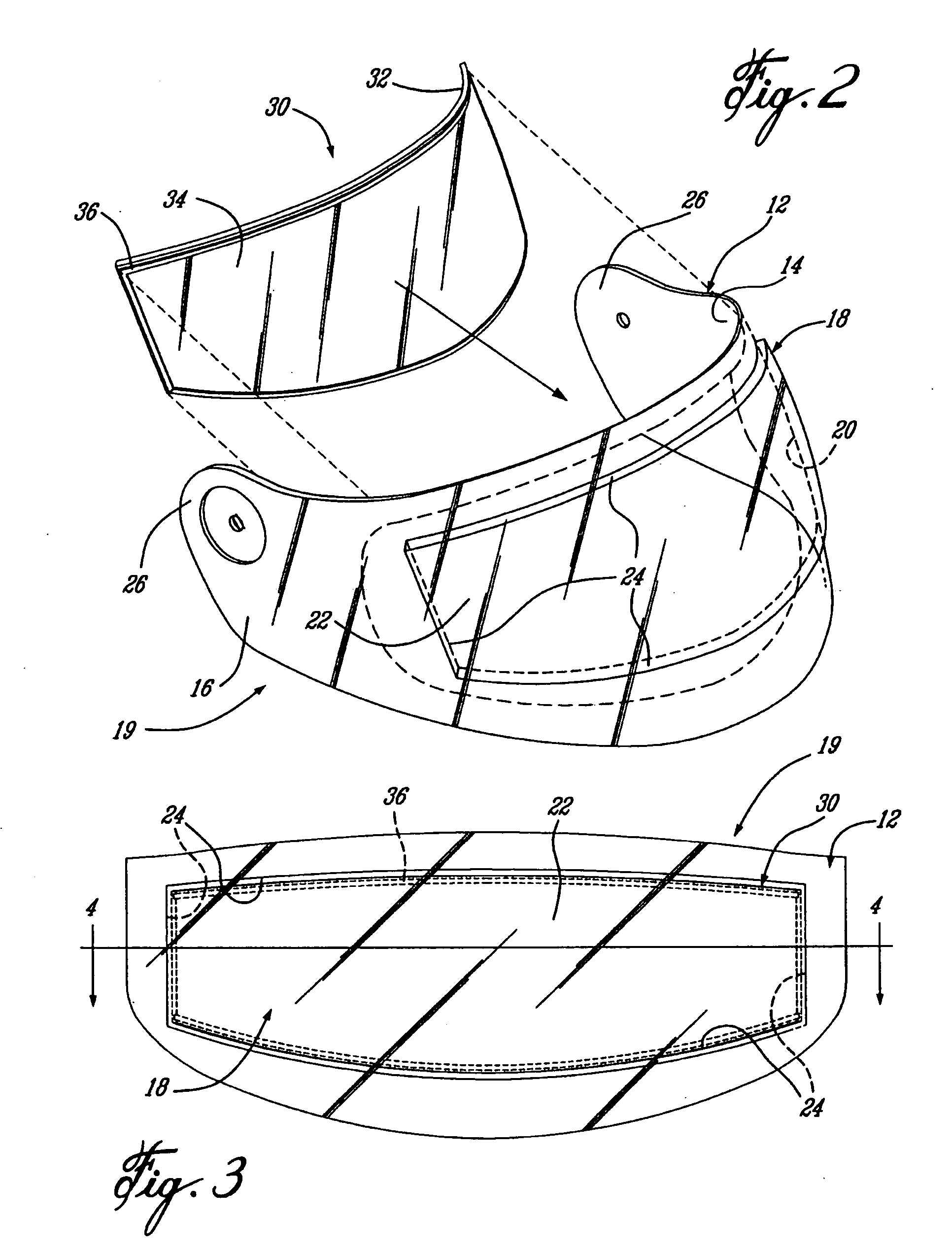

[0018] Referring to FIG. 1, the face shield 10 is adapted to be engaged to, and used with, headgear such as a protective helmet 13 as conventionally used for motorcycle riding, snowmobiling, flying and the like. The face shield 10 is also adapted for use with other protective headgear comprising a transparent face shield, such as paintball masks for example. The face shield 10 comprises primarily a generally transparent main lens 12, thereby providing a single pane lens that does not require a perimeter frame for support or engagement to the protective helmet 13. The main lens 12 is preferably a moulded plastic one-piece element, having a thickness of approximately 2 mm (about 0.07874 inches). The main lens 12 is preferably injection moulded, however other manufacturing techniques could also be used, such as drape or vacuum moulding for example. One skilled in the art will also appreciate that the main lens 12 can have a non-uniform thickness throughout. Particularly, as is known in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com