Tree harvester assembly

a technology for assembling and harvesting trees, which is applied in the direction of agricultural machines, manufacturing tools, tractors, etc., can solve the problems of damage to the chain or the chain bar, the remaining portion of the tree in front of the chain saw cannot and the chain is too large to support the entire weight of the tr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

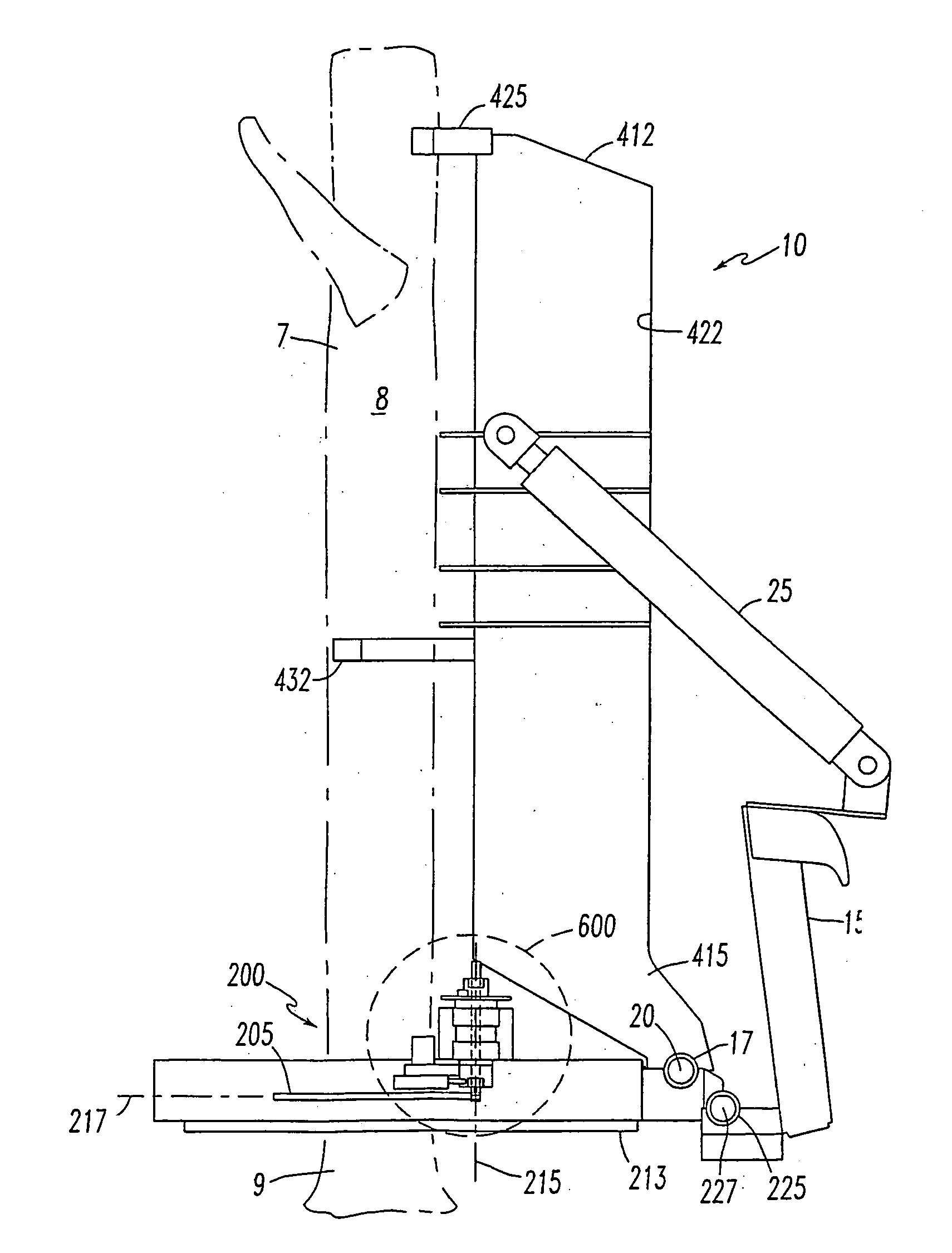

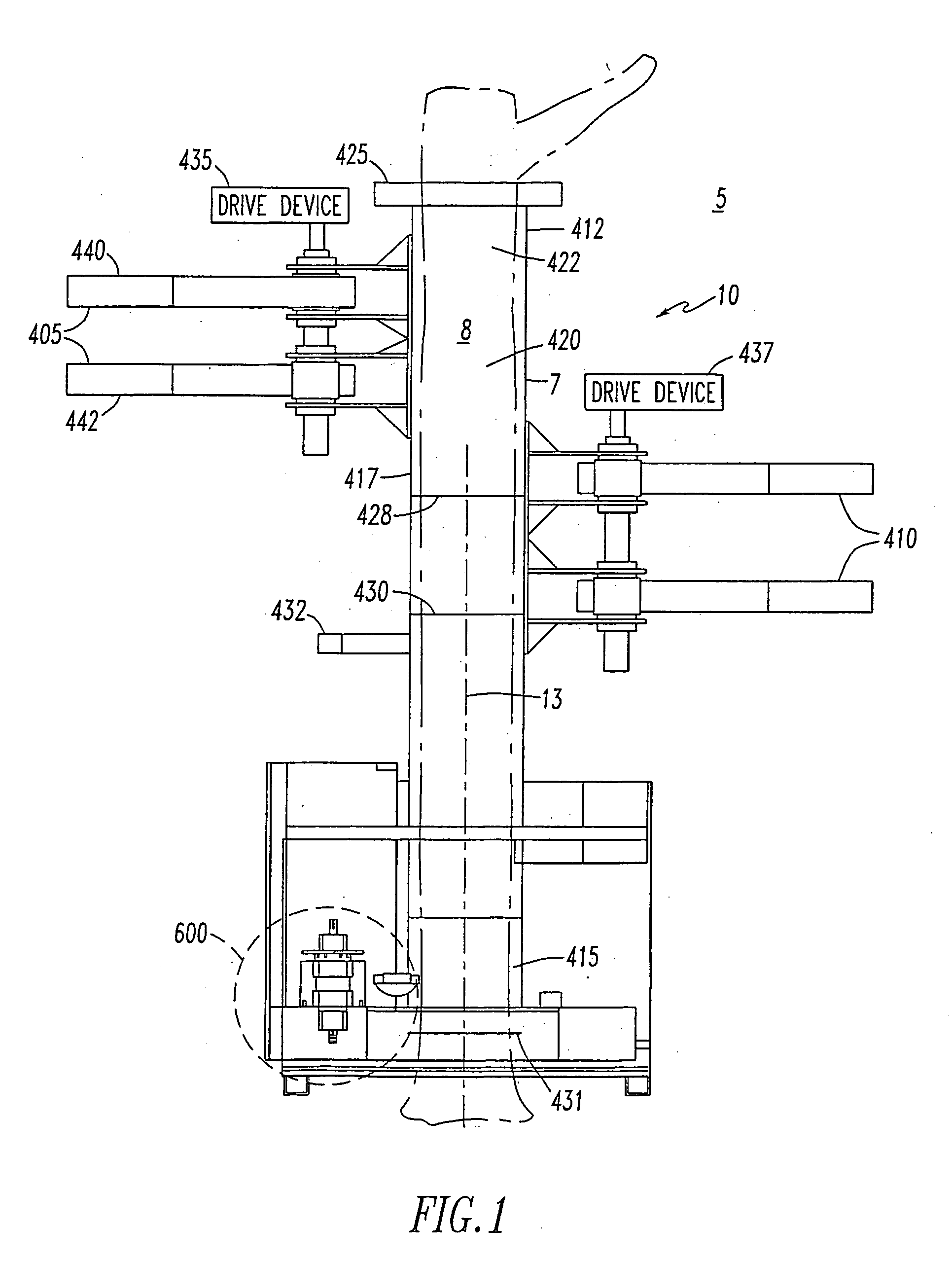

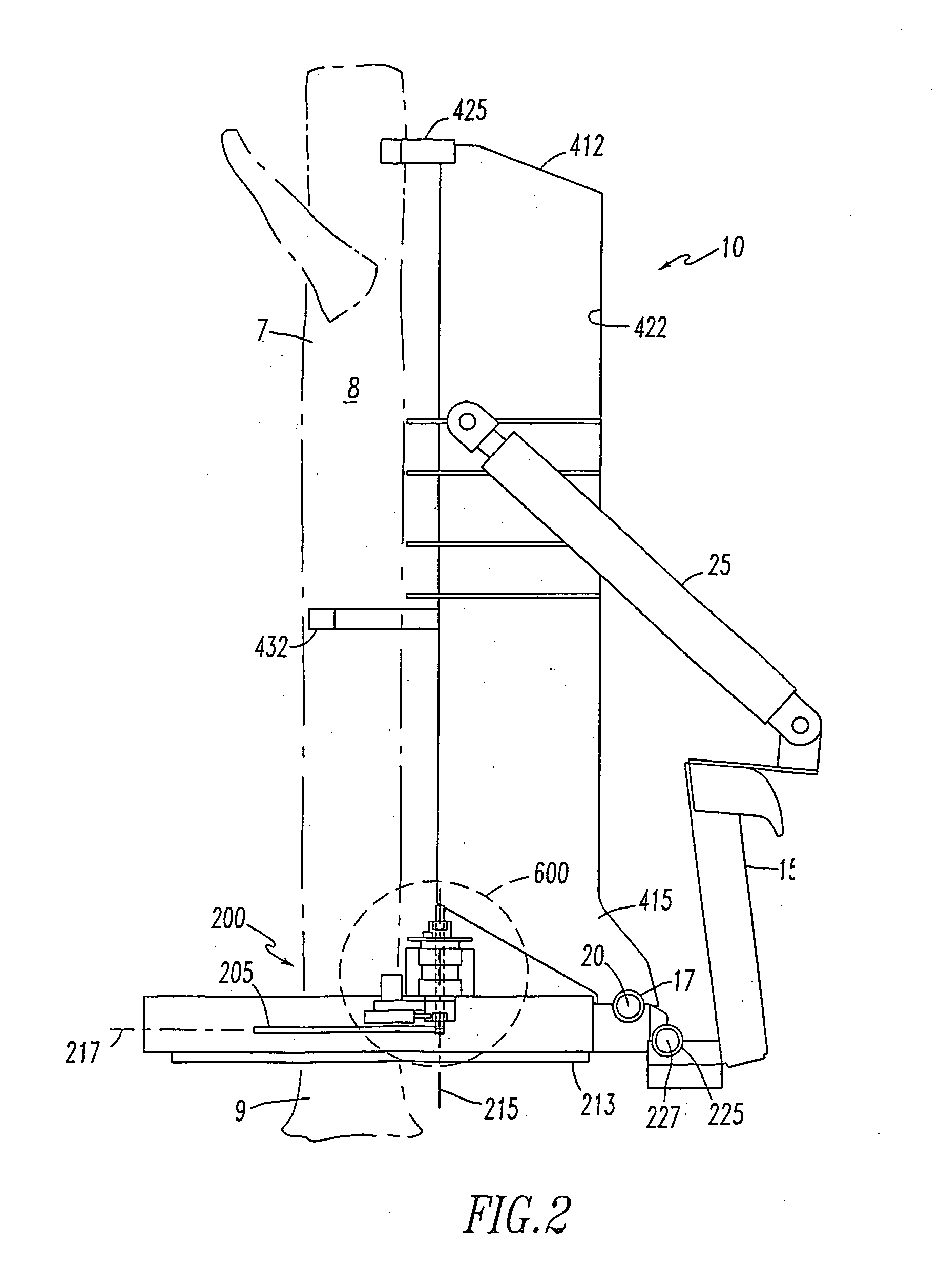

[0045]FIGS. 1-3 illustrate a front, side and top view of the tree harvester in accordance with the subject invention. The subject invention will be described in the context of five aspects, which include: [0046] 1) a pivoting securing tower 10; [0047] 2) a pivoting chain saw guide 200 (FIG. 2); [0048] 3) an arrangement 400 to secure a tree trunk within the tower 10 (FIG. 3); [0049] 4) a chain saw pivoting / driving apparatus 600 (FIG. 8); and [0050] 5) a chain saw tensioning device 800 (FIG. 8).

[0051] As a brief overview, the tree harvester 5 is positioned, as illustrated in FIG. 1, such that the securing tower 10 is adjacent to the trunk 7 of a tree 8. Clamping arms 405, 410 pivot inwardly to embrace the trunk 7 against the securing tower 10. A chain saw 205 (FIG. 2) is pivoted across the path of the trunk 7, thereby severing the trunk 7 from the base 9 of the tree. The trunk 7 is then moved by the securing tower 10 and deposited at a location suitable for further processing.

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com