Electrically controlled solid propellant

a solid propellant, electric control technology, applied in the direction of pressure gas generation, explosives, weapons, etc., can solve the problems of not extinguishing as quickly, propellants providing none of their own energy, and prior art propellants suffering from two significant drawbacks, so as to achieve the effect of ensuring regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

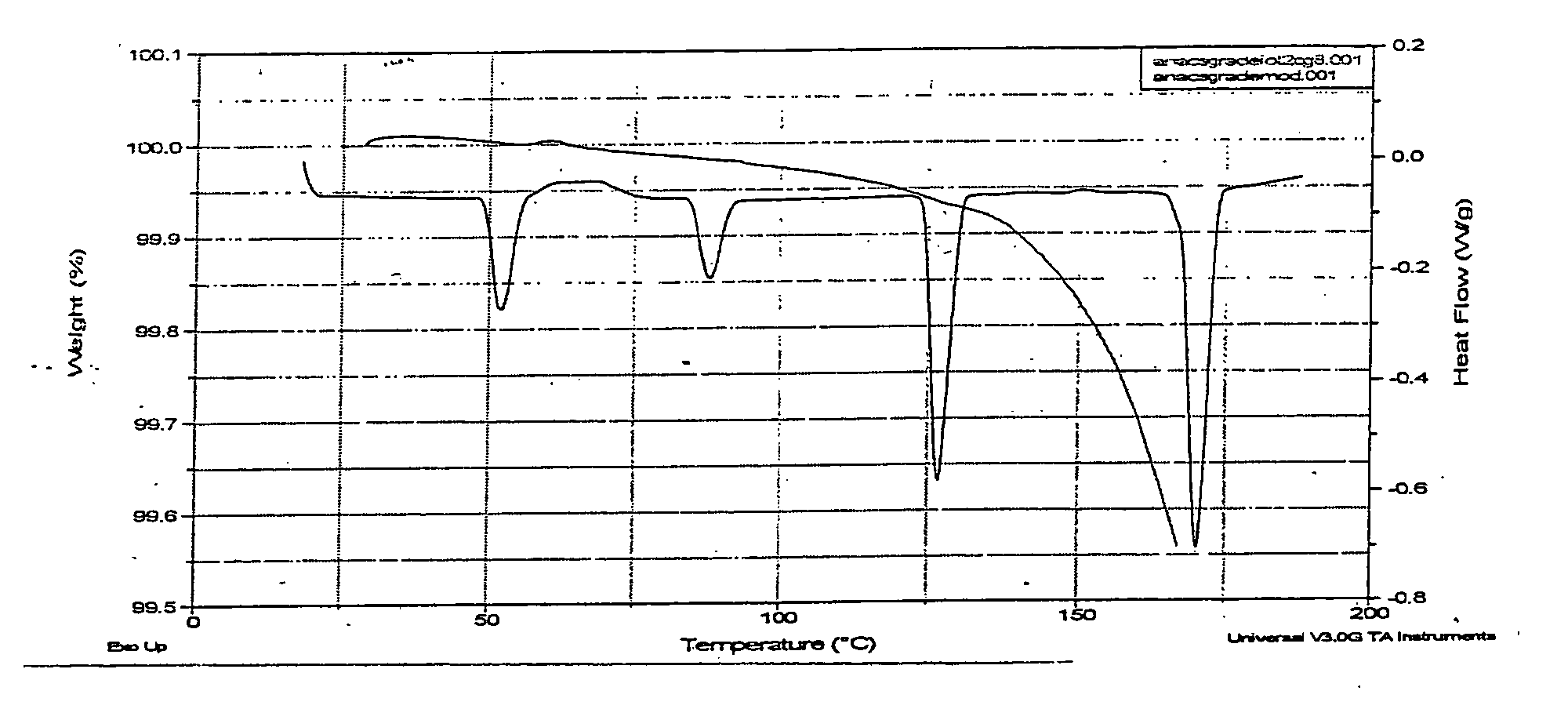

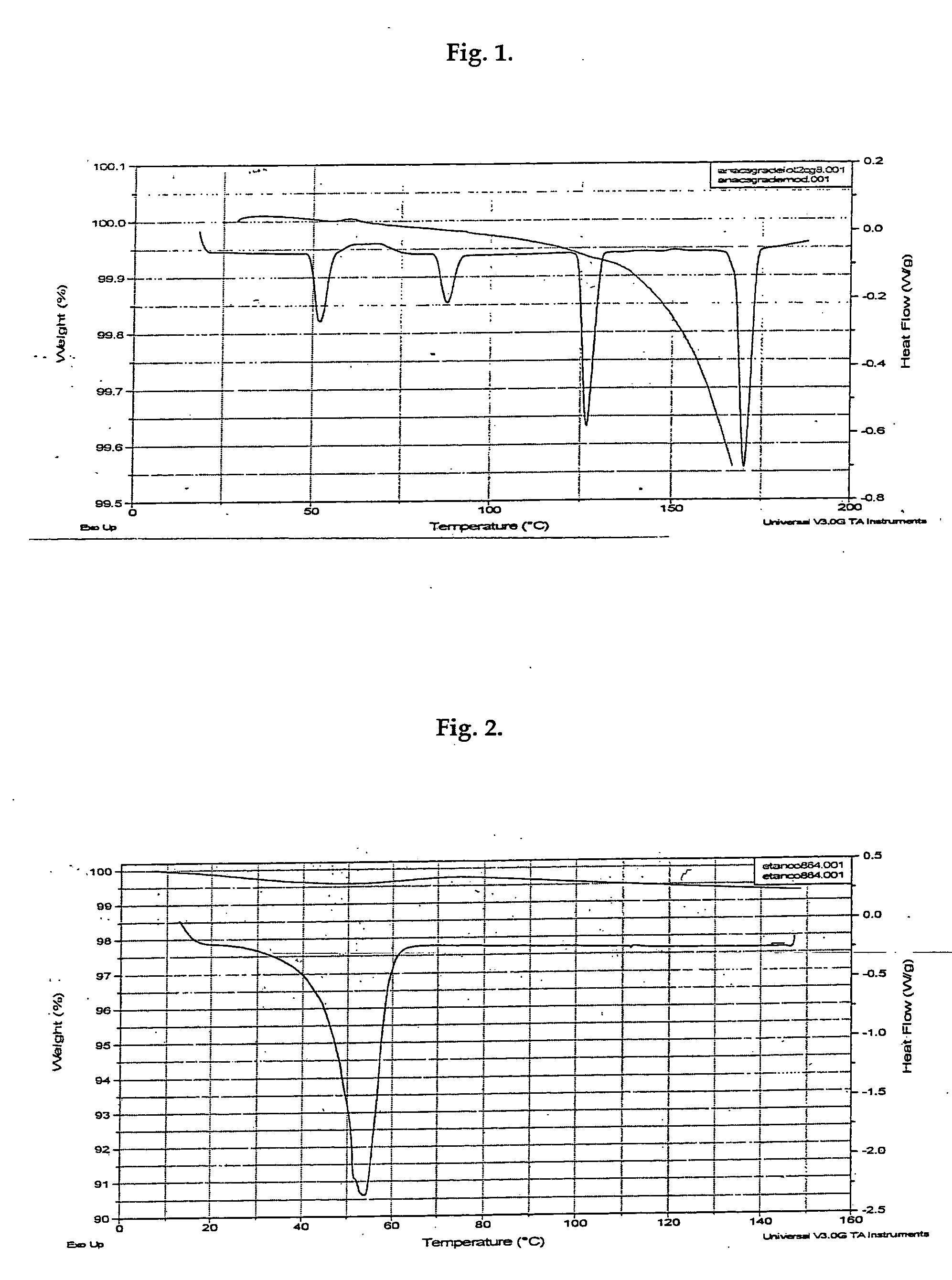

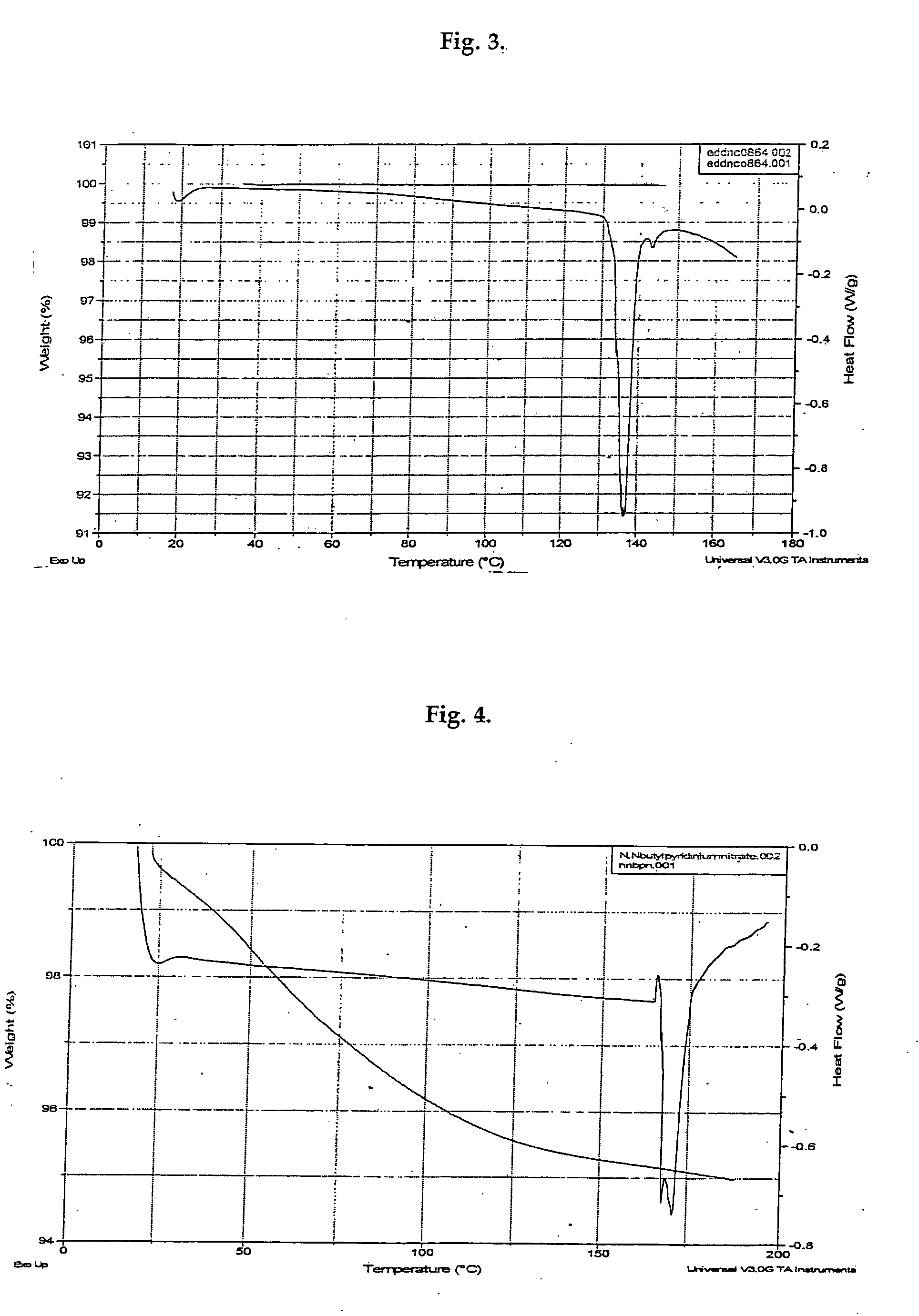

[0039] In general terms, the present invention comprises an ionomer oxidizer polymer binder, an oxidizer mix including at least one oxidizer salt and at least one eutectic material which maintains the oxidizer mix in liquid form at the process temperature, and a mobile phase comprising at least one ionic liquid. The present invention also includes certain changes to the general composition, including: (i) the use of a higher molecular weight (above 100,000) polymer, (ii) the controlled cross-linking of the polymer, (iii) the use of a moisture barrier coating, (iv) the addition of an energetic material such as Chromium III, and (v) the addition of low molecular weight polyethylene glycol polymer.

[0040] In the preferred embodiments, the ionomer oxidizer binder is polyvinylammonium nitrate (PVAN). The oxidizer salt preferably comprises ammonium nitrate (AN). The eutectic additive for the oxidizer salt may comprise a variety of salts or mixtures thereof, and preferably comprises an ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com